Portable no-key-hole friction stir spot welding equipment with self-holding function

A technology of friction stir and spot welding equipment, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of limited working area and working dimension, weak adaptability of welding thickness, inability to meet, etc., to reduce physical fitness and operating technology requirements, the effect of improving welding quality and productivity, enhancing flexibility and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

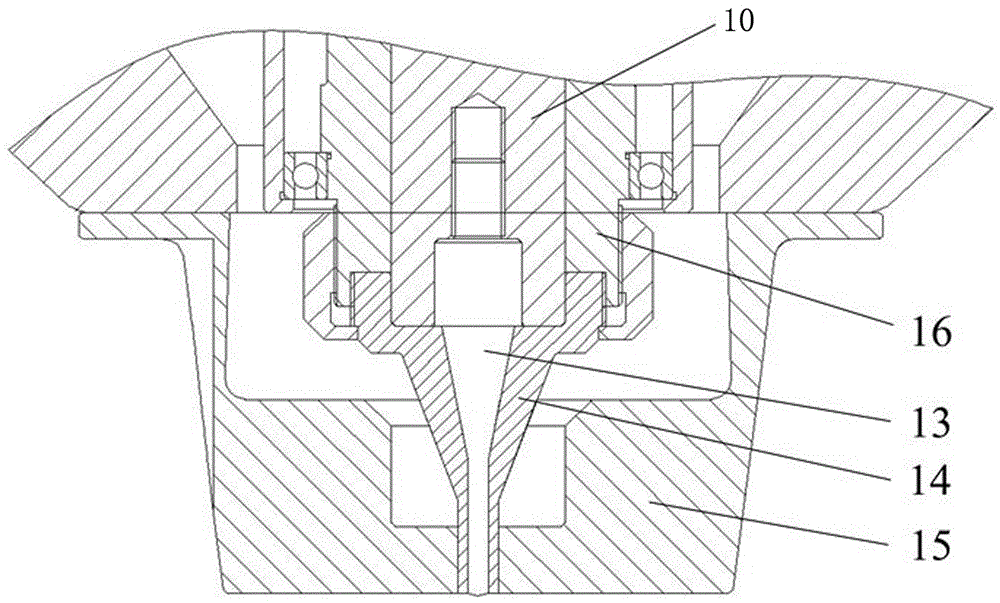

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

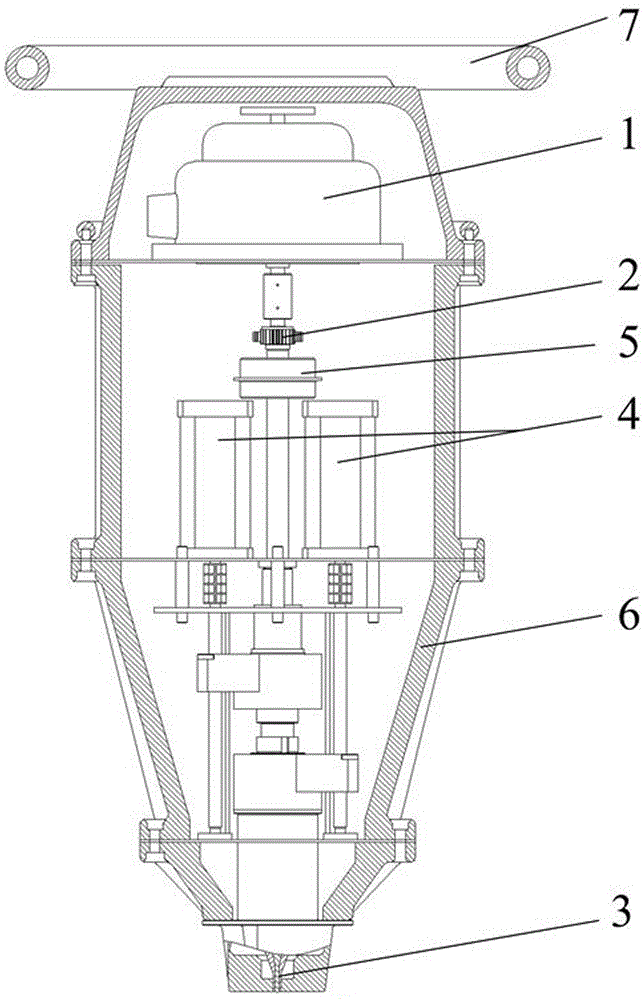

[0020] A portable keyhole-less friction stir spot welding device with a self-contained function, such as figure 1 As shown, an outer casing 6 is included, and a power motor 1 , a transmission mechanism 2 , a welding mechanism 3 and a servo mechanism 4 are installed in the outer casing 6 ;

[0021] The power motor 1 is preferably a three-phase asynchronous disc brake motor, and the output shaft of the power motor 1 is provided with a brake 5 to realize electrical-mechanical combined braking, thereby more effectively protecting the safety of welding equipment and operators.

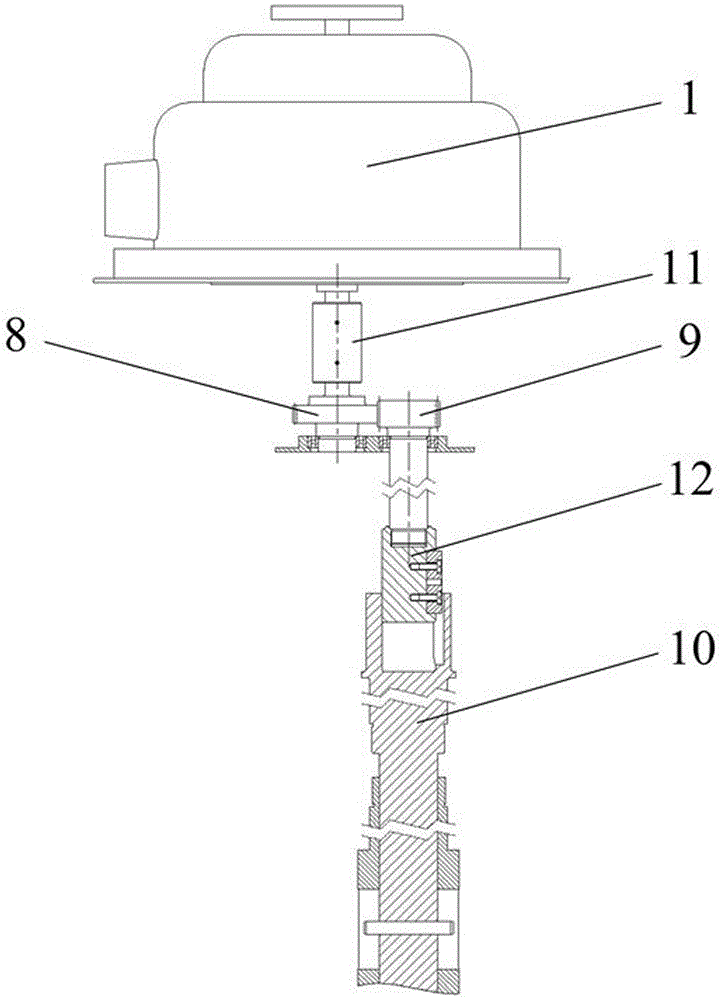

[0022] Such as figure 2 As shown, the transmission mechanism 2 includes a driving shaft gear 8 and a driven shaft gear 9 meshingly connected; the driving shaft gear 8 is connected to the output shaft of the power motor 1 through a sleeve coupling 11; the driven shaft gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com