Process for manufacturing equipment for treating pollution water body

A technology of treatment equipment and manufacturing method, which is applied in the directions of light water/sewage treatment, oxidized water/sewage treatment, energy waste water treatment, etc., and can solve the problems of weak industrial waste water treatment capacity, difficulty in reducing chemical oxygen consumption, and undiscovered problems. , to achieve the effect of reliable equipment, convenient operation and reasonable equipment design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

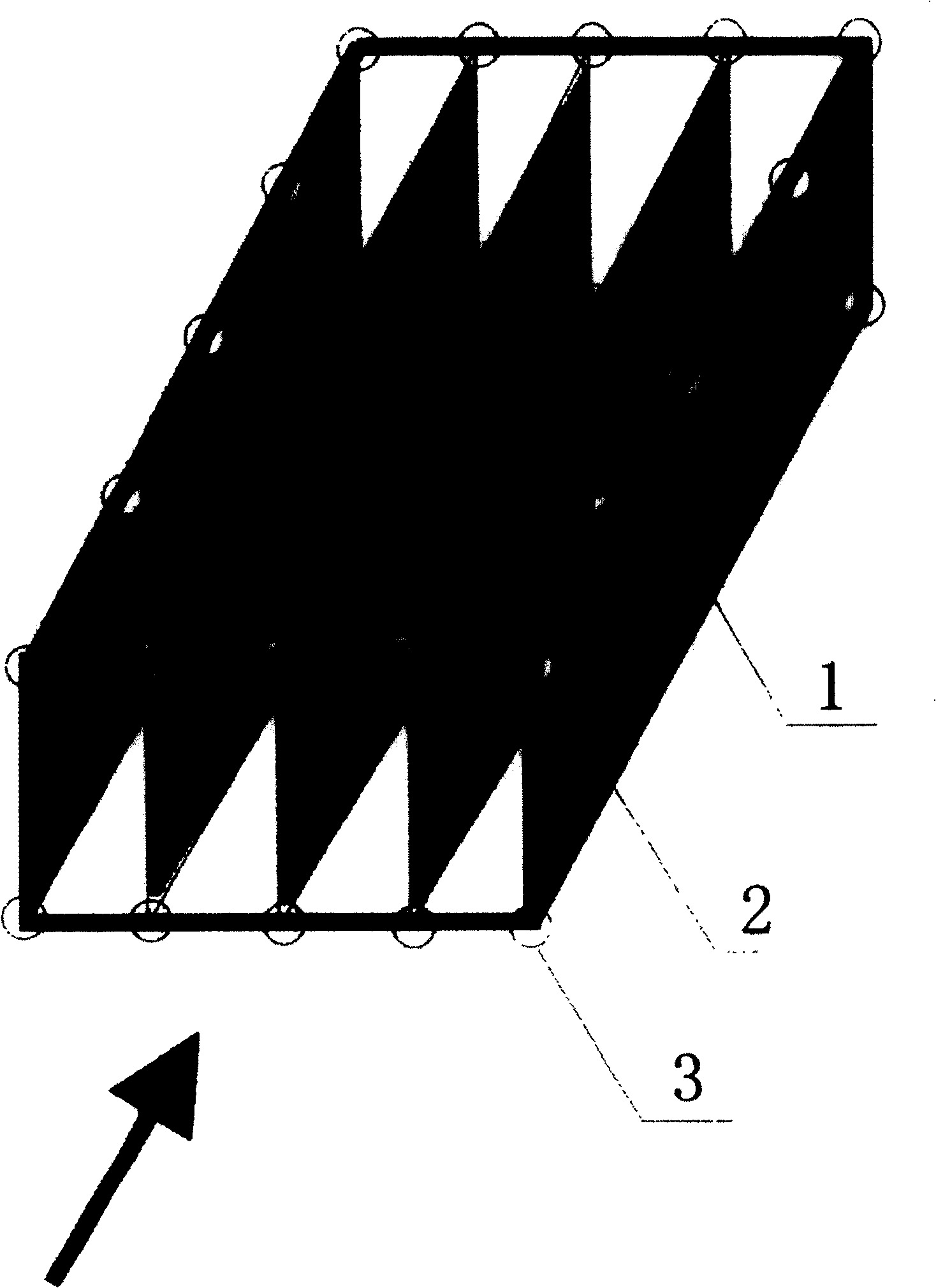

[0012] The equipment prepared by the invention is mainly used for treating organic sewage in polluted rivers and lakes, and the subsequent treatment process of industrial organic wastewater. During the processing, strong sunlight is required, which is beneficial for the equipment to exert its photolysis function. Provide following embodiment in conjunction with content of the present invention:

[0013] First, 10 kg of anatase-type TiO2 nanoparticle slurry was prepared by conventional sol-gel method, and then Ag / TiO2 was prepared by photochemical deposition 2 catalyst of light. Nine pieces of glass fiber cloth 1 with a length of 3 meters and a width of 0.5 meters were immersed in the modified titanium dioxide nanoparticles Ag / TiO 2 Take it out after 3 hours in the slurry, and bake it in a muffle furnace at a temperature of about 400° C. for 3 hours. Be that the plastic pipe 2 lap of 80mm grows 3 meters, wide 2 meters, the cuboid frame of height 0.5 meter with outer diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com