Electron beam curing ink-jet ink as well as preparation method and application thereof

An electron beam curing, inkjet ink technology, applied in the directions of copying/marking methods, applications, inks, etc., can solve the problems of VOCs organic volatilization pollution, high product rejection rate, cumbersome process, etc., and achieve good overall airtightness and good protection. Sexual, destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In a second aspect, the present invention provides a method for preparing an electron beam curable inkjet ink as described in the first aspect, comprising the steps of:

[0047] (1) Polyurethane acrylate, dispersant, organic pigment toner, fumed silica, dodecyl methacrylate, tris(2-hydroxyethyl)isocyanurate triacrylate, tristyryl Phenol polyoxyethylene ether methacrylate is mixed, stirred evenly at high speed, and sanded with a sand mill to obtain a mixed material;

[0048] (2) After mixing the mixed material obtained in step (1) and the auxiliary agent, and using isobornyl acrylate to adjust the viscosity, an electron beam curable inkjet ink is obtained.

[0049] In the third aspect, the present invention provides an application of the electron beam inkjet ink as described in the first aspect in printing liquid crystal glass.

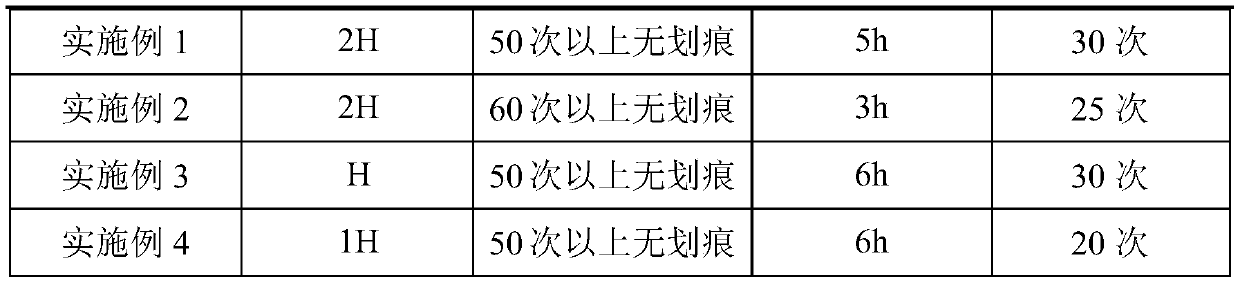

Embodiment 1

[0054] A kind of preparation method of electron beam curing inkjet ink provided in this embodiment comprises the following steps:

[0055] (1) Take the following raw materials in parts by weight: 5 parts of isocyanate IPDI monomer, 10 parts of pentaerythritol triacrylate, 0.05 part of 2,6-di-tert-butyl-4-methylphenol, dibutyltin dilaurate 0.1 part, 15 parts of polycarbonate diol (molecular weight is 2000), 10 parts of DR-E522 hyperbranched polymer, 30 parts of isobornyl acrylate, 5 parts of ethyl isocyanate acrylate (AOI), hydroxyl-terminated polybutadiene ( HTPB) 1.5 parts;

[0056] Add isocyanate IPDI monomer and pentaerythritol triacrylate to the reactor, raise the temperature to 70°C, and react for 1.5h; raise the temperature to 80°C, add 2,6-di-tert-butyl-4-methylphenol and dibutyltin dilaurate , after stirring evenly, add polycarbonate diol at one time, and react for 1.5h to obtain a semi-finished polyurethane acrylate; add DR-E522 hyperbranched polymer and isobornyl ac...

Embodiment 2

[0060] A kind of preparation method of electron beam curing inkjet ink provided in this embodiment comprises the following steps:

[0061] (1) Take the following raw materials in parts by weight: 4 parts of isocyanate IPDI monomer, 10 parts of pentaerythritol triacrylate, 0.05 part of 2,6-di-tert-butyl-4-methylphenol, dibutyltin dilaurate 0.1 part, 13 parts of polycarbonate diol (molecular weight is 2500), 10 parts of DR-E522 hyperbranched polymer, 25 parts of isobornyl acrylate, 5 parts of ethyl isocyanate acrylate (AOI), hydroxyl-terminated polybutadiene ( HTPB) 1.5 parts;

[0062] Add isocyanate IPDI monomer and pentaerythritol triacrylate to the reactor, raise the temperature to 70°C, and react for 1.5h; raise the temperature to 80°C, add 2,6-di-tert-butyl-4-methylphenol and dibutyltin dilaurate , after stirring evenly, add polycarbonate diol at one time, and react for 1.5h to obtain a semi-finished polyurethane acrylate; add DR-E522 hyperbranched polymer and isobornyl ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com