Novel efficient chemical and preparation process thereof, and application of novel efficient chemical in aquaculture wastewater treatment

A technology for aquaculture and wastewater treatment, applied in water/sewage treatment, animal husbandry wastewater treatment, biological water/sewage treatment, etc., to achieve the effects of reducing COD, promoting microbial reproduction, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of described modified coconut shell powder, comprises the following steps:

[0029] (1) adding the coconut shell powder to the sulfuric acid with a mass concentration of 52% for soaking treatment for 3.5 hours, removing and washing with clear water for 3 times, and then drying;

[0030] (2) adding the dried coconut shell powder into a muffle furnace, and calcining at a temperature of 300-440° C. for 1.5 hours to obtain calcined coconut shell powder;

[0031] (3) Add the calcined coconut shell powder to a mixed solution containing 4.2% sodium alginate and 3.5% itaconic acid at a concentration of 4.2%, ultrasonically treat it for 2 hours at an ultrasonic frequency of 26 kHz, and filter to obtain a filter residue, which is then dried , to obtain modified coconut shell powder;

[0032] The composite bacterial agent is a mixture of Rhodopseudomonas palustris and plant Lactobacillus in a mass ratio of 2:1;

[0033] The preparation method of the new hi...

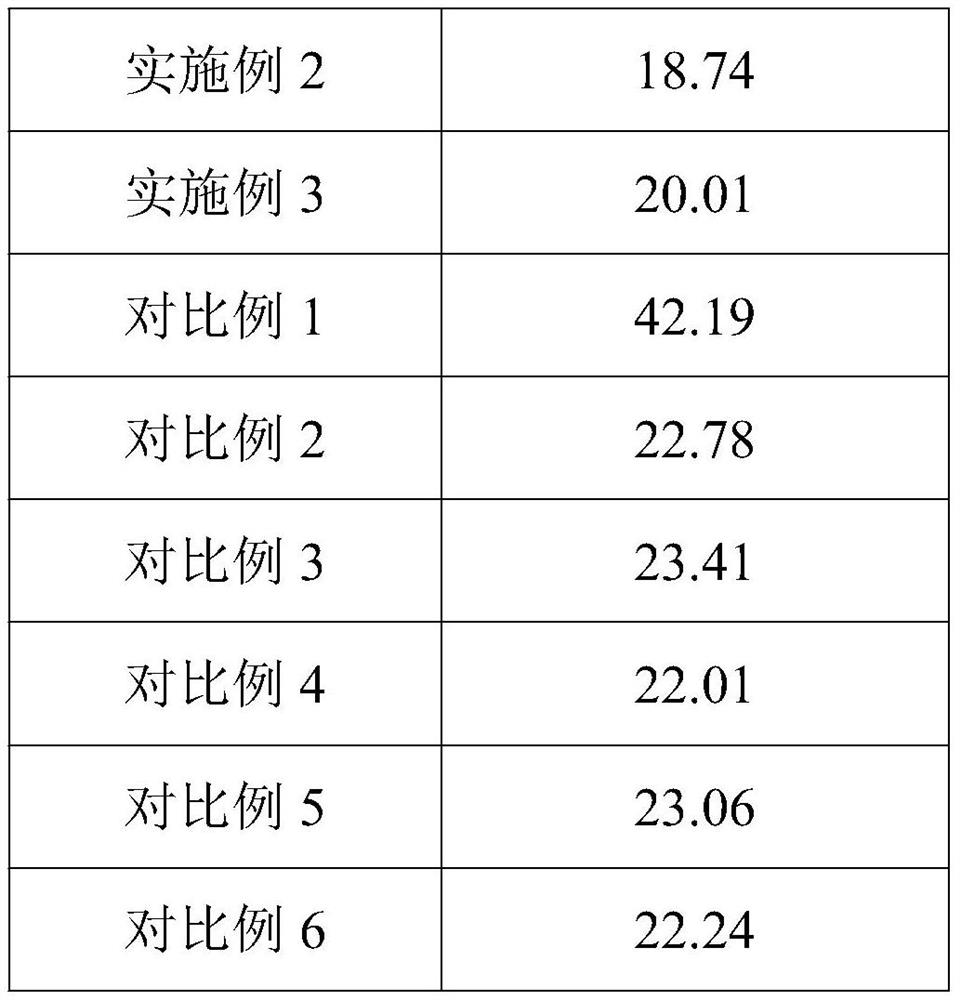

Embodiment 1

[0043] A new type of high-efficiency medicament, in parts by weight, including the following raw materials: 75 parts of modified coconut shell powder, 42 parts of decomposed soybean meal, 9 parts of compound bacterial agent, 3.3 parts of astaxanthin, 6 parts of diatomaceous earth, humic acid 4 parts sodium, 0.7 parts sodium lignosulfonate, 0.3 parts soybean oligopeptide powder, 0.6 parts lauryl methacrylate;

[0044] The preparation method of described modified coconut shell powder, comprises the following steps:

[0045] (1) adding the coconut shell powder to the sulfuric acid with a mass concentration of 52% for soaking treatment for 3.5 hours, removing and washing with clear water for 3 times, and then drying;

[0046] (2) adding the dried coconut shell powder into a muffle furnace, and calcining at a temperature of 300-440° C. for 1.5 hours to obtain calcined coconut shell powder;

[0047](3) Add the calcined coconut shell powder to a mixed solution containing 4.2% sodium...

Embodiment 2

[0058] A new type of high-efficiency medicament, in parts by weight, including the following raw materials: 86 parts of modified coconut shell powder, 45 parts of decomposed soybean meal, 9.4 parts of composite bacterial agent, 3.8 parts of astaxanthin, 8 parts of diatomaceous earth, humic acid 5 parts of sodium, 0.9 parts of sodium lignosulfonate, 0.4 parts of soybean oligopeptide powder, 0.7 parts of lauryl methacrylate;

[0059] The preparation method of described modified coconut shell powder, comprises the following steps:

[0060] (1) adding the coconut shell powder to the sulfuric acid with a mass concentration of 52% for soaking treatment for 3.5 hours, removing and washing with clear water for 3 times, and then drying;

[0061] (2) adding the dried coconut shell powder into a muffle furnace, and calcining at a temperature of 300-440° C. for 1.5 hours to obtain calcined coconut shell powder;

[0062] (3) Add the calcined coconut shell powder to a mixed solution contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com