Method for forming conductive film at room temperature

a technology of conductive film and room temperature, which is applied in the direction of liquid/solution decomposition chemical coating, coating, special surfaces, etc., can solve the problems of low cost, non-heat-resistant flexible substrate (i.e. pet substrate), and the method cannot be used to conveniently and rapidly print, so as to increase the application potential of silver nanoparticles, low cost, and convenient and rapid printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The structure and the technical means adopted by the present invention to achieve the above and other objects can be best understood by referring to the following detailed description of the preferred embodiments and the accompanying drawings. Furthermore, directional terms described by the present invention, such as upper, lower, front, back, left, right, inner, outer, side, longitudinal / vertical, transverse / horizontal, and etc., are only directions by referring to the accompanying drawings, and thus the used directional terms are used to describe and understand the present invention, but the present invention is not limited thereto.

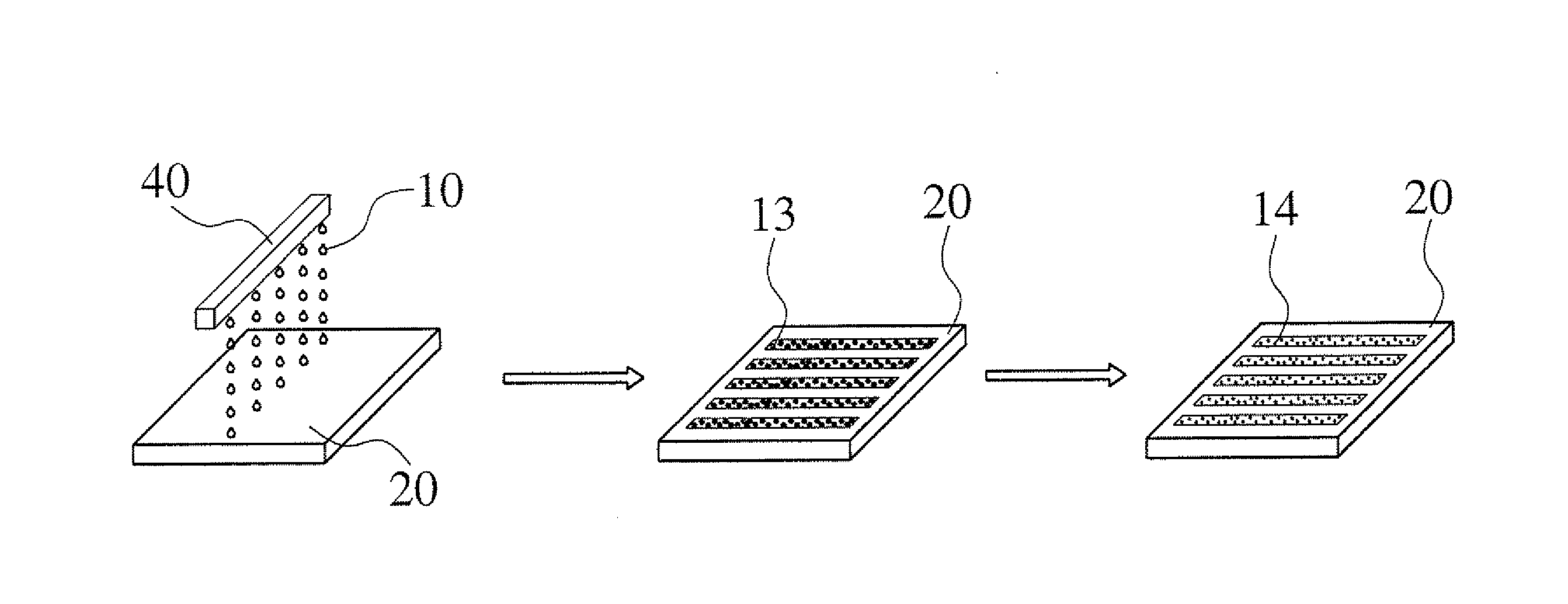

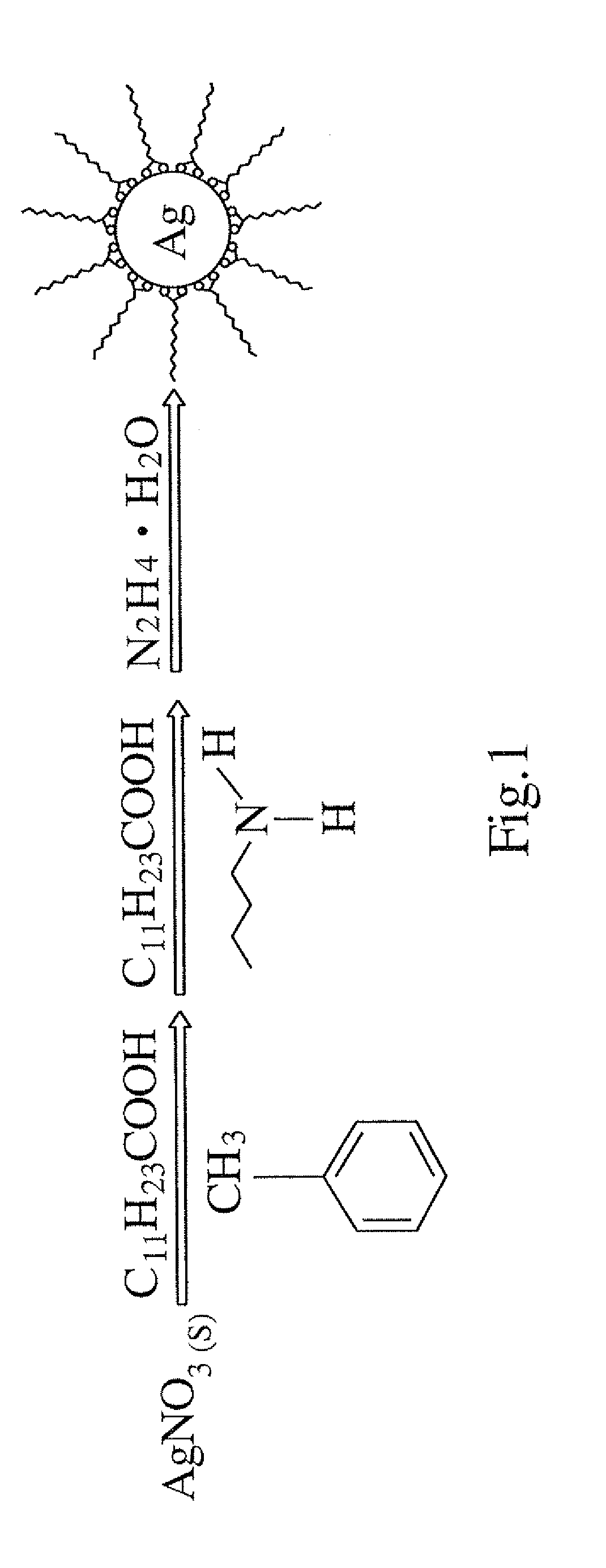

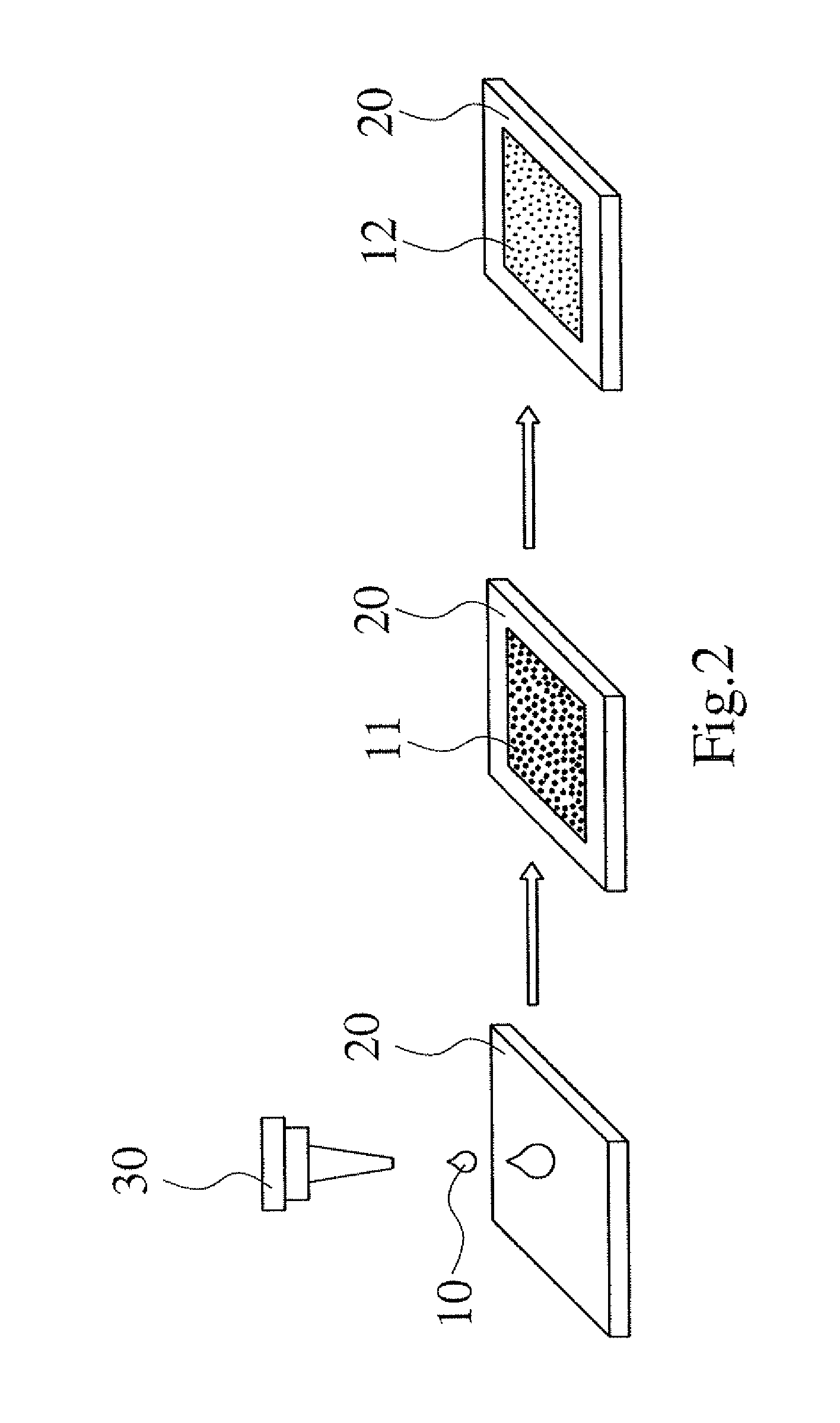

[0036]Please refer to FIGS. 1 to 3, a method for forming a conductive film at room temperature according to a first embodiment of the present invention mainly comprises the following steps: (a) adding AgNO3 into a non-polar solvent containing dodecanoic acid (C11H23COOH, also known as n-dodecanoic acid) to be a first mixture; (b) dropping n-butyla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com