An ag-doped 3dom CeO 2 -ZrO 2 material preparation

A 3domceo2-zro2, 3·6H2O technology, applied in the chemical industry, can solve problems such as low utilization of sunlight, achieve large specific surface area, improve photocatalytic activity, and increase the effect of migration pathways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

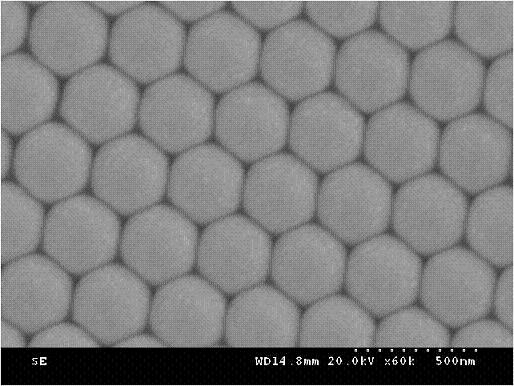

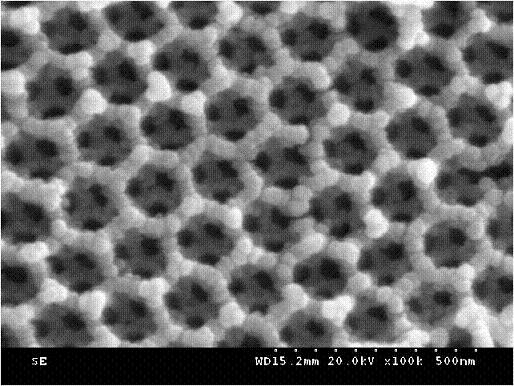

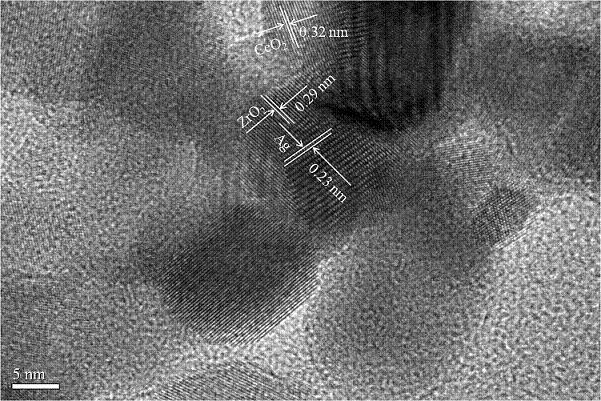

[0017] Synthesis of Ag-Doped 3DOM CeO by Decompression Filling Method 2 -ZrO 2 The composite photocatalyst was weighed from 99.0% Ce(NO) purchased from Tianjin Kemeiou Chemical Reagent Co., Ltd. 3 ) 3 ·6H 2 O, the mass is Ce (NO 3 ) 3 ·6H 2 O, 0.167±0.002 g, and 99.8% AgNO purchased from Tianjin Guangfu Institute of Fine Chemicals 3 , the mass of 0.023 ± 0.001 g was dissolved in 99.7% IPA purchased from Tianjin Guangfu Institute of Fine Chemicals, and the volume was 2 mL for use. The P123 of Mn~5800 purchased from Shanghai Saen Chemical Technology Co., Ltd., with a mass of 0.050 ± 0.005 g, was added to 15 mL of IPA with a volume of 15 mL and stirred until completely dissolved, and then added dropwise and purchased from Shanghai Merrill Chemical Technology Co., Ltd. 80.0% Zr(OC 4 H 9 ) 4 , the volume was 1.5 mL, and then Ce(NO 3 ) 3 with AgNO 3 solution to form Ag / CeO 2 -ZrO 2 Sol, PS template (synthesized by emulsifier-free emulsification method, and obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com