Continuous production process of N-normal-butyl thiophosphoryl triamide

A technology for n-butyl thiophosphoric triamide and production process is applied in the field of continuous production technology of urease inhibitor N-n-butyl thiophosphoric triamide, and can solve the problems of high cost, large pollution and complicated process and other problems, to achieve the effects of low production cost, less side reactions, and increased reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

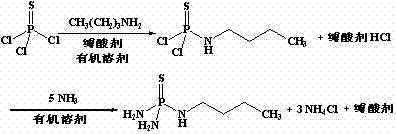

Method used

Image

Examples

Embodiment 1

[0024] Mix 10.20kg (60.18mol) of phosphorus trichloride and 30L of chlorobenzene to form component A, and mix 4.50kg (61.64mol) of n-butylamine and 11.40kg (61.62mol) of tri-n-butylamine and 30L of chlorobenzene to form component A. Part B. Transport components A and B to the Y-type jet mixer respectively, and enter the first tubular reactor after mixing. The reaction temperature is controlled at 35°C, and the residence time is 80s. After the reaction, the reaction liquid enters the preheated to 60°C In the pipeline, the preheated reaction solution enters the second tubular reactor, and 6.7kg of ammonia gas (394mol) is continuously introduced, and the reaction temperature is controlled to be 70°C, and the residence time is 1200s. After the reaction, the reaction solution is added to cold water to fully Stir and mix, enter the layered kettle, and let it stand for layering. The organic layer was washed once with water, chlorobenzene was recovered by vacuum distillation, the rec...

Embodiment 2

[0028] Mix 10.20kg (60.18mol) of phosphorus trichloride with 26L of o-dichlorobenzene to form component A, 4.46kg (61.09mol) of n-butylamine, 6.94kg (61.42mol) of N-ethylpiperidine and 30L of o-dichlorobenzene Chlorobenzene mixed evenly is component B. Transport components A and B to the Y-type jet mixer respectively, and enter the first tubular reactor after mixing. The reaction temperature is controlled at 40°C, and the residence time is 60s. After the reaction, the reaction liquid enters the preheated to 60°C In the pipeline, the preheated reaction solution enters the second tubular reactor, and 6.5kg of ammonia gas (382mol) is continuously introduced, and the reaction temperature is controlled to be 75°C, and the residence time is 900s. After the reaction is completed, the reaction solution is added to cold water to fully Stir and mix, enter the layered kettle, and let it stand for layering. The organic layer was washed once with water, and N-ethylpiperidine was recovered...

Embodiment 3

[0032] Mix 10.20kg (60.18mol) of phosphorus trichloride and 32L of diethyl carbonate to form component A, 4.35kg (59.59mol) of n-butylamine, 8.12kg (60.15mol) of N,N-dimethylbenzylamine and Mix 24L of diethyl carbonate evenly to form component B. Transport components A and B to the Y-type jet mixer respectively, and enter the first tubular reactor after mixing. The reaction temperature is controlled at 25°C, and the residence time is 180s. After the reaction, the reaction liquid enters the preheated to 60°C In the pipeline, the preheated reaction solution enters the second tubular reactor, continuously feeds 6.8kg of ammonia (400mol), controls the reaction temperature to be 70°C, and has a residence time of 1000s. After the reaction, the reaction solution is added to cold water to fully Stir and mix, enter the layered kettle, and let it stand for layering. The organic layer was washed once with water, diethyl carbonate was recovered by distillation under reduced pressure, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com