Method for synthesizing ZSM-35 molecular sieve

A ZSM-35, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, iron conglomerate crystalline aluminum silicate zeolite, etc., can solve the problem of high prices of template agents and silicon and aluminum sources, and reduce production costs and methods. Simple, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Kaolin (Suzhou Kaolin from China Kaolin Corporation, the same below) was roasted to 950°C (abbreviated as GL950, SiO 2 / Al 2 o 3 = 14.7).

[0016] 4.84g silica sol (containing 30wt% SiO 2 ) and 13.51g of deionized water were successively added to a 30ml crystallization kettle, stirred evenly, then 7.0gGL950 was added, fully stirred evenly, and 1.23gNaOH (30wt%) and 0.48g n-butylamine (NBA) were added dropwise with stirring to obtain a reaction Mixture, its molar ratio is:

[0017] SiO 2 0.033Al 2 o 3 0.07Na 2 O·15H 2 O 0.1NBA

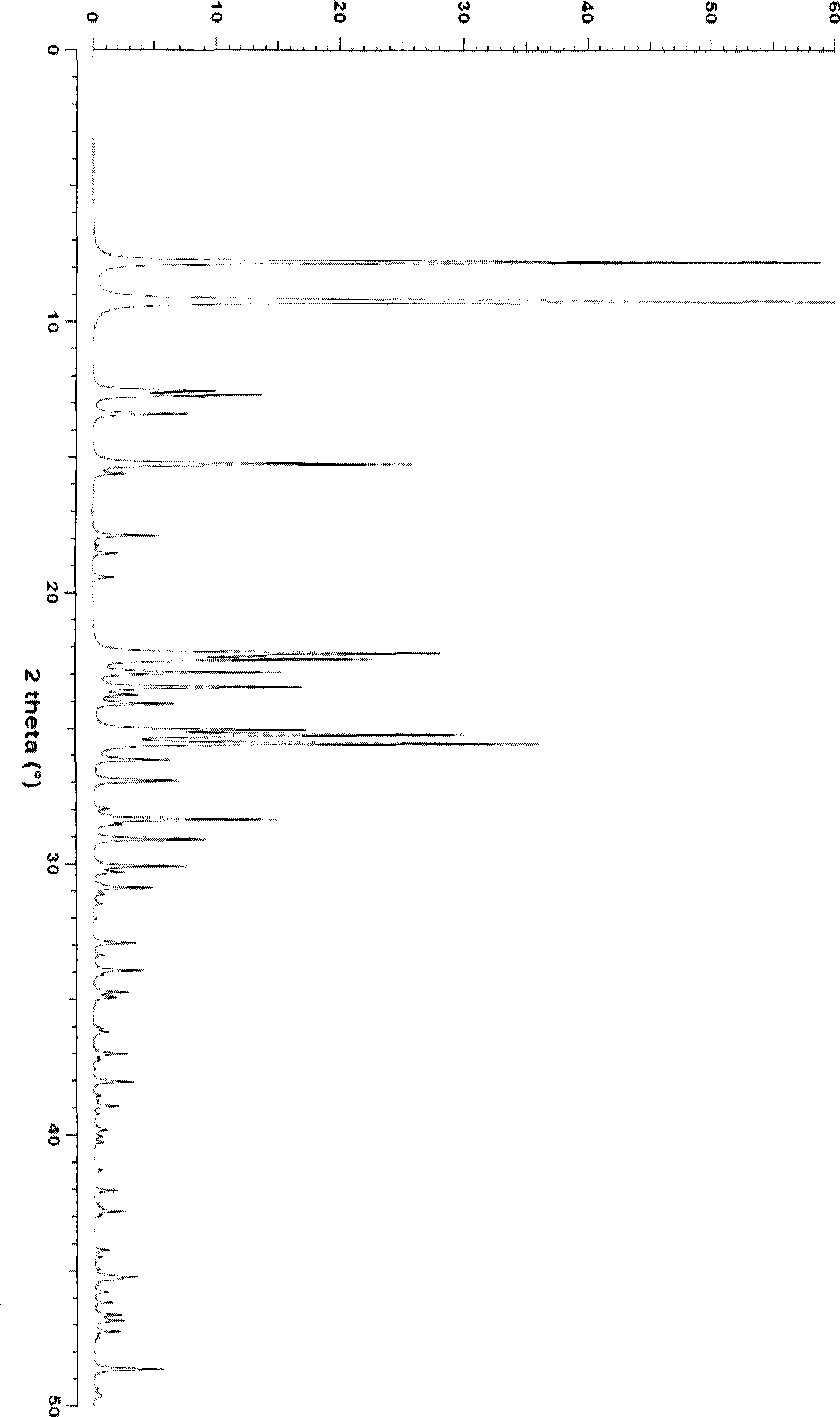

[0018] The reaction mixture was stirred evenly, moved into a reaction kettle, and crystallized at 150°C for 48h under sealing. After cooling, the solid separated from the mother liquor. The separated solid was washed with deionized water until pH = 7-8, and dried at 100°C for 2 hours to obtain a sodium molecular sieve. The X-ray powder diffraction (XRD) crystal phase peak pattern was the same as that of the ZSM-35 standard spectrum, th...

Embodiment 2

[0020] 7.78g silica sol (containing 30wt% SiO 2 ) and 10.65g deionized water were successively added to a 30ml crystallization kettle, stirred evenly, then added 4.0gGL950, fully stirred evenly, and added 1.17gNaOH (30wt%) and 0.46gNBA with dropwise stirring to obtain a reaction mixture, its molar ratio for:

[0021] SiO 2 0.02Al 2 o 3 0.07Na 2 O·15H 2 O 0.1NBA

[0022] The reaction mixture was stirred evenly, moved into a reaction kettle, and crystallized at 150° C. for 48 h under sealing. After cooling, the solid separated from the mother liquor. The separated solid was washed with deionized water to refer to pH=7~8, and dried at 100° C. for 2 hours to obtain a sodium ZSM-35 molecular sieve. The X-ray powder diffraction (XRD) crystal phase peak type was identical to the ZSM-35 standard spectrum. That is, the obtained ZSM-35 molecular sieve.

Embodiment 3

[0024] 11.47g silica sol (containing 30wt% SiO 2 ) and 10.87g deionized water were successively added to a 30ml crystallization kettle, stirred evenly, then added 3.0gGL950, fully stirred evenly, and added 2.0gNaOH (30wt%) and 0.55gNBA with dropwise stirring to obtain a reaction mixture, its molar ratio for:

[0025] SiO 2 0.013Al 2 o 3 0.1Na 2 O·15H 2 O 0.1NBA

[0026] The reaction mixture was stirred evenly, moved into a reaction kettle, and crystallized at 150° C. for 48 h under sealing. After cooling, the solid separated from the mother liquor. The separated solid was washed with deionized water to refer to pH = 7-8, and dried at 100°C for 2 hours to obtain a sodium-type ZSM-35 molecular sieve. The X-ray powder diffraction (XRD) crystal phase had the same characteristics as the ZSM-35 standard spectrum, namely It is ZSM-35 molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com