Surface modification glass fiber and preparation method and application thereof

A glass fiber and surface modification technology, applied in the field of surface modified fiber and its preparation, can solve problems such as difficulty in industrialization, and achieve the effects of increasing interface bonding, increasing deformability, and improving modulus and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

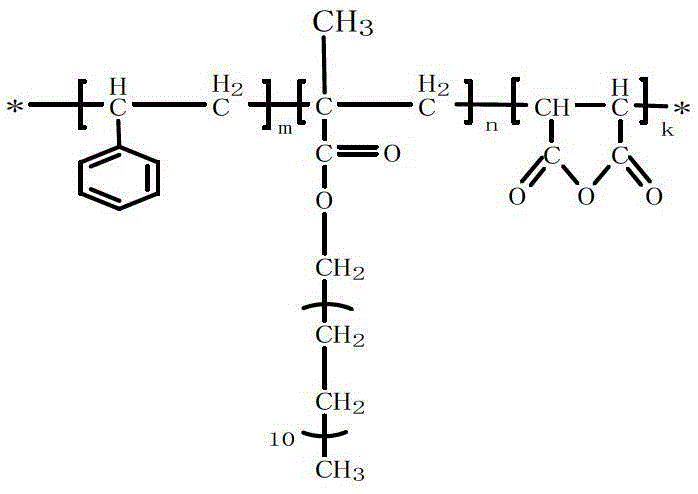

[0024] Preparation of the copolymer: Weigh 12.7g lauryl methacrylate, 5.2g styrene, 4.9g maleic anhydride, 0.1368g benzoyl peroxide, measure 25mL toluene, add them into a three-necked flask, stir fully, Nitrogen was blown, the temperature was raised to 60°C, and the reaction was carried out for 6h. After the reaction, remove the toluene by rotary evaporation, precipitate with petroleum ether, filter with suction, put the product in a vacuum drying oven, and dry for 8 hours to obtain the copolymer;

[0025] Pretreatment of glass fiber: take 50mL of 1% ethanol aqueous solution, measure 1mL of KH550, mix well in a beaker, let it stand for 20 minutes, add 6g of glass fiber, soak for 0.2h, take out the glass fiber, dry it in a fume hood, 70 Dry at ℃ for later use; surface modification of glass fiber: take the copolymer, add tetrahydrofuran to prepare a solution with a weight ratio of 1% tetrahydrofuran, add pretreated glass fiber, soak for 1.5h, take out the glass fiber, and dry it...

Embodiment 2

[0027]Preparation of copolymer: Weigh 25.4g lauryl methacrylate, 10.4g styrene, 4.9g maleic anhydride, 0.3256g azobisisobutyronitrile, measure 35mL toluene, add them into a three-necked flask, and stir thoroughly , Nitrogen, heated to 70 ° C, the reaction 7h. After the reaction, the toluene was removed by rotary evaporation, precipitated with petroleum ether, filtered with suction, the product was put into a vacuum drying oven, and dried for 8 hours to obtain a copolymer.

[0028] Glass fiber pretreatment: Measure 100mL of 1% ethanol aqueous solution, measure 1mL of KH550, mix well in a beaker, let stand for 12 minutes, add 24g of glass fiber, soak for 1h, take out the glass fiber, dry it in a fume hood, 80 ℃ dry for later use

[0029] Surface modification of glass fiber: take copolymer, add tetrahydrofuran, prepare a solution with a weight ratio of 2% tetrahydrofuran, add pretreated glass fiber, add pretreated glass fiber, soak for 1.5h, take out the glass fiber, and put it ...

Embodiment 3

[0031] Preparation of copolymer: Weigh 38.1g lauryl methacrylate, 10.4g styrene, 4.9g maleic anhydride, 0.534g benzoyl peroxide, measure 45mL benzene, add to a three-necked flask, stir fully, Nitrogen was blown, the temperature was raised to 80°C, and the reaction was carried out for 8h. After the reaction, remove benzene by rotary evaporation, precipitate with petroleum ether, filter with suction, put the product in a vacuum drying oven, and dry for 8 hours to obtain a copolymer.

[0032] Glass fiber pretreatment: Measure 70mL of 1% ethanol aqueous solution, measure 1mL of KH550, mix well in a beaker, let it stand for 10 minutes, add 10g of chopped glass fiber, soak for 2h, take out the glass fiber, and dry it in a fume hood , dried at 85°C for later use.

[0033] Surface modification of glass fiber: take copolymer, add tetrahydrofuran, prepare a THF solution with a weight ratio of 3%, add pretreated glass fiber, soak for 2 hours, take out the glass fiber, dry it in a fume h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com