A kind of n, ti 3+ Co-doped visible-light photocatalytic tio 2 Preparation method of nanotube array

A nanotube array and visible light technology, applied in the field of nanomaterials, can solve problems such as non-reduction, and achieve the effects of simple process, saving of raw materials and equipment, and removal of refractory organic pollutants by strong visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) After ultrasonically cleaning the pure titanium sheet with deionized water, immerse it in HF and HNO with a volume ratio of 1:3:6 3 、H 2 Etched in O mixed solution for 1 min, rinsed with deionized water immediately, and dried in nitrogen flow; weighed 0.37 g of NH 4 F is dissolved in a mixture of 90ml ethylene glycol and 10ml deionized water and configured as NH 4 F concentration is the electrolytic solution of 0.1mol / L; With the treated titanium sheet as the anode and the platinum sheet as the cathode, carry out the anodic oxidation reaction at 20V DC voltage for 0.5h, after the reaction is finished, wash with deionized water, and Dry in air to obtain amorphous TiO 2 nanotube arrays;

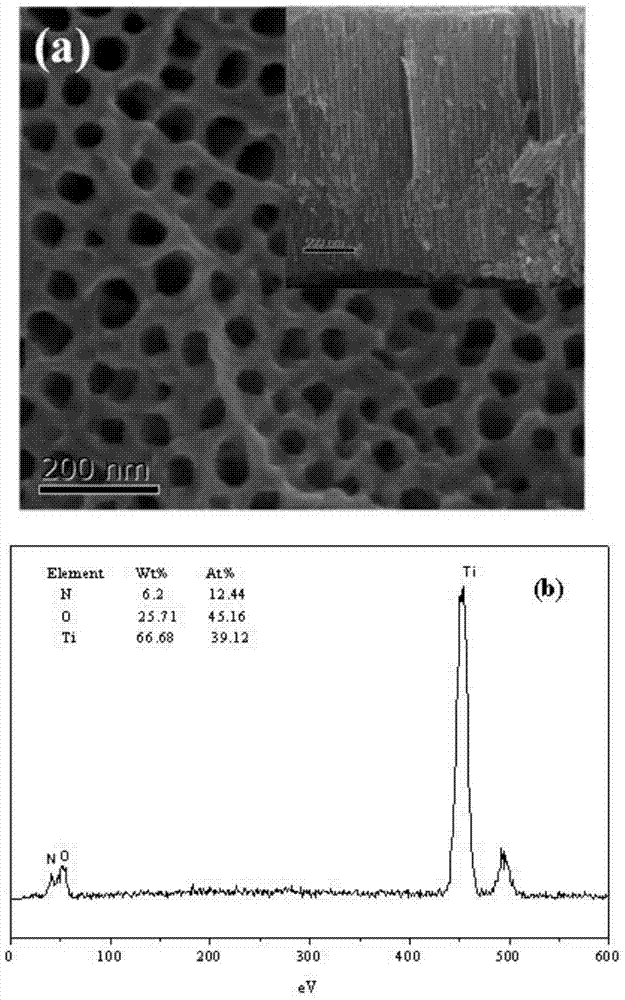

[0028] (2) the amorphous TiO 2 The nanotubes were suspended above 0.1g melamine, put into a muffle furnace and calcined at 450°C for 2h to crystallize and prepare N-doped TiO 2 After testing, its SEM image and EDS spectrum are as follows figure 1 shown in;

[0029] (3) With pl...

Embodiment 2

[0037] (1) After ultrasonically cleaning the pure titanium sheet with deionized water, immerse it in HF and HNO with a volume ratio of 1:3:6 3 、H 2 Etched in O mixed solution for 1min, rinsed with deionized water immediately, and dried in nitrogen flow; weighed 2.96g of NH 4 F is dissolved in a mixture of 90ml ethylene glycol and 10ml deionized water and configured as NH 4 Electrolyte with F concentration of 0.8mol / L; take the treated titanium sheet as anode and platinum sheet as cathode, and carry out anodic oxidation reaction at 35V DC voltage for 2h. After the reaction, wash with deionized water and dry in air dry in medium to obtain amorphous TiO 2 nanotube arrays;

[0038] (2) the amorphous TiO 2 The nanotubes were suspended above 0.7g melamine, put into a muffle furnace and calcined at 500°C for 2h to crystallize and prepare N-doped TiO 2 ;

[0039] (3) With platinum sheet as anode, crystallized TiO 2 The nanotube is the cathode, 2.5mol / L Na 2 SO 4 The solution ...

Embodiment 3

[0041] (1) After ultrasonically cleaning the pure titanium sheet with deionized water, immerse it in HF and HNO with a volume ratio of 1:3:6 3 、H 2 Etched in O mixed solution for 1min, rinsed with deionized water immediately, and dried in nitrogen flow; weighed 5.55g of NH 4 F is dissolved in a mixture of 90ml ethylene glycol and 10ml deionized water and configured as NH 4 Electrolyte with F concentration of 1.5mol / L; take the treated titanium sheet as anode and platinum sheet as cathode, and carry out anodic oxidation reaction at 50V DC voltage for 4h. dry in medium to obtain amorphous TiO 2 nanotube arrays;

[0042] (2) the amorphous TiO 2 The nanotubes were suspended above 1 g of melamine, and placed in a muffle furnace for calcination at 550 °C for 2 h to crystallize and prepare N-doped TiO 2 ;

[0043] (3) With platinum sheet as anode, crystallized TiO 2 Nanotube as cathode, 5mol / L Na 2 SO 4 The solution is an electrolyte, and an external -2V DC voltage is applie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com