Surface-modified heterogeneous knot titanium dioxide photonic crystal catalyst and preparation thereof

A technology of photonic crystals and titanium dioxide, which is applied in the field of catalysis, can solve the problems of enhanced visible light catalytic ability of catalysts, difficulty in photocatalyst environmental purification, and decreased ultraviolet photocatalytic ability, so as to improve visible light catalytic ability, enhance visible light response, and enhance visible light chemical reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the above-mentioned surface-modified heterojunction titanium dioxide photonic crystal thin film catalyst also proposed by the present invention comprises the following steps:

[0040] S1. After mixing the indium nitrate solution and formic acid evenly, add Ti(OC 2 h 5 ) 4 , then add nitric acid and stir to obtain stable and transparent TiO 2 Sol; the volume ratio of the titanium-containing material to the diluent is 1:10, and the molar ratio of the titanium content in the titanium-containing material to the indium content in the indium salt is 100:5;

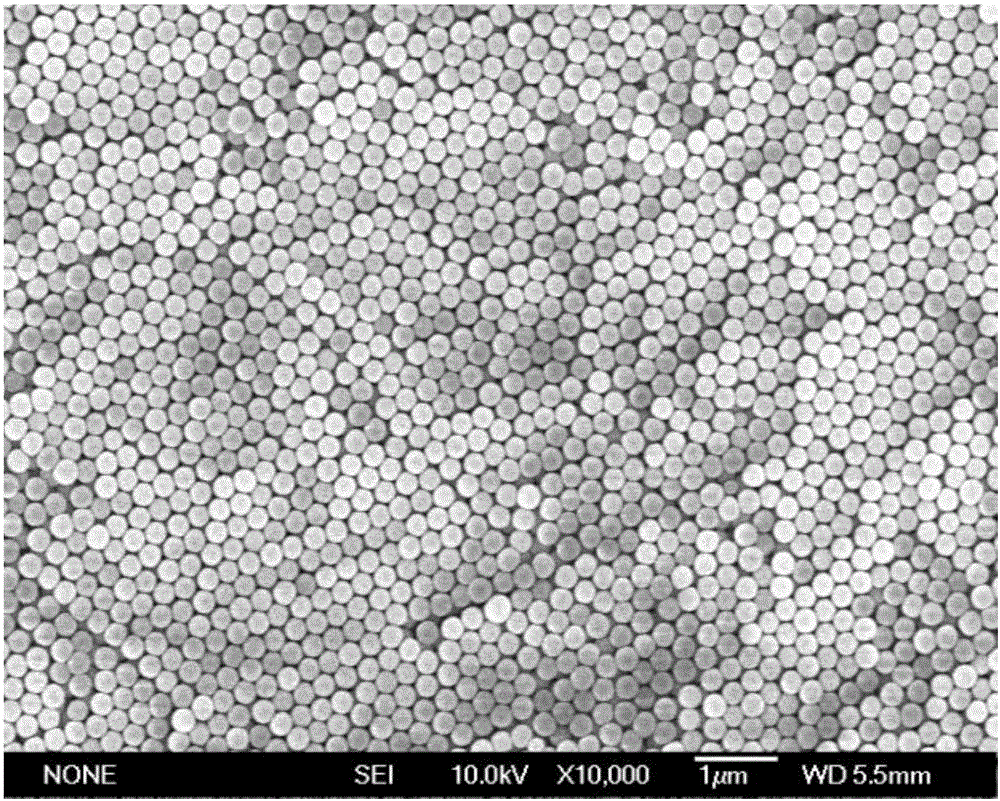

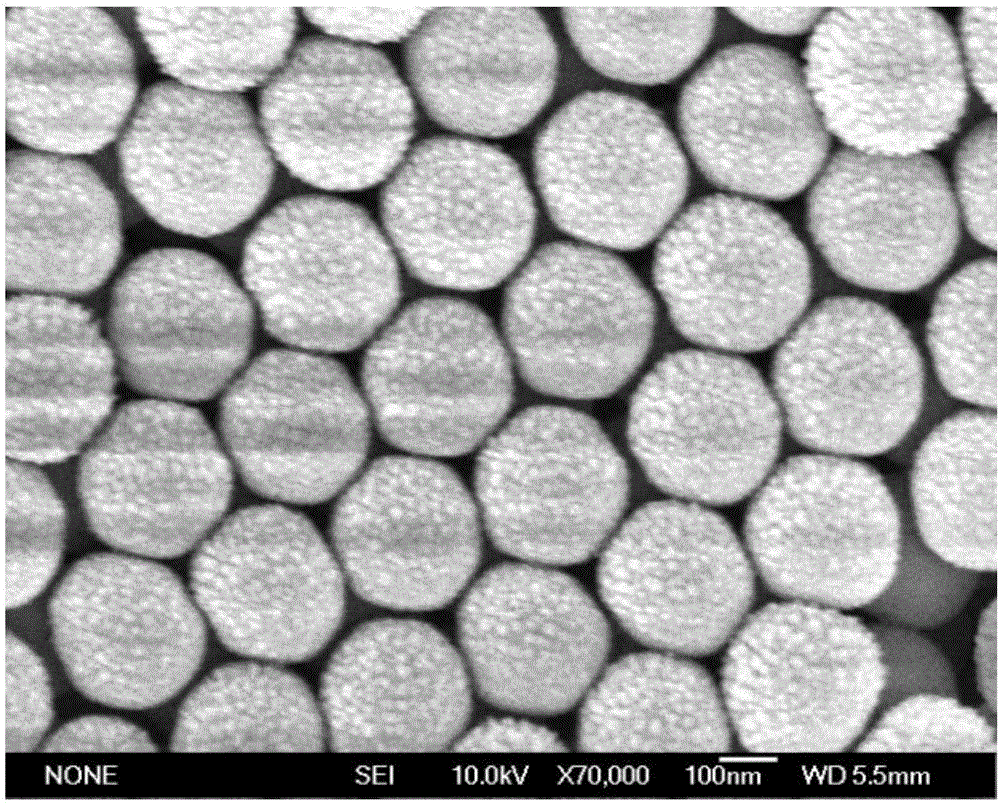

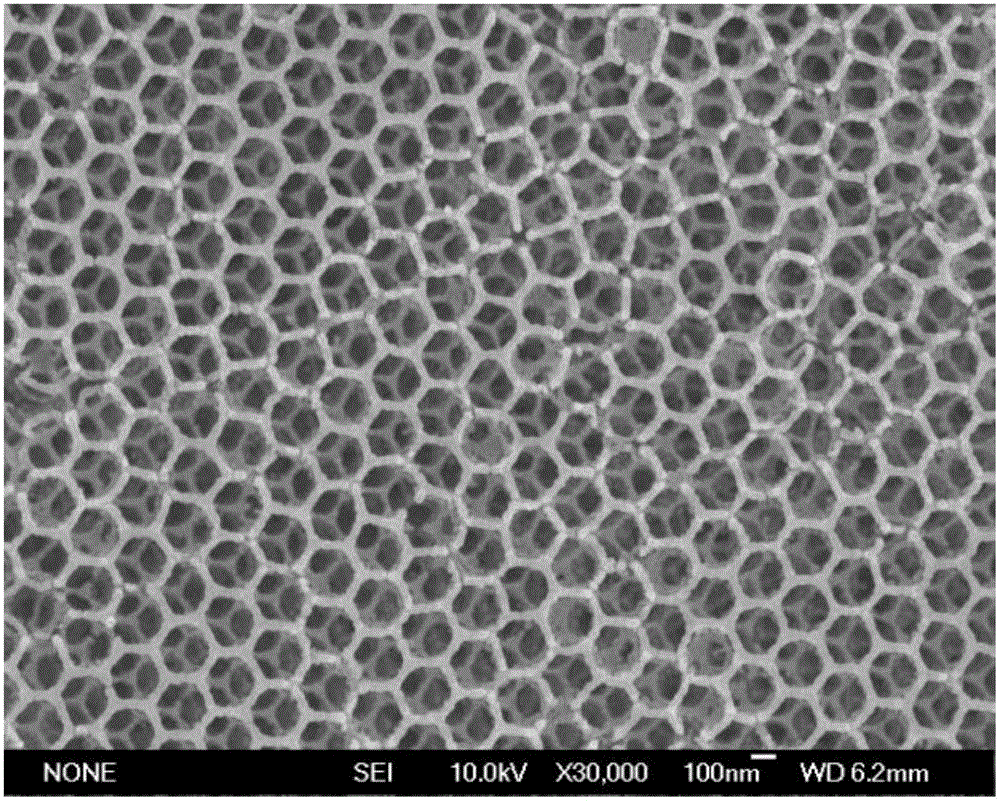

[0041] S2. Vertically insert the cleaned glass slide into the polystyrene suspension with a volume fraction of 0.15%, then place the polystyrene suspension containing the glass slide in a thermostat, and adjust the temperature to 60°C. After the solvent is completely evaporated, take out the glass slide containing polystyrene, then raise the temperature to 80°C, and keep it warm for 1.5h to ob...

Embodiment 2

[0045] The preparation method of the above-mentioned surface-modified heterojunction titanium dioxide photonic crystal thin film catalyst also proposed by the present invention comprises the following steps:

[0046] S1. After mixing the indium sulfate solution and glacial acetic acid evenly, add Ti(iso-OC 3 h 7 ) 4 and Ti(SO 4 ) 2 , then add sulfuric acid and stir to obtain stable and transparent TiO 2 Sol; the volume ratio of the titanium-containing material to the diluent is 5:10, and the molar ratio of the titanium content in the titanium-containing material to the indium content in the indium salt is 100:0.1;

[0047] S2. Vertically insert the cleaned glass slide into the polystyrene suspension with a volume fraction of 0.5%, then place the polystyrene suspension containing the glass slide in a thermostat, and adjust the temperature to 50°C. After the solvent is completely evaporated, take out the glass slide containing polystyrene, then raise the temperature to 80°C...

Embodiment 3

[0051] The preparation method of the above-mentioned surface-modified heterojunction titanium dioxide photonic crystal thin film catalyst also proposed by the present invention comprises the following steps:

[0052] S1. After mixing the indium acetate solution and anhydrous methanol evenly, add TiCl dropwise under stirring 4 , then add glacial acetic acid, stir to get stable and transparent TiO 2 Sol; the volume ratio of the titanium-containing material to the diluent is 3:10, and the molar ratio of the titanium content in the titanium-containing material to the indium content in the indium salt is 100:2.5;

[0053] S2. Vertically insert the cleaned glass slide into the polystyrene suspension with a volume fraction of 0.3%, then place the polystyrene suspension containing the glass slide in a constant temperature box, and adjust the temperature to 55°C. After the solvent is completely evaporated, take out the glass slide containing polystyrene, then raise the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com