High-silicon composite molecular sieve adsorbent for removing VOCs and preparation method of high-silicon composite molecular sieve adsorbent

A composite molecular sieve and adsorbent technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult to meet VOCs waste gas treatment, poor hydrothermal stability, low hydrophobicity, etc., to improve the utilization of molecular sieves. High efficiency, high hydrophobicity, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

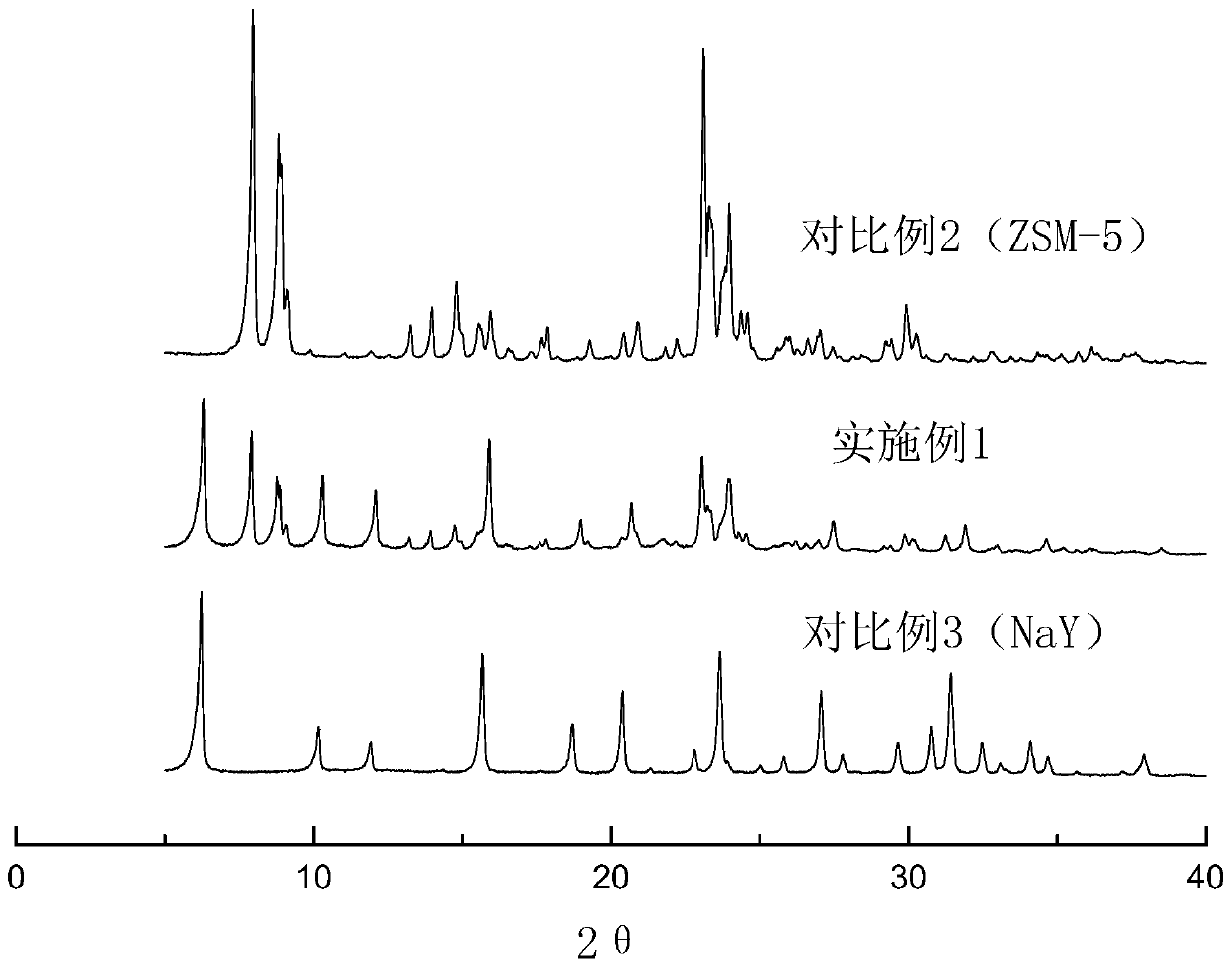

[0050] The preparation method of the high-silicon composite molecular sieve adsorbent for VOCs removal at least includes the following steps:

[0051] Step 1, the aluminum source Ⅰ, alkali source Ⅰ and H 2 O is mixed and added to the silicon source I, stirred evenly to obtain a mixture, and the obtained mixture is subjected to aging treatment in an ultrasonic state to prepare a Y-type molecular sieve guiding agent.

[0052] Step 2, the H 2 O. Alkaline source II and aluminum source II are mixed, and n-butylamine and silicon source II are added to it to obtain a precursor material, which is subjected to crystallization reaction under microwave condition I to prepare ZSM-5 crystalline suspension Cloudy liquid.

[0053] Step 3. Add Y-type molecular sieve directing agent with a volume fraction of 5%-10% to the ZSM-5 crystallization suspension, as well as aluminum source III and H 2 O, a mixed system is formed after being mixed uniformly; in this mixed system, Na 2 O, Al 2 o 3...

Embodiment 1

[0089] Step 1. Mix sodium aluminate, sodium hydroxide and deionized water at room temperature, and stir evenly. The stirring time is controlled for 1 hour. After the system solution is transparent, the sodium aluminate and sodium hydroxide are completely dissolved, and then It is added to a sodium silicate solution to obtain a mixture; wherein, sodium hydroxide (as Na 2 O), sodium aluminate (as Al 2 o 3 In terms of), sodium silicate solution (as SiO 2 The molar ratio of ) to deionization is 17:1:16:312; the obtained mixture is vigorously stirred for 20 minutes, and then aged at 30°C for 24 hours, and the stirring speed is 100r / min during the aging process. The aging treatment is accompanied by ultrasonic treatment, the ultrasonic power is 200W, the ultrasonic frequency is 40KHz, and the ultrasonic time is 24h, the Y-type molecular sieve guide agent can be prepared.

[0090]Step 2. Mix deionized water, sodium hydroxide and sodium aluminate. After stirring evenly, add templat...

Embodiment 2

[0099] Step 1. Mix aluminum sulfate, sodium hydroxide and deionized water at room temperature, and stir evenly. The stirring time is controlled for 1 hour. When the system solution is transparent, aluminum sulfate and sodium hydroxide are completely dissolved, and then add In sodium silicate solution, obtain mixture; Among them, sodium hydroxide (as Na 2 O), aluminum sulfate (as Al 2 o 3 In terms of), sodium silicate solution (as SiO 2 The molar ratio of ) and deionization is 15:1:16:312; the obtained mixture is vigorously stirred for 20 minutes, and then aged at 60°C for 1 hour, and the stirring speed is 100r / min during the aging process. The aging treatment is accompanied by ultrasonic treatment, the ultrasonic power is 1000W, the ultrasonic frequency is 50KHz, and the ultrasonic time is 1h, the Y-type molecular sieve guide agent can be prepared.

[0100] Step 2. Mix deionized water, sodium hydroxide and sodium aluminate. After stirring evenly, add template agent n-butyla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com