Patents

Literature

31 results about "Photochemical deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

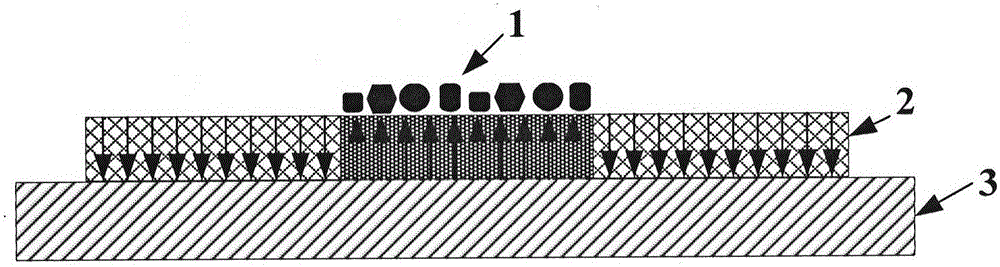

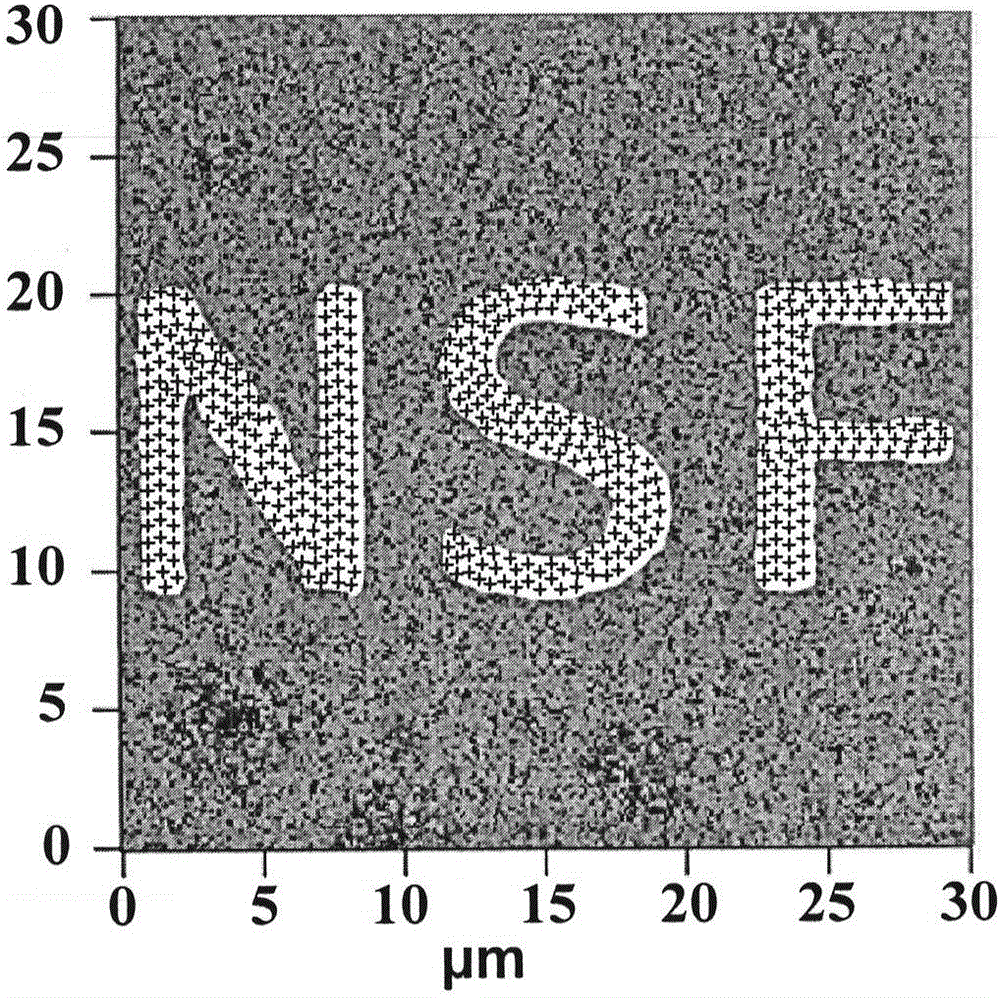

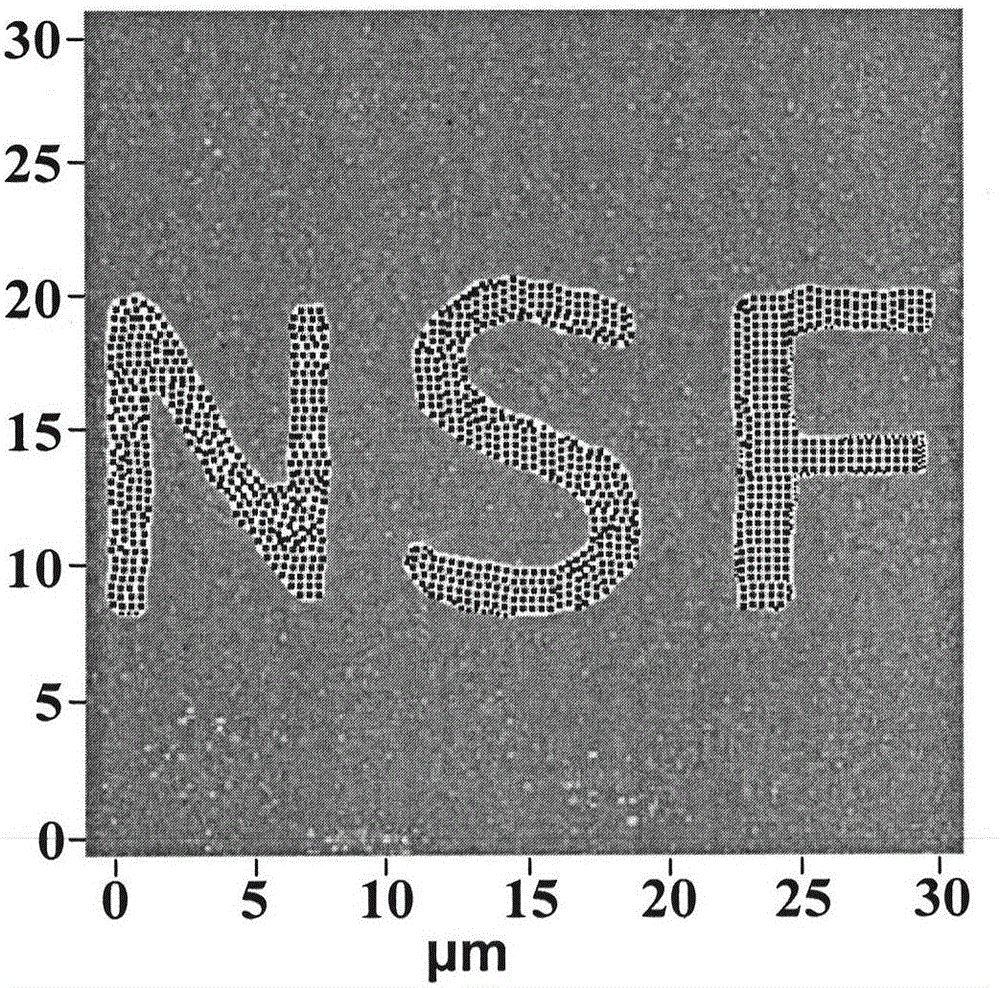

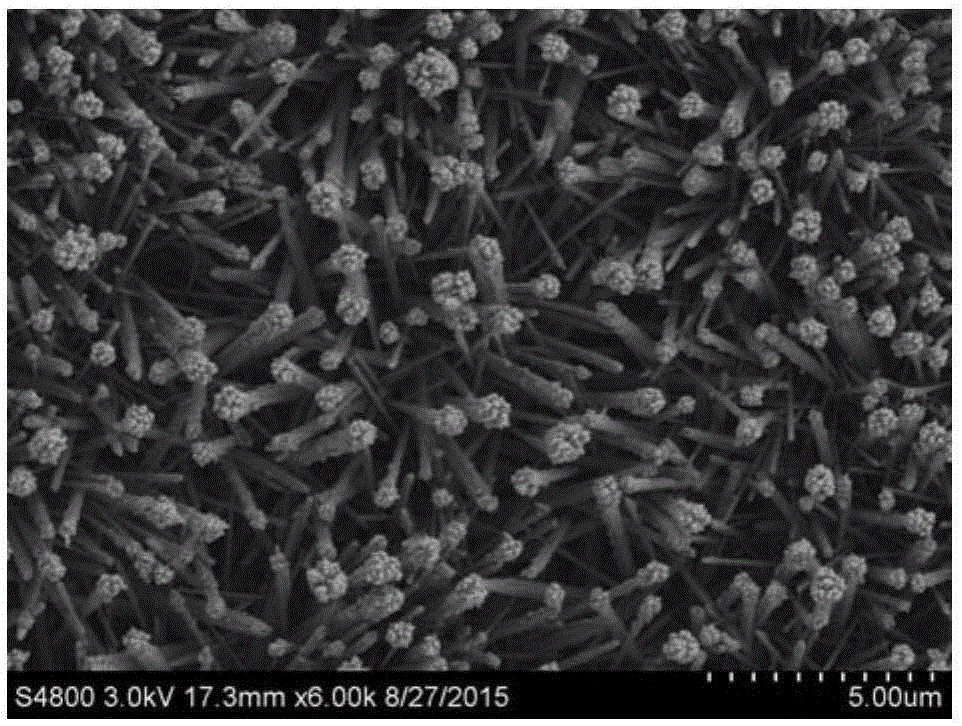

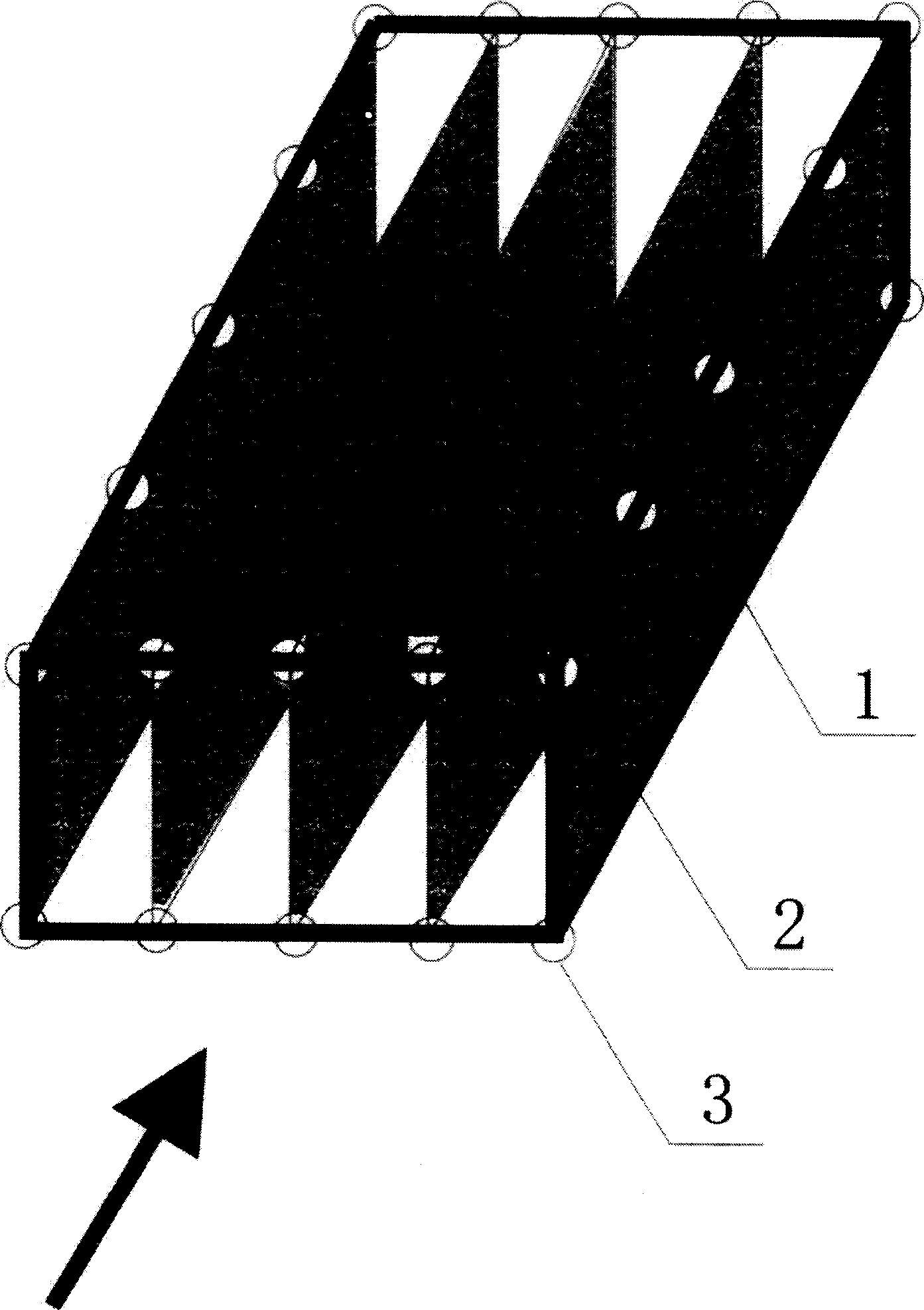

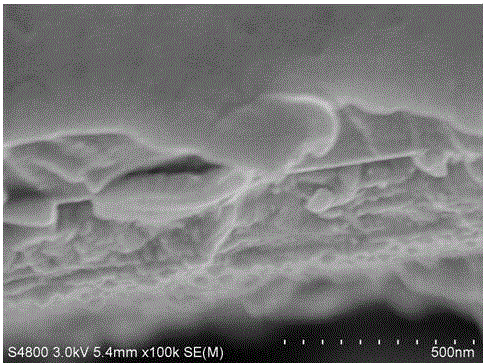

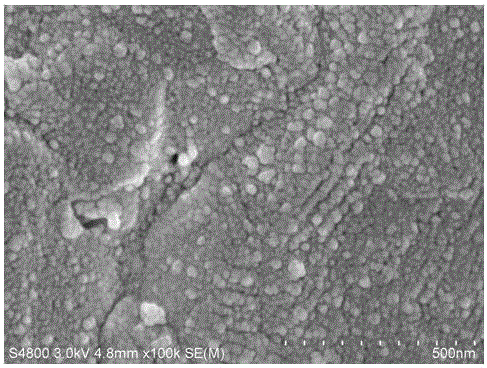

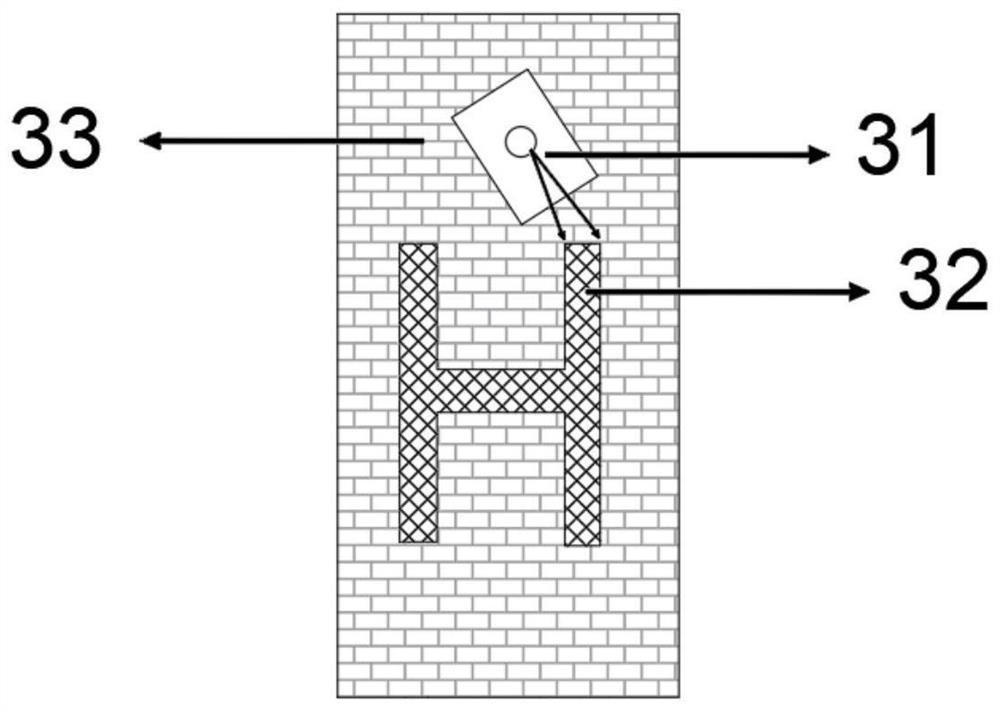

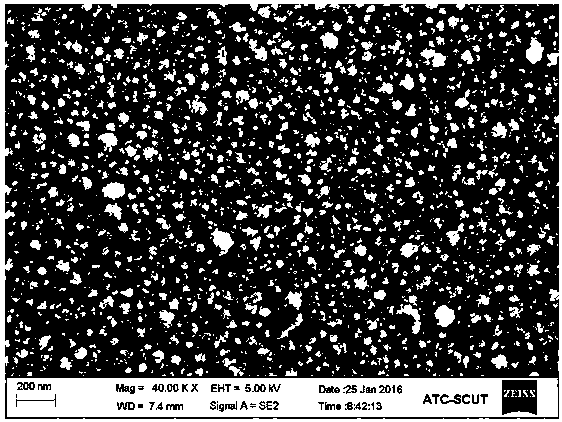

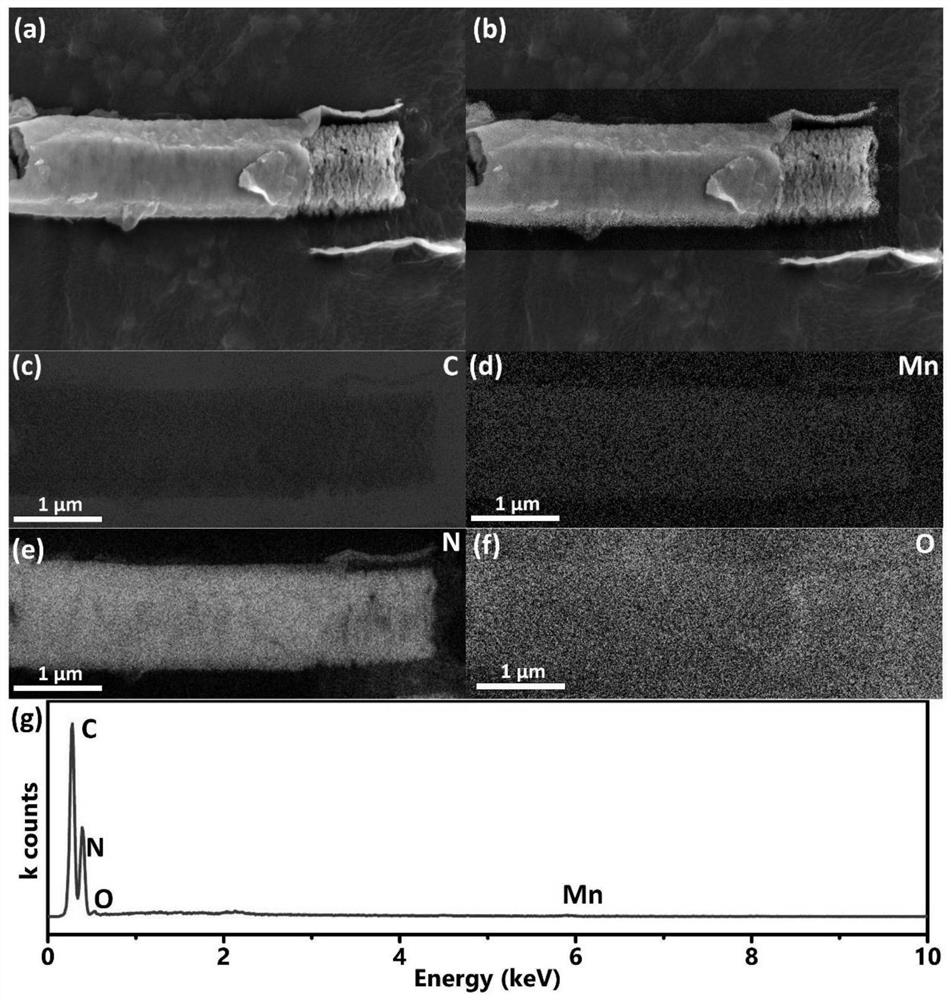

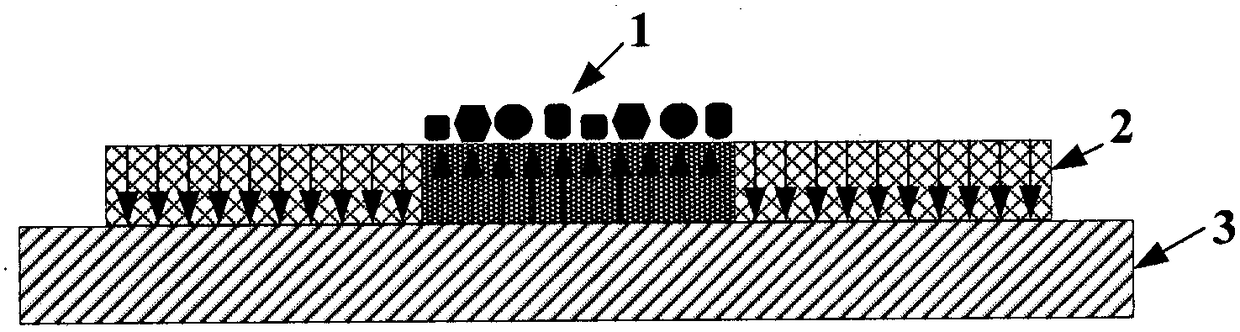

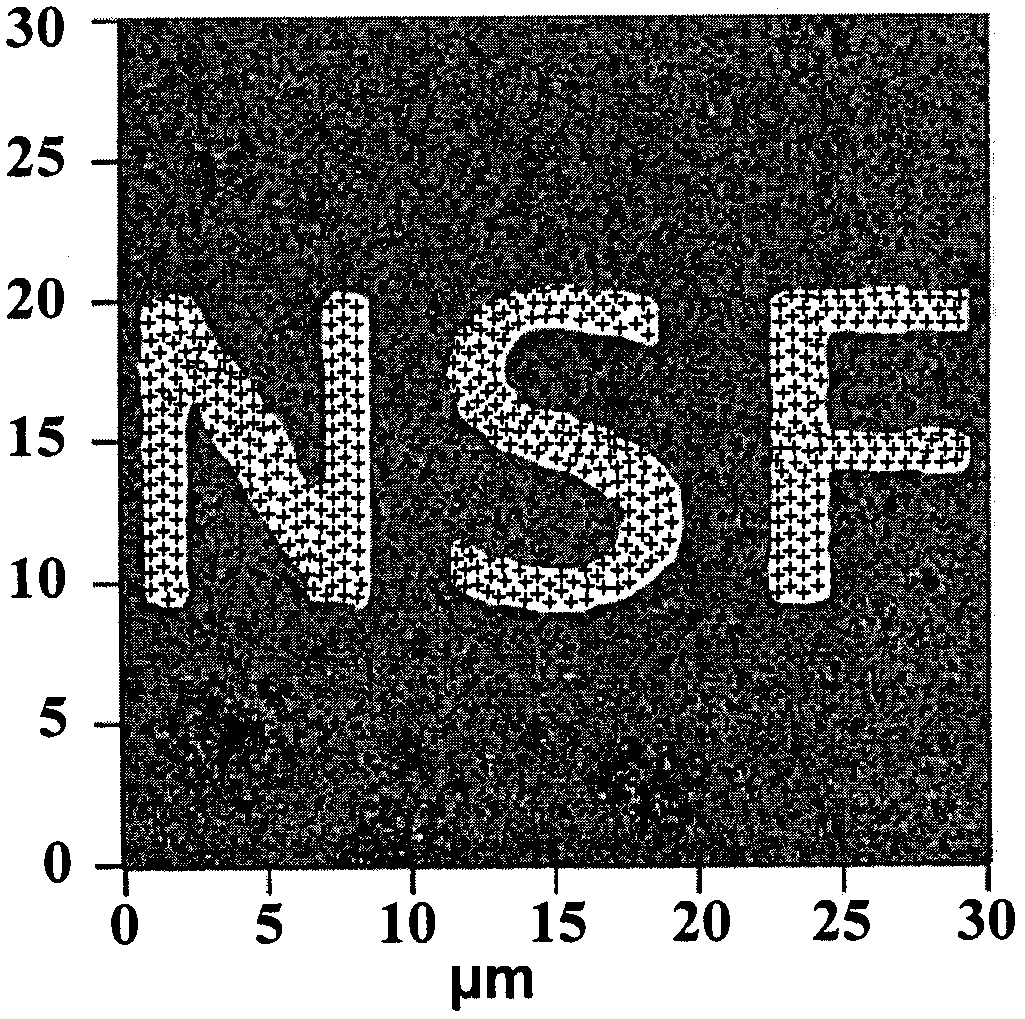

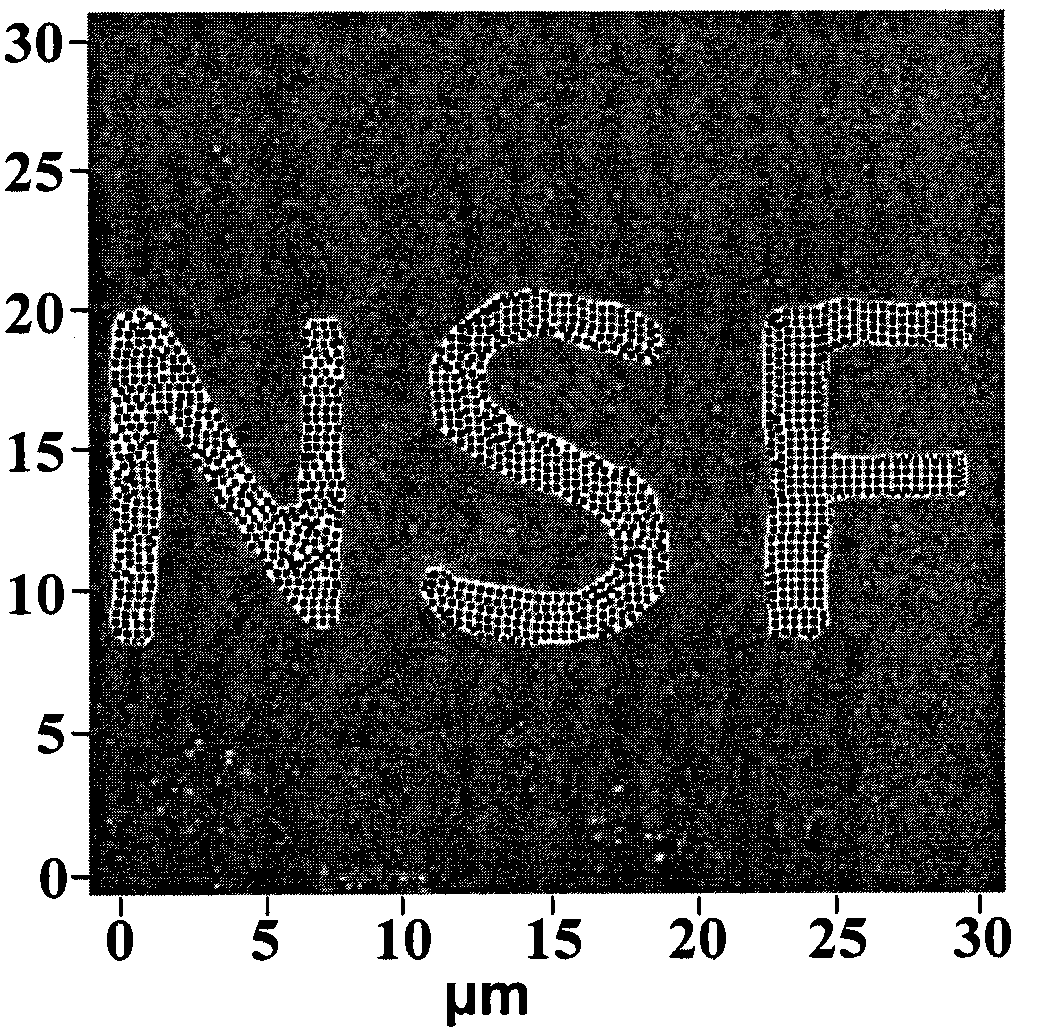

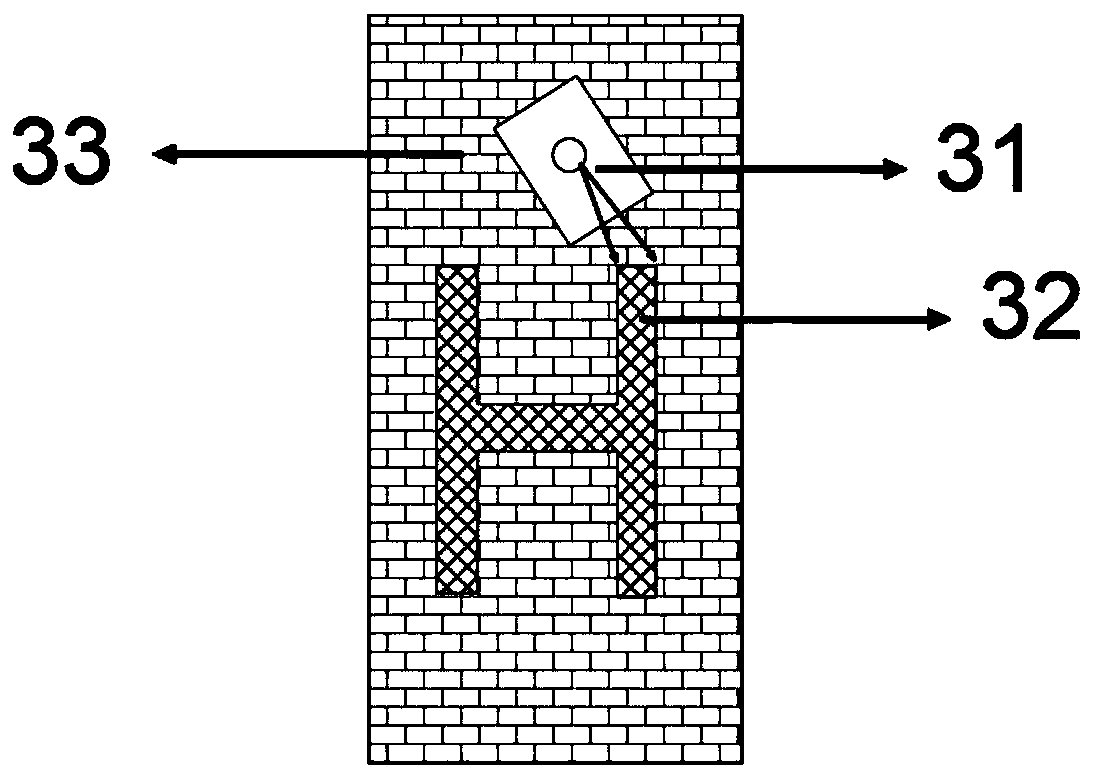

Micro-nano magnetoelectric coupler based on ferroelectric film and self-assembly magnetic nanometer particle structure

InactiveCN105789432ASimple production processSuitable for controllable integrated productionSolid-state devicesGalvano-magnetic device detailsMicro nanoMagnetite Nanoparticles

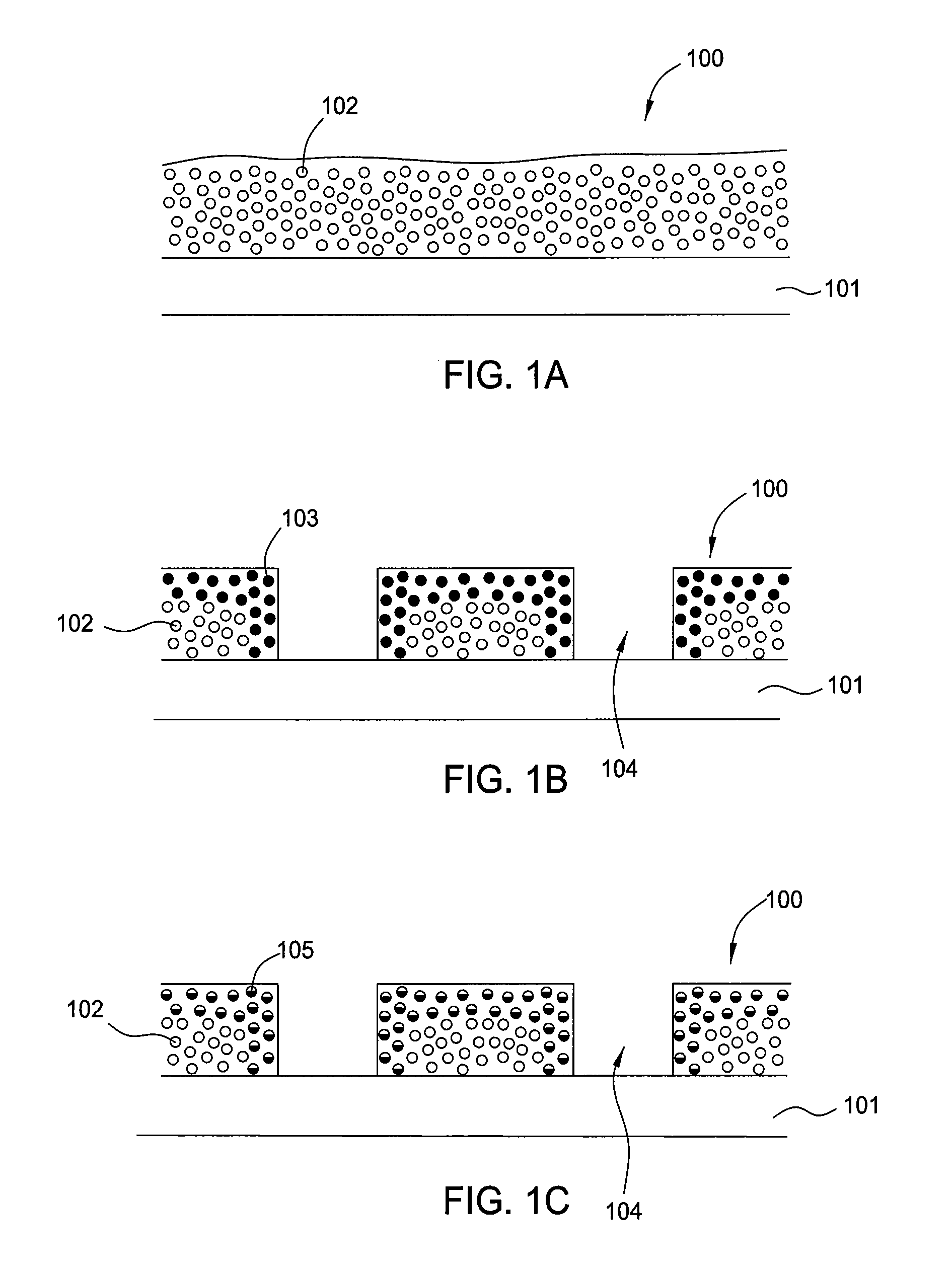

In order to solve the problem that high-performance micro-nano magnetoelectric coupler can not be easily manufactured under control, the invention provides a magnetoelectric coupler with a ferroelectric film and a self-assembly magnetic nanometer particle structure. The magnetoelectric coupler is manufactured in such a manner that the ferroelectric film is subjected to graphical +Z and -Z ferroelectric domain processing through piezoresponse force microscopy technology, and self-assembly magnetic metallic nanometer particles are polarized on the ferroelectric domain surface through photochemical sedimentation. The coupler comprises a ferroelectric film layer, a conductive substrate supporting the ferroelectric film, and a self-assembled magnetic nanometer particle structure on the ferroelectric film layer. micro-nano-level PZT ferroelectric domain with polarized distribution according to any graphs is processed through piezoresponse force microscopy technology, and the magnetic metallic nanometer particle structure is self-assembled through photochemical sedimentation. The production technology is simple, and the integrated production of micro-nano magnetoelectric couplers is facilitated.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

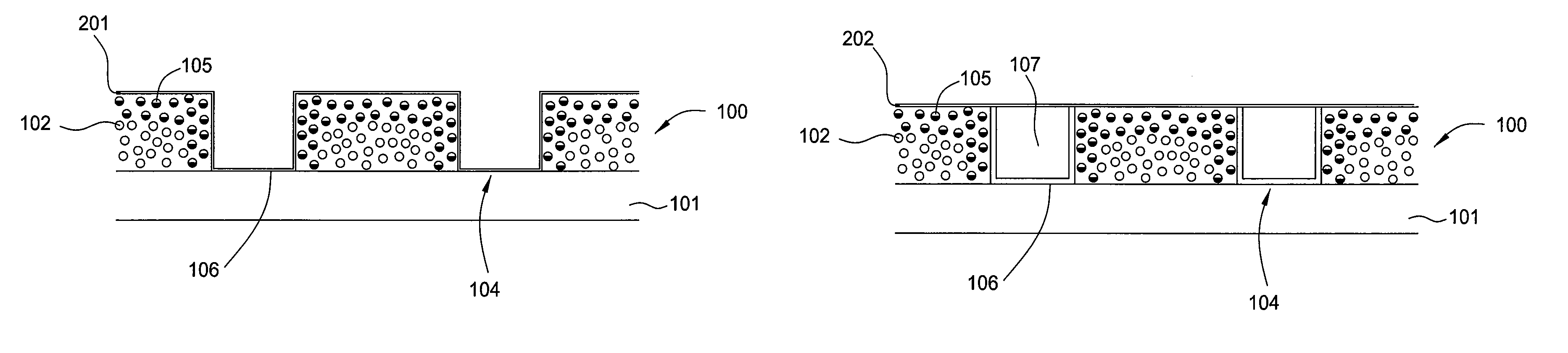

Dielectric recovery of plasma damaged low-k films by UV-assisted photochemical deposition

Methods for the repair of damaged low k films are provided. Damage to the low k films occurs during processing of the film such as during etching, ashing, and planarization. The processing of the low k film causes water to store in the pores of the film and further causes hydrophilic compounds to form in the low k film structure. Repair processes incorporating ultraviolet (UV) radiation and carbon-containing compounds remove the water from the pores and further remove the hydrophilic compounds from the low k film structure.

Owner:APPLIED MATERIALS INC

Preparation method for Au-Ag co-modified N-doped ZnO nanorods and application of ZnO nanorods to hydrogen production through photo-electrochemical hydrolysis

InactiveCN105347387AImprove stabilityImprove photoelectric conversion efficiencyPhysical/chemical process catalystsZinc oxides/hydroxidesSynthesis methodsTwo step

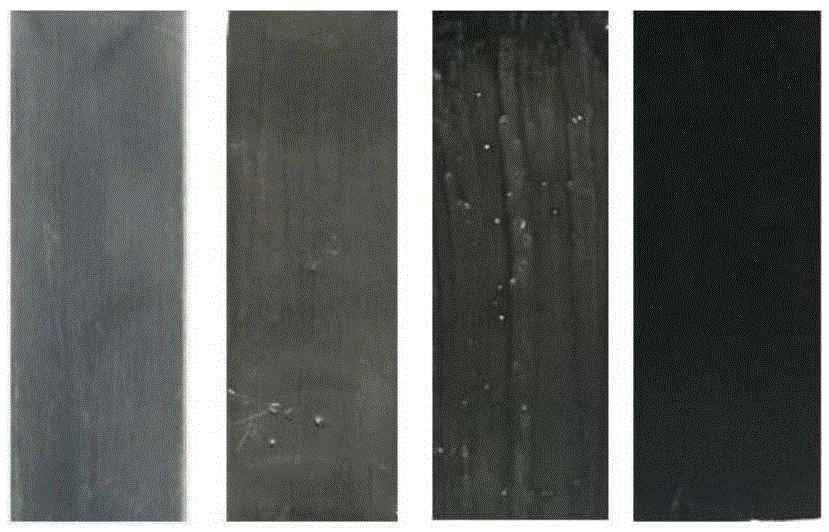

The invention discloses a preparation method for Au-Ag co-modified N-doped ZnO nanorods, the ZnO nanorods obtained according to the preparation method, and application of the ZnO nanorods. According to a photochemical deposition method, a simple and environment-friendly in-situ synthesis method for the ZnO nanorods is formed and comprises the following two steps: electrons generated on the ZnO nanorods serve as a reducing agent to react with Ag<+> ions in a solution, so that in-situ deposition of Ag nano-particles on the surfaces of the ZnO nanorods is realized; then, the reaction product is directly put in a HAuCl4 solution, and electrons generated on the Ag nano-particles serve as a reducing agent to react with AuCl4<-> ions in the HAuCl4 solution. No any additional reducing reagents and organic modifiers are needed in the two steps, so that the reaction processes are environmentally friendly; a clean contact interface is beneficial to rapid separation and transfer of photo-generated electrons, and improvement in the photo-electrochemical activity of a material.

Owner:ANHUI UNIVERSITY

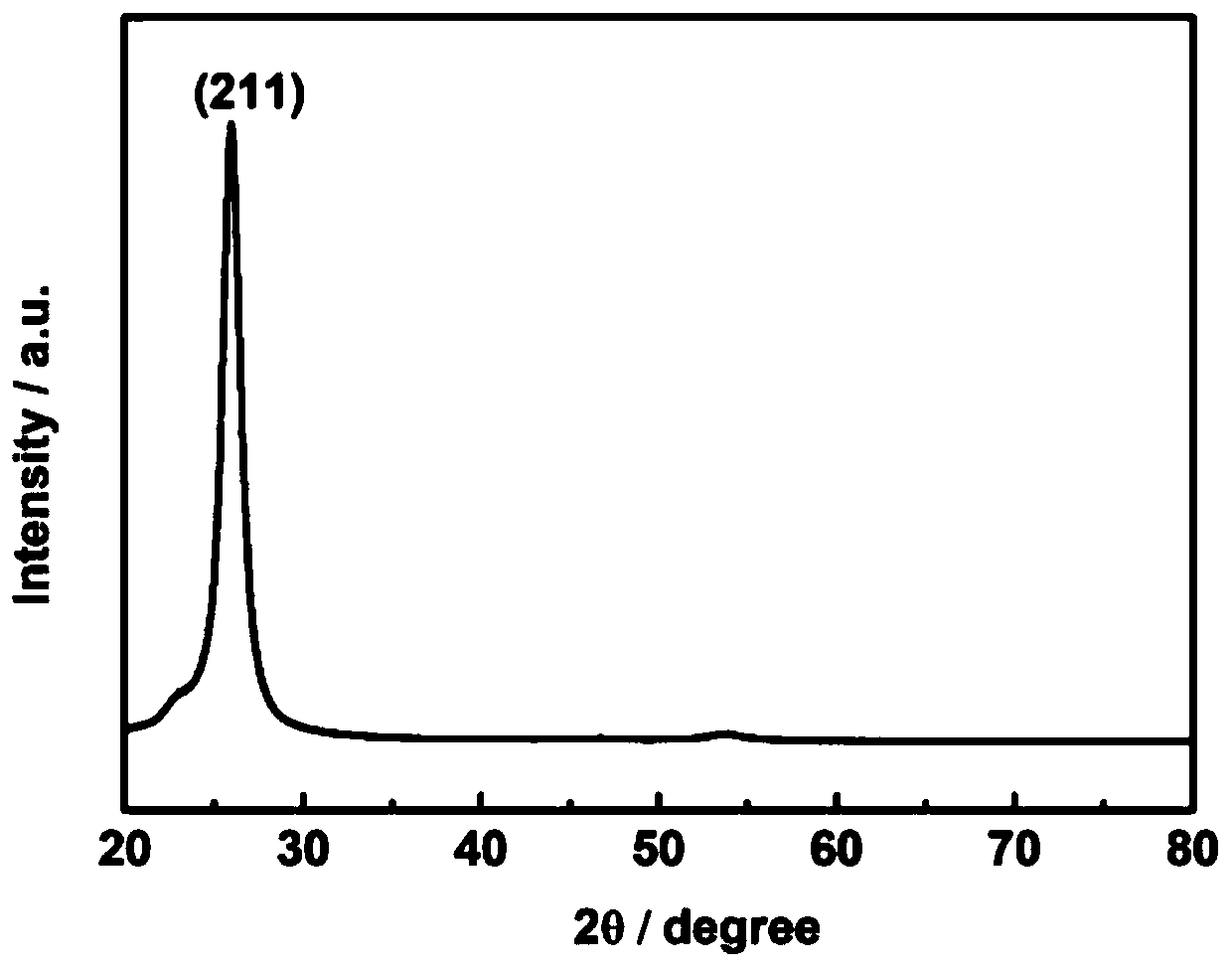

Method for preparing noble-metal-supported p-NiO/n-NiFe2O4 composite semiconductor photocatalyst

InactiveCN102389809ASmall particle sizeImprove photocatalytic efficiencyCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSolvent

The invention discloses a method for preparing a noble-metal-supported p-NiO / n-NiFe2O4 composite semiconductor photocatalyst. The method comprises the following steps of: 1, sequentially performing microwave reaction on nickel salt, iron salt, citric acid, alkali and deionized water which are taken as raw materials, performing ultrasonic dispersion, heating and reacting, washing, performing ultrasonic dispersion, filtering, drying, roasting and grinding to obtain NiFe2O4 solid powder; 2, sequentially reacting the NiFe2O4 solid powder, nickel salt, alkali and deionized water which are taken asraw materials, performing ultrasonic dispersion, dehydrating under reduced pressure, performing heat treatment, washing, performing ultrasonic dispersion, filtering, drying, roasting and grinding to obtain p-NiO / n-NiFe2O4 solid powder; and 3, sequentially stirring the p-NiO / n-NiFe2O4 solid powder, a noble metal compound, ethanol and deionized water which are taken as raw materials and dissolving,performing ultrasonic dispersion, performing photochemical deposition reaction, removing a solvent under reduced pressure, performing heat treatment, washing, filtering, drying, roasting and grindingto obtain the noble-metal-supported p-NiO / n-NiFe2O4 composite semiconductor photocatalyst.

Owner:NANJING UNIV OF TECH

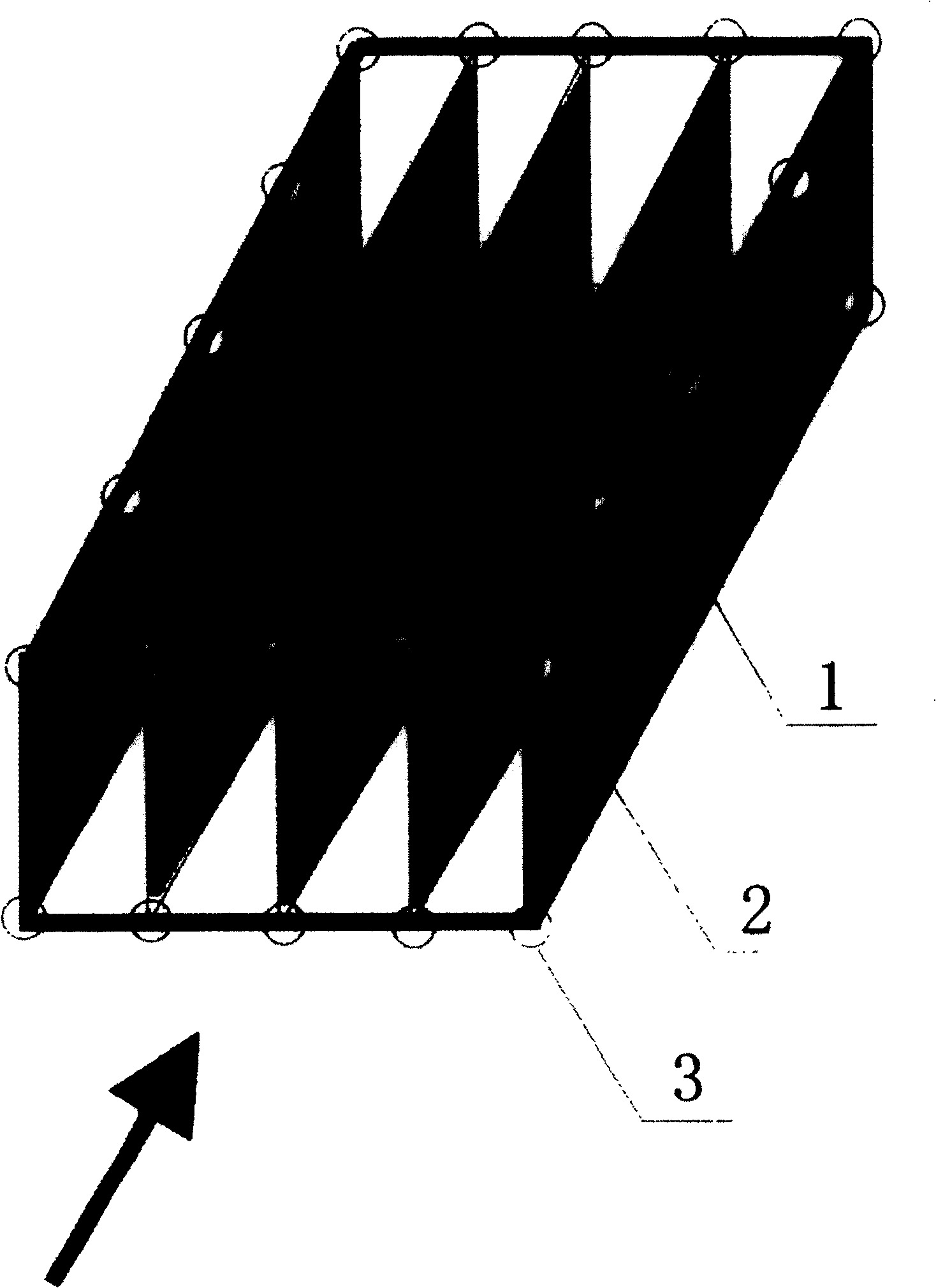

Process for mfg. equipment for treating pollution water body

InactiveCN1792865AImprove photocatalytic abilityThorough decomposition abilityCatalyst carriersWater/sewage treatment by irradiationPolymer scienceSlurry

A process for preparing the sewage treating apparatus includes such steps as preparing the slurry of anatase-type TiO2 nano-particle by sol-gel method, preparing photocatalyst Ag / TiO2 by photochemical deposition method, adding TiO2 to AgNO3 solution, adsorbing while stirring, radiating by low-pressure Hg lamp, distilled water washing to remove excessive Ag ions, braiding glass fibers to obtain needed shape, immersing it in modified TiO2 nano-particles slurry, sintering and installing it to the frame made of plastic tube.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

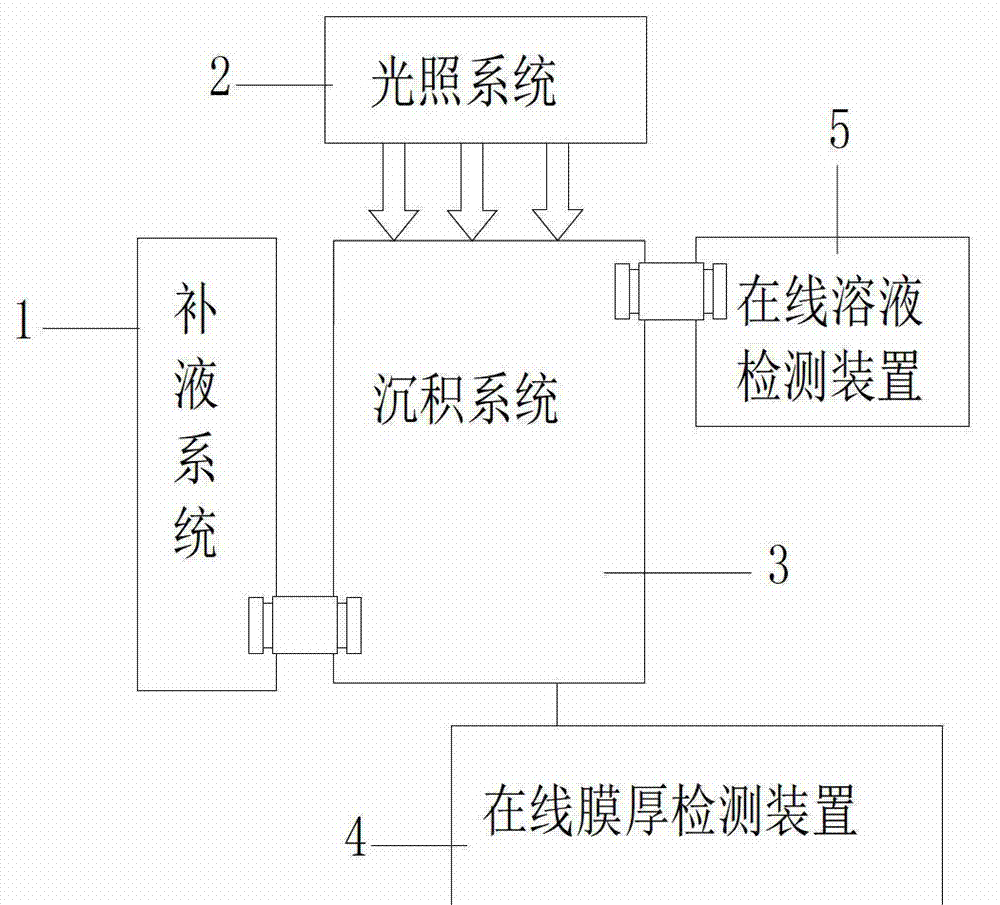

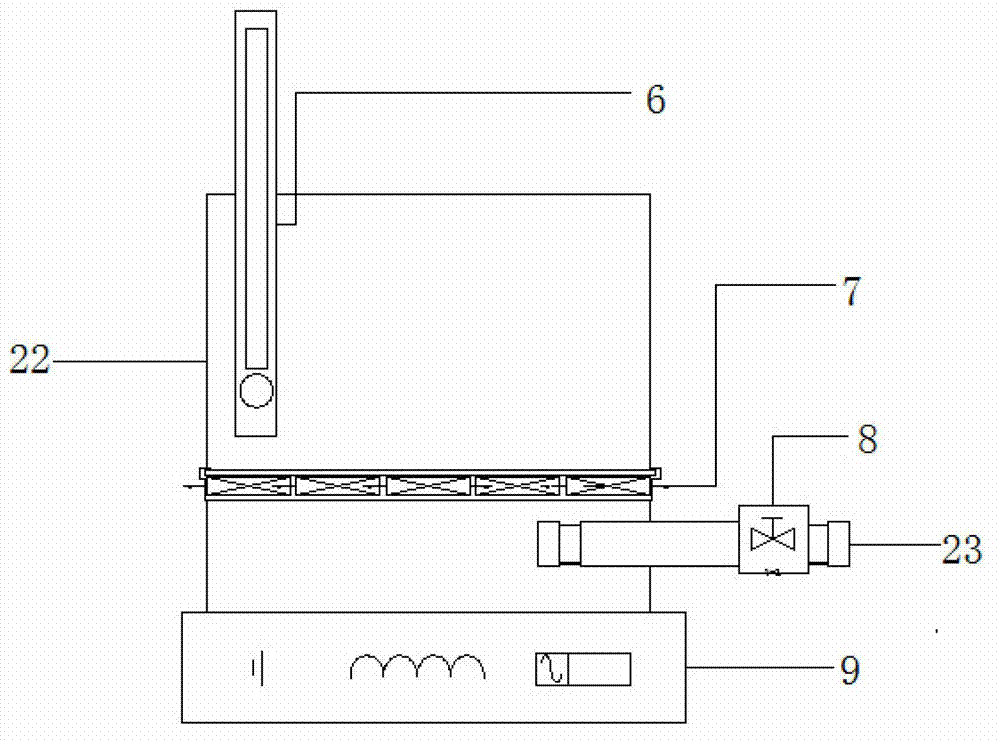

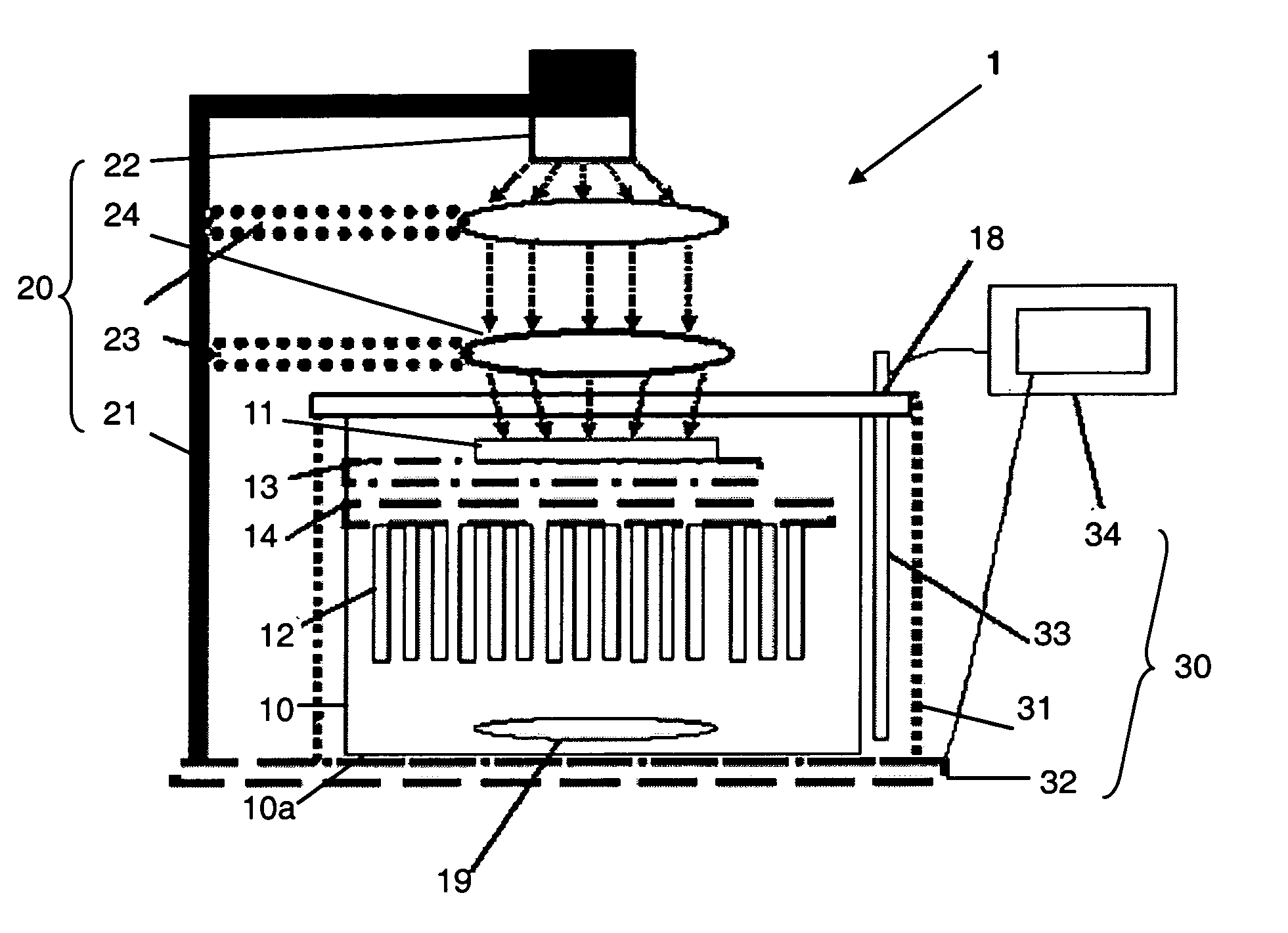

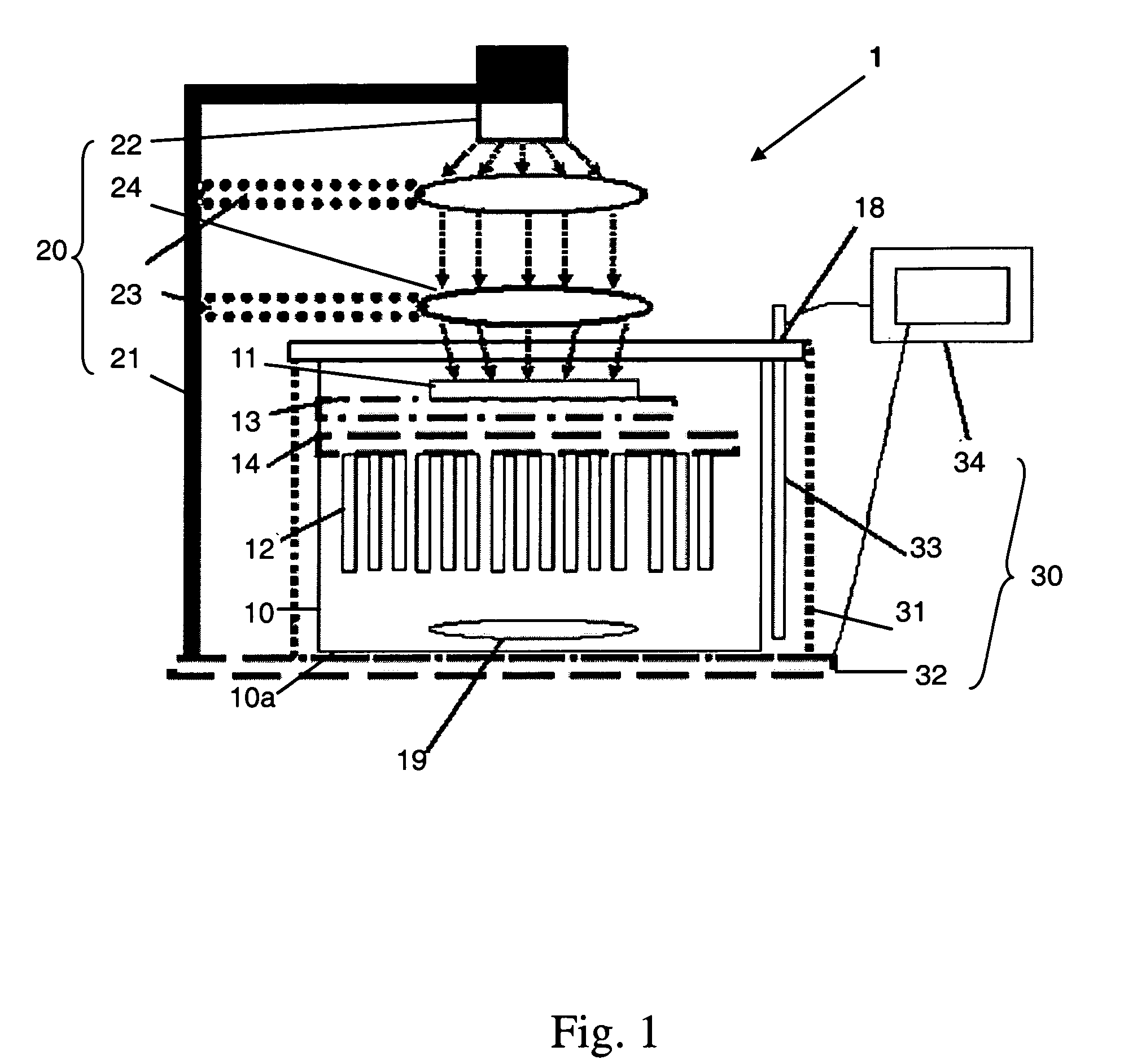

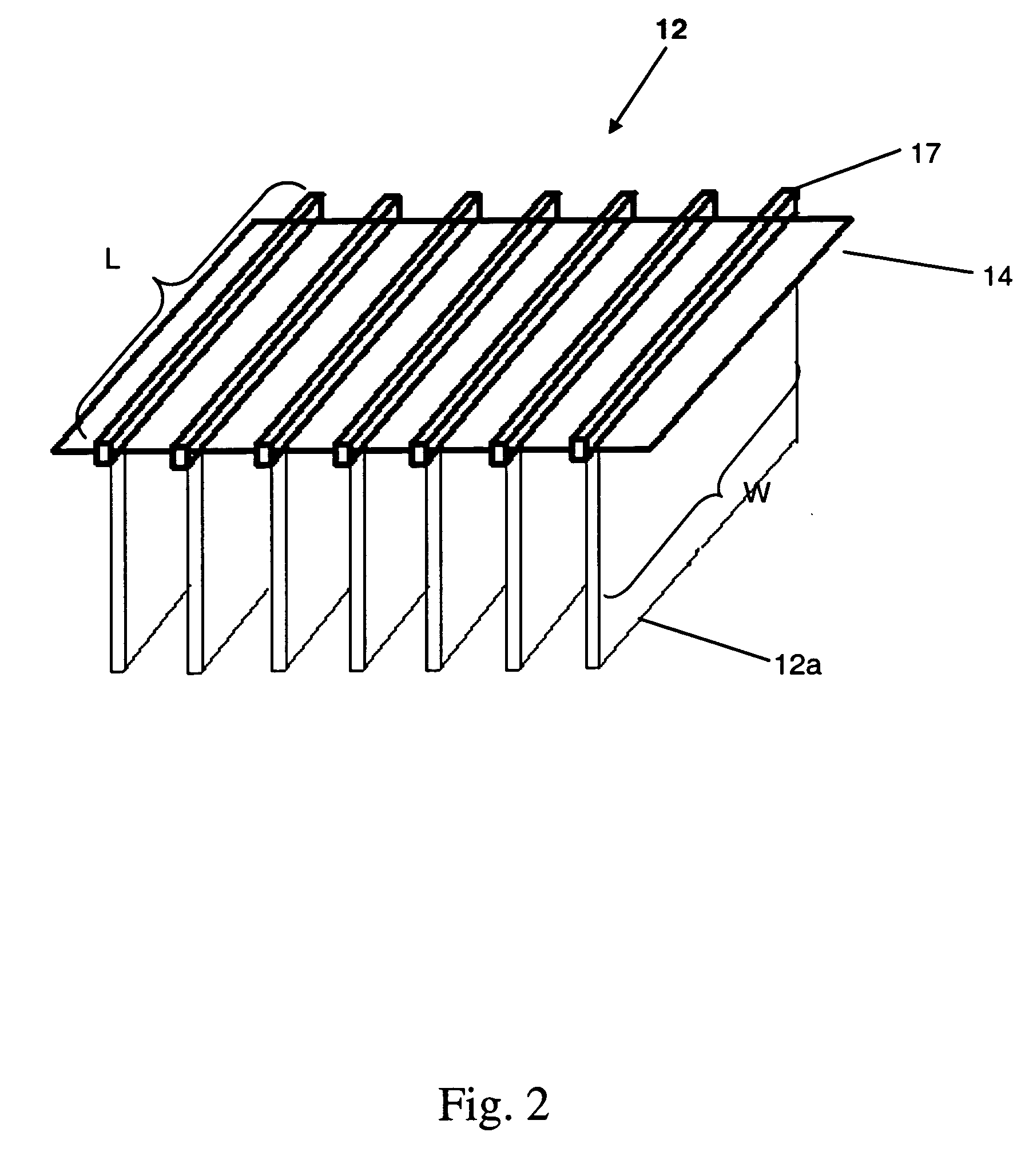

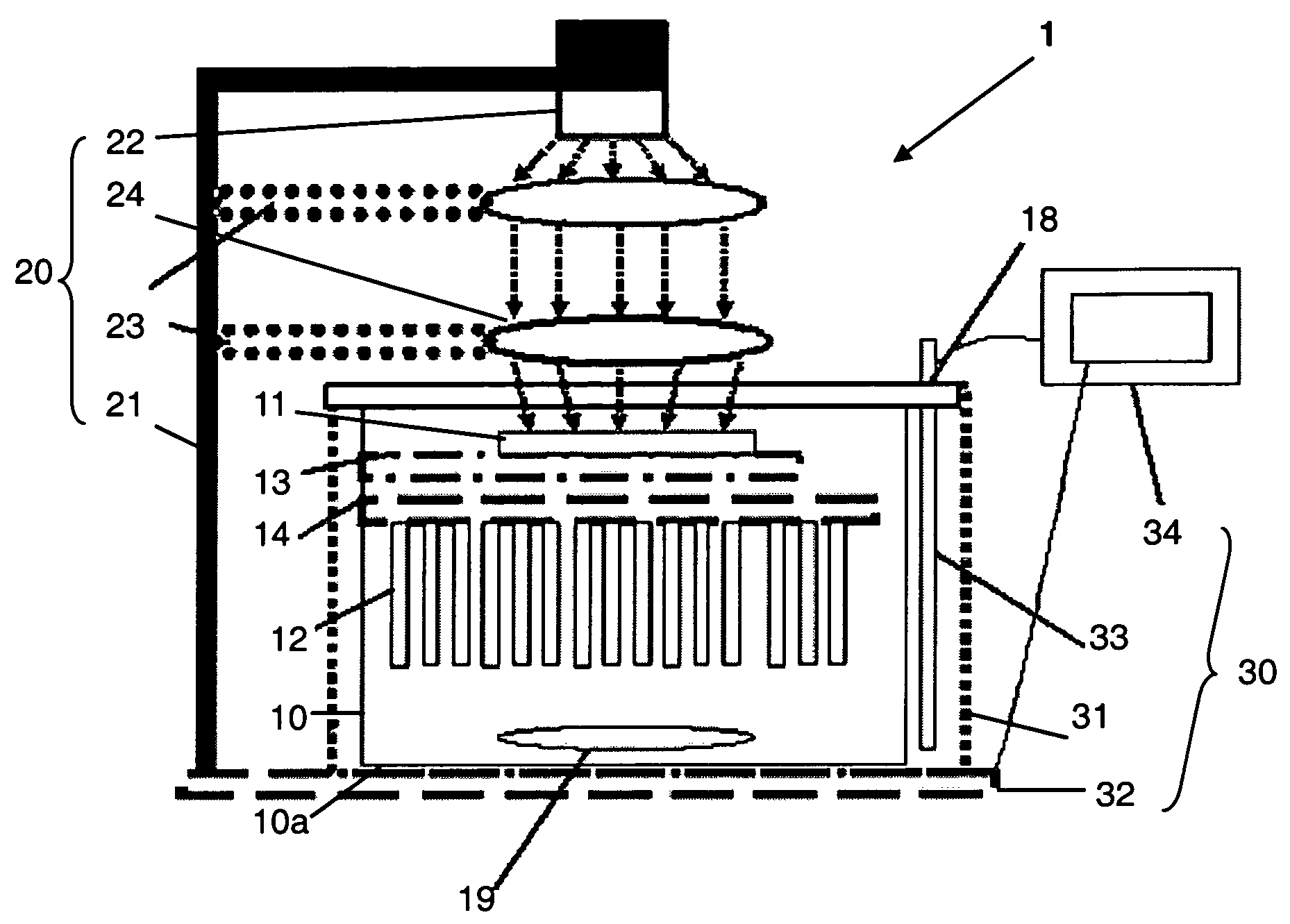

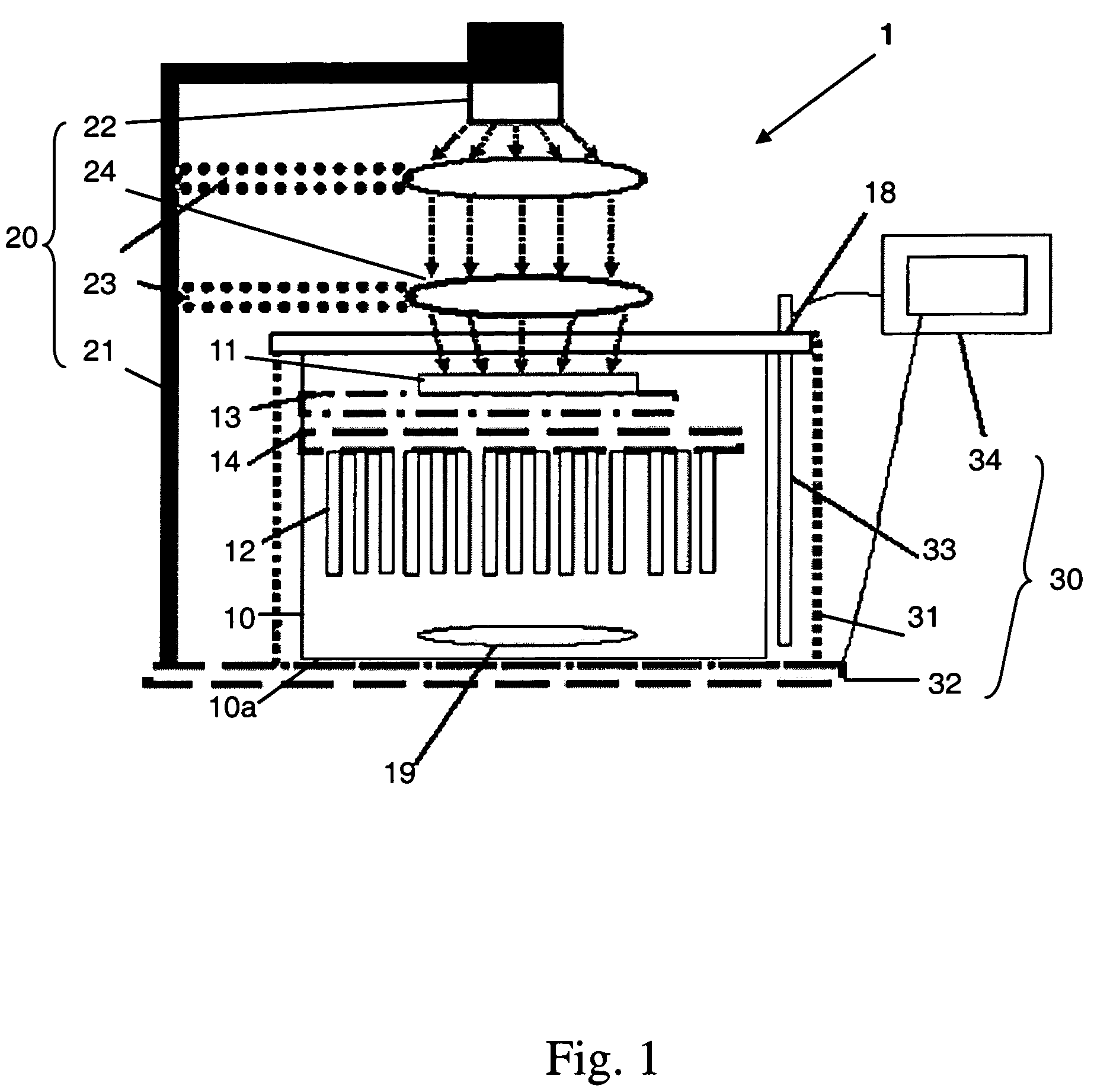

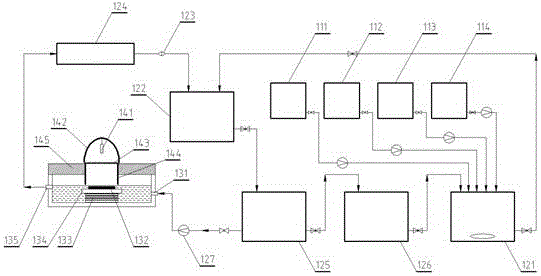

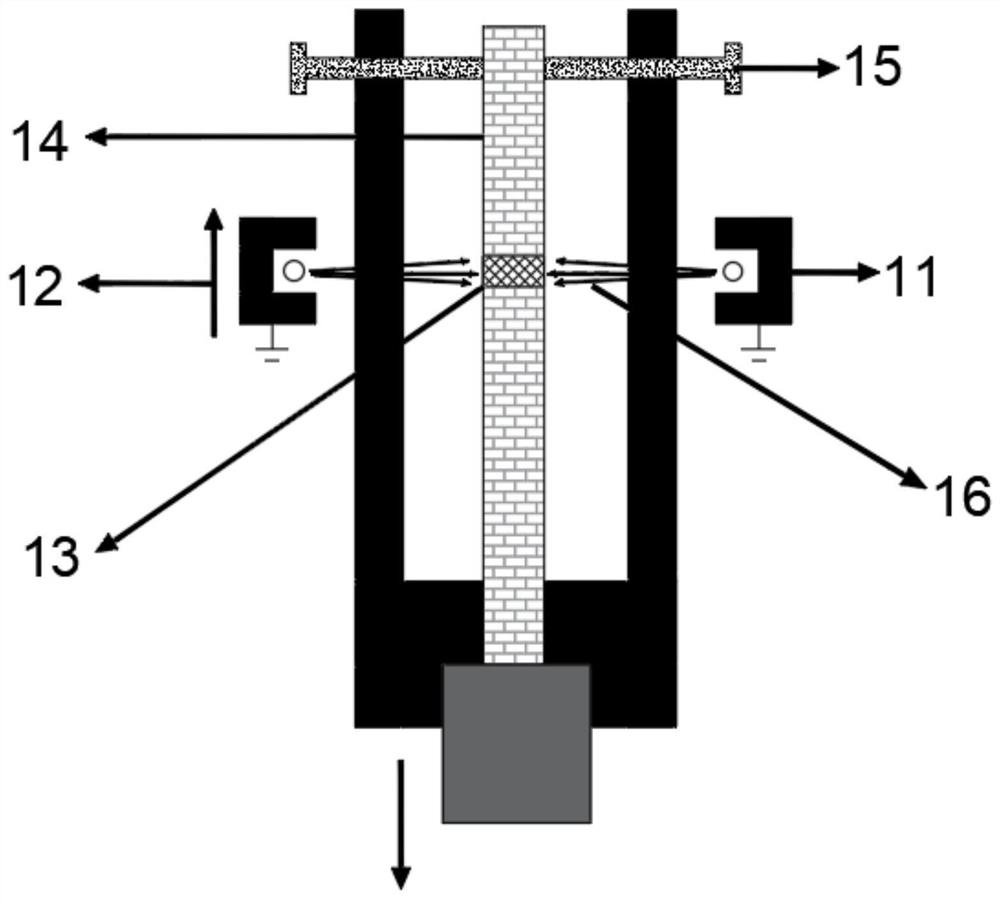

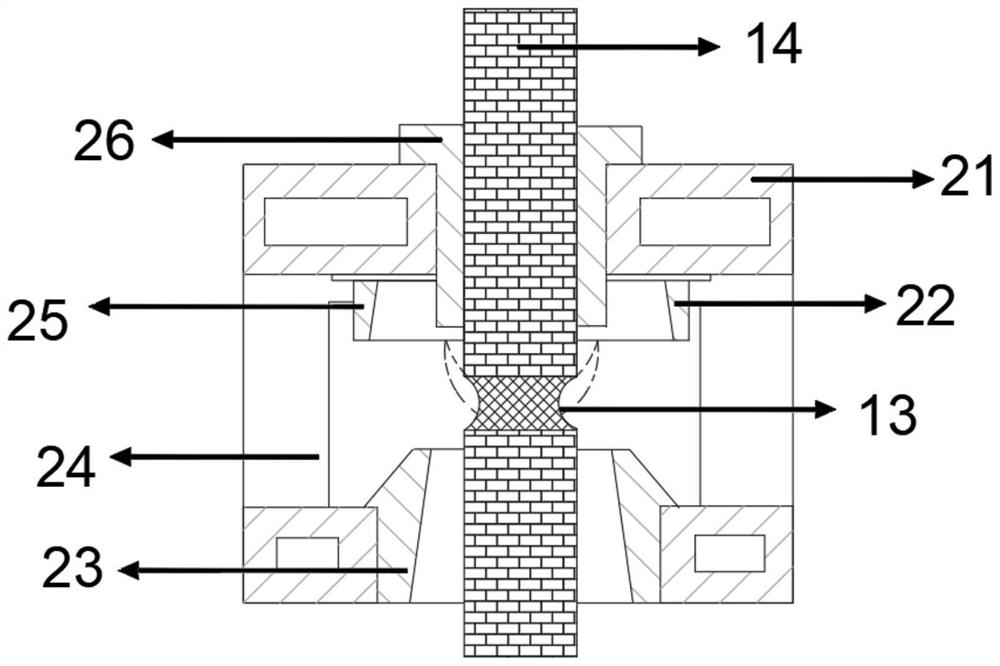

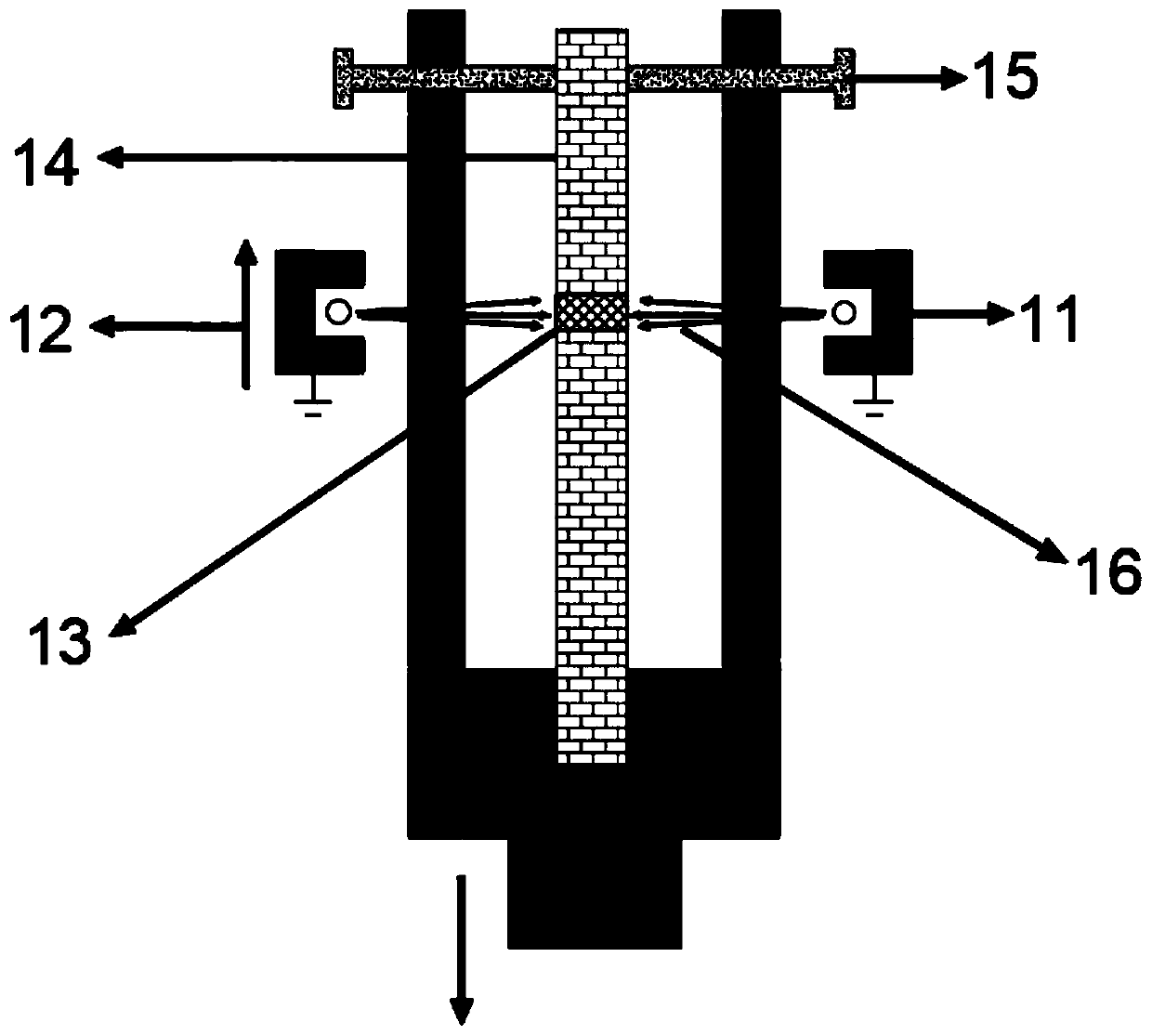

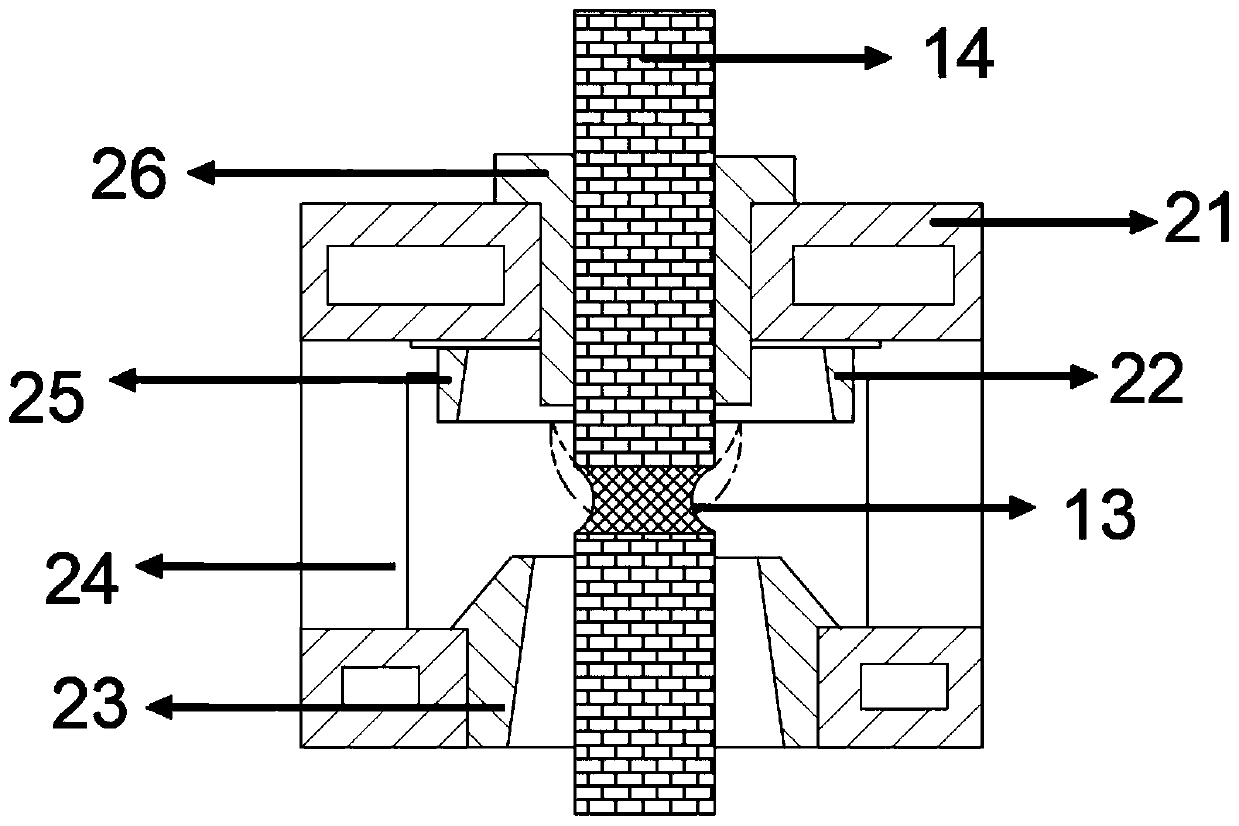

Photochemical deposition device for solar cells

ActiveCN102817013AGuaranteed temperatureGuaranteed purityFinal product manufactureChemical vapor deposition coatingEngineeringTemperature monitoring

The invention relates to a photochemical deposition device for solar cells, which comprises a solution supplementing system and a deposition system, wherein the liquid supplementing system comprises a liquid supplementing chamber for containing a reaction solution; the bottom in the liquid supplementing chamber is provided with a first heater, and the upper part is provided with a first on-line temperature monitoring device; the liquid supplementing chamber is provided with a liquid output pipeline for delivering the liquid to the deposition system; a filter unit is arranged above the liquid output pipeline; the liquid output pipeline is provided with a liquid flowmeter; the deposition system comprises a deposition reaction chamber; the bottom of the deposition reaction chamber is provided with a second heater, a bubbling device, a time controller and a circulating device; a vacuum adsorption device for fixing a silicon wafer into the deposition reaction chamber is installed in the deposition reaction chamber; and the upper part is provided with a second on-line temperature monitoring device and an illumination system. The invention can be used for depositing a low-cost non-defective silicon dioxide film.

Owner:夏洋

Method and apparatus for growing a composite metal sulphide photocatalyst thin film

ActiveUS20070122564A1Investigating moving fluids/granular solidsScattering properties measurementsSulfideZinc sulfide

A method and apparatus are provided for growing a composite metal sulphide photcatalyst thin film, wherein photochemical deposition and chemical bath deposition are both performed for growing the composite metal sulphide thin film, such as (AgInS2)x / (ZnS)2(1-x), wherein x is 0-1.

Owner:IND TECH RES INST

Efficient visible-light responsive noble metal-Bi-TiO2 nanometer heterojunction photocatalyst and preparation method thereof

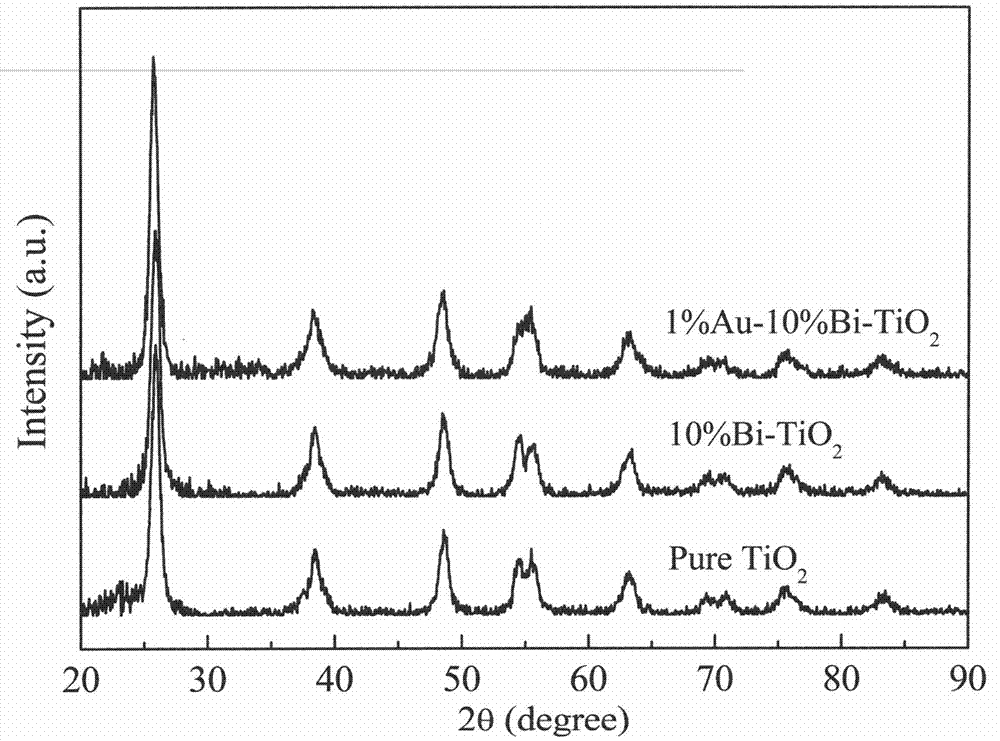

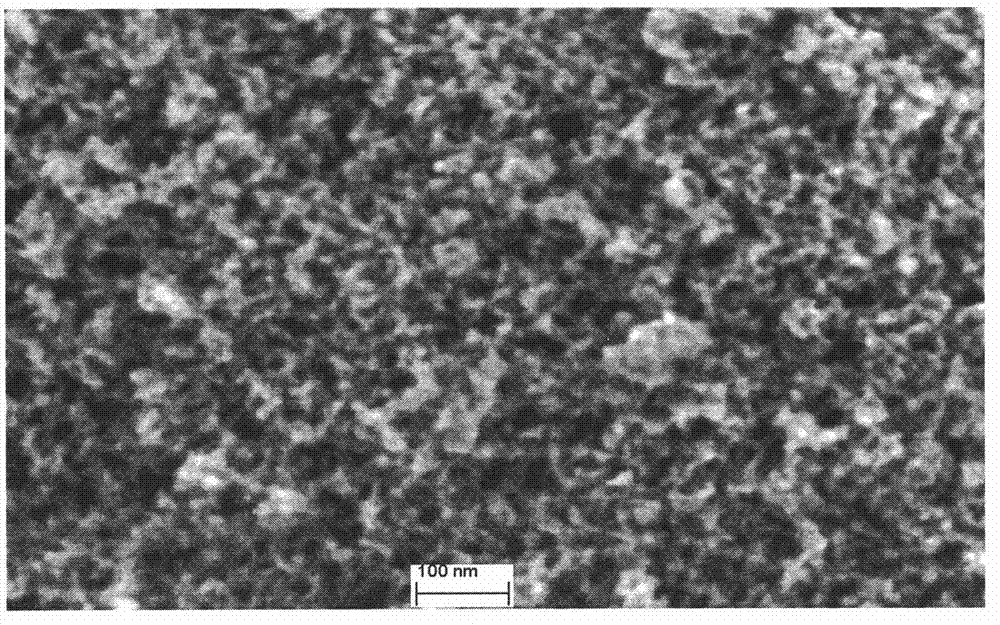

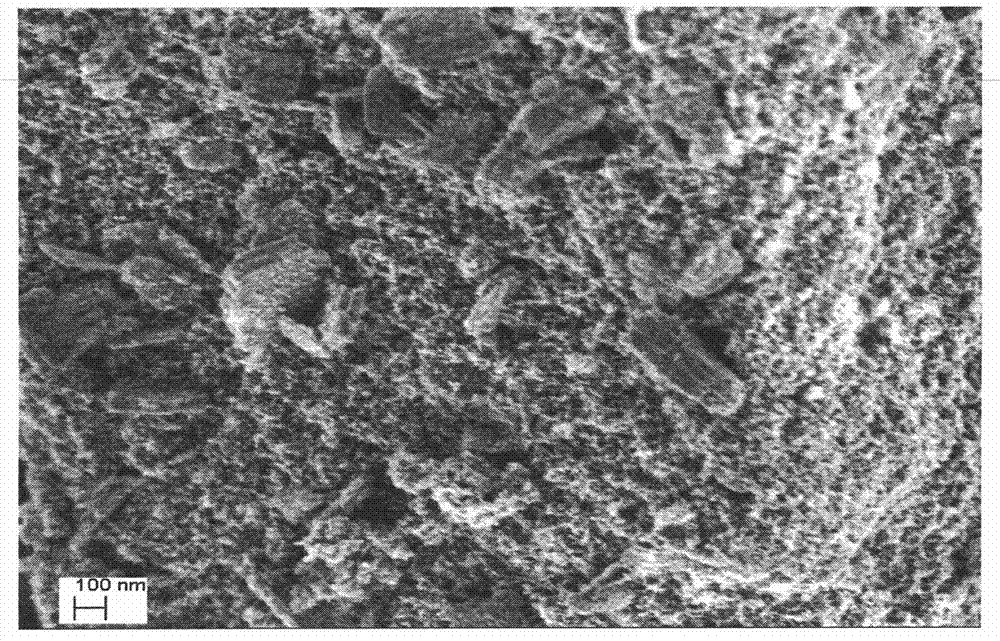

InactiveCN103933976AWide spectral response rangeEfficient degradationMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionUltraviolet lights

The invention belongs to the technical field of TiO2 base photocatalysts, and in particular relates to an efficient visible-light responsive noble metal-Bi-TiO2 nanometer heterojunction photocatalyst and a preparation method thereof. The preparation method is characterized in that Bi ion-doped TiO2 which has the controllable shape and grain size, and visible-light responsive capacity is synthesized by adopting a hydrothermal-solvothermal reaction, the spectral responsive range of the photocatalyst is expanded, compared with the common TiO2, the noble metal-Bi-TiO2 nanometer heterojunction photocatalyst obtained through light chemical sedimentation on the surface of the noble metal can further separate photoproduction electron and hole, the photocatalytic efficiency of products is further improved, and an organic pollutant is effectively degraded in a short time, the products obtained by adopting the technology have the high visible-light catalytic activity, the photocatalytic efficiency for degrading the organic pollutant, of parts of the products under visible light is higher than that of the international standard P25 under ultraviolet light. The preparation method is simple and easy, has no pollution, strong practicability, and wide product application range.

Owner:伊文涛

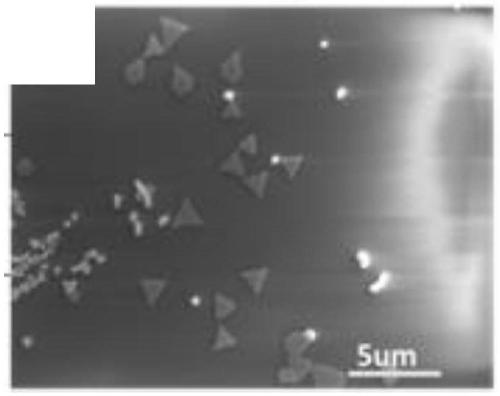

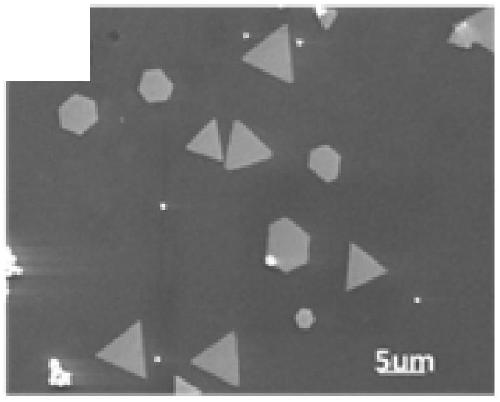

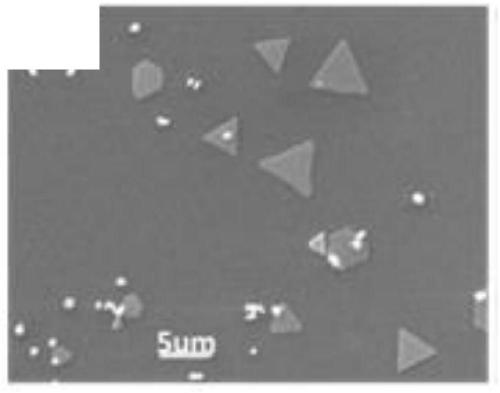

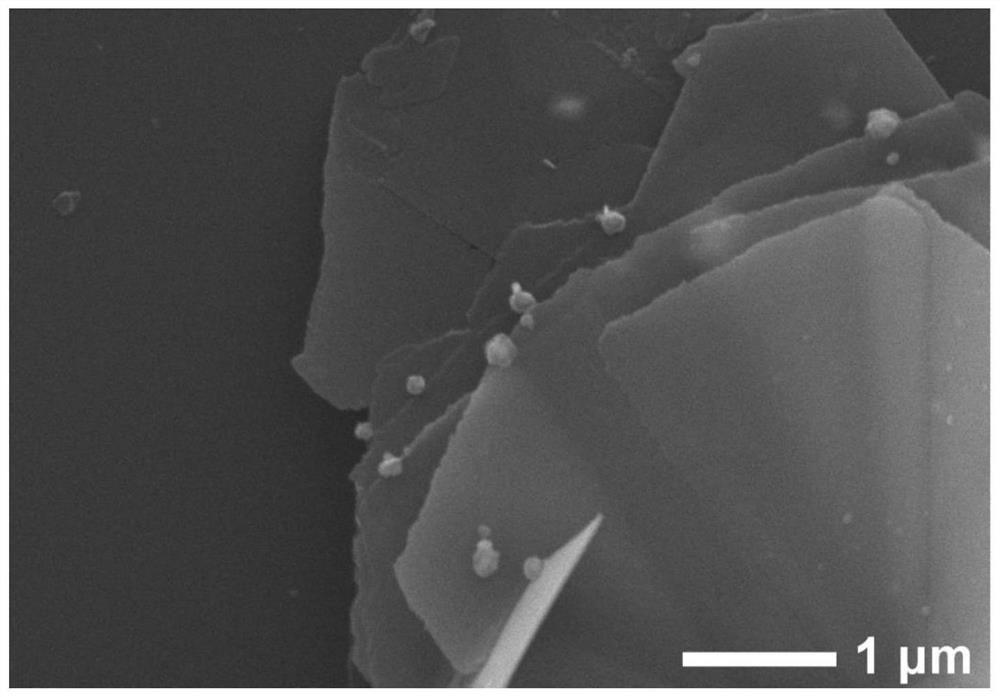

Preparation method of gold nanometer triangular sheet with surface enhanced raman scattering

ActiveCN109837531APrecise size controlSimple methodRaman scatteringNanotechnologyChemical synthesisUltraviolet lights

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Method and apparatus for growing a composite metal sulphide photocatalyst thin film

ActiveUS7677198B2Investigating moving fluids/granular solidsScattering properties measurementsMaterials scienceMetal

A method and apparatus are provided for growing a composite metal sulphide photcatalyst thin film, wherein photochemical deposition and chemical bath deposition are both performed for growing the composite metal sulphide thin film, such as (AgInS2)x / (ZnS)2(1-x), wherein x is 0-1.

Owner:IND TECH RES INST

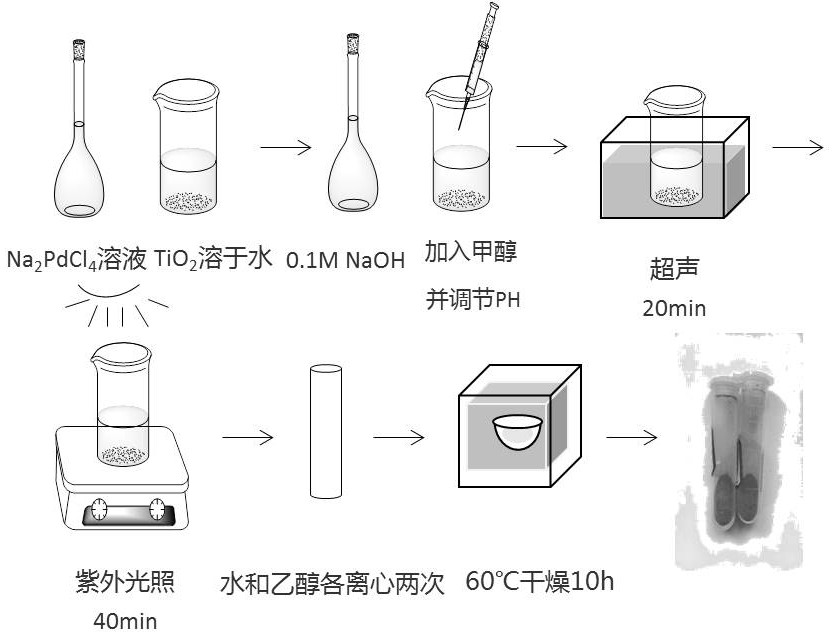

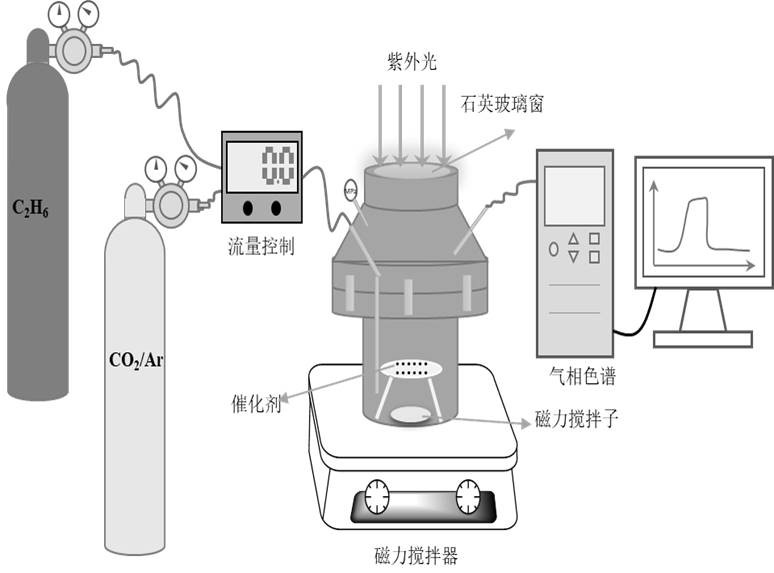

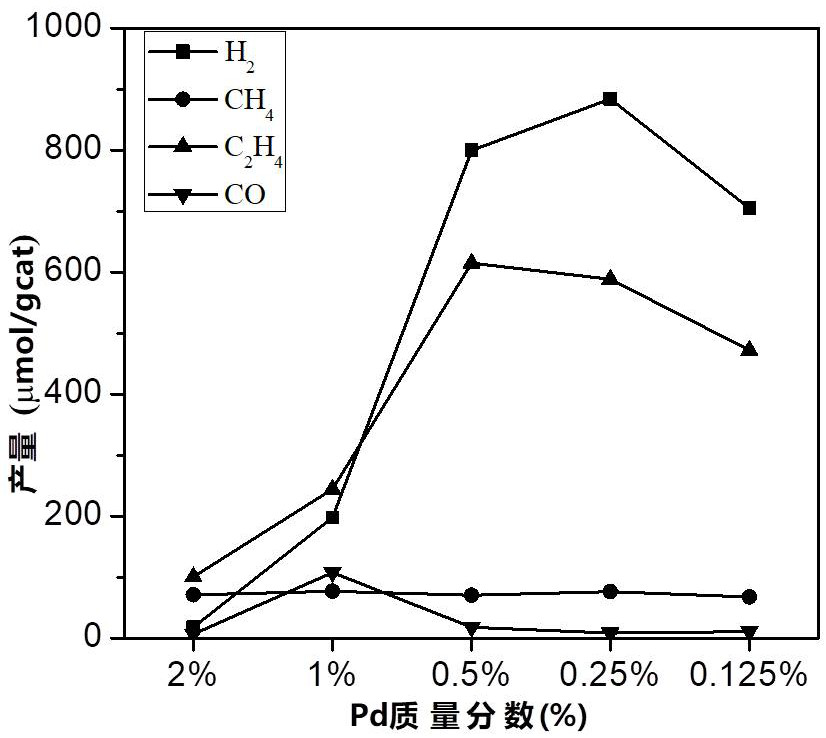

Metal-loaded catalytic system for preparing ethylene by photocatalytic oxidation of ethane dehydrogenation and direct ethane dehydrogenation

The invention discloses a metal-loaded catalytic system for photocatalytic oxidation of ethane dehydrogenation and photocatalytic direct ethane dehydrogenation. The catalyst is prepared through methods of photochemical deposition, impregnation reduction and the like, the metal loading capacity and the pH of carrier suspension liquid are controlled, metal particles are evenly dispersed on the surface of a carrier, and metal-loaded catalytic system samples with different particle size distribution are obtained. The sample is used for a reaction system for preparing ethylene by photocatalytic ethane dehydrogenation, and can simultaneously realize the effects of preparing ethylene by photocatalytic CO2 oxidation of ethane dehydrogenation and preparing ethylene by direct ethane dehydrogenationunder a photocatalytic condition. The metal-loaded catalytic system is simple, a method for simultaneously controlling the loading capacity and adjusting the pH value is adopted, and the process conditions and the operation method are short in preparation process. The catalytic system has the characteristics of relatively good activity and high ethylene selectivity when being used for photo-catalyzing ethane direct dehydrogenation or oxidizing ethane for dehydrogenation, has a guiding effect on later development, and has a very good application prospect.

Owner:SICHUAN UNIV

Method for preparing cadmium-sulfide nano film based on deep ultraviolet photochemical bath deposition

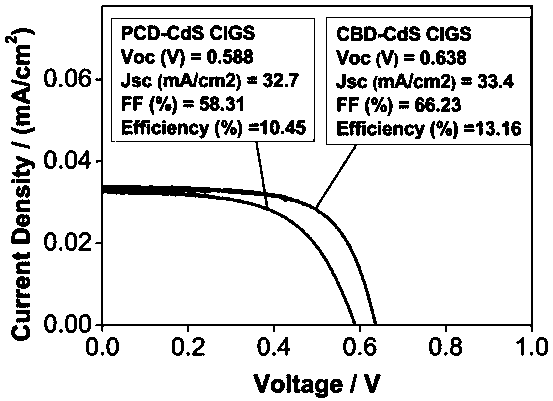

ActiveCN106486557AIncrease profitImprove controllabilityCadmium sulfidesPhotovoltaic energy generationIndiumFilm base

The invention, which relates to the technical field of the semiconductor optoelectronic material, provides a method for preparing a cadmium-sulfide nano film based on deep ultraviolet photochemical bath deposition. A metal source CdSO4, a sulfur source Na2S2O3, and a sulfur source release control agent containing SO3<2-> and an H2SO4 solution are mixed to obtain a deposition solution, wherein the pH of the deposition solution is stabilized to be 3.5 to 4.0; a substrate is immersed into the deposition solution, wherein the distance between the surface of the deposition solution and the upper surface of the substrate is less than 1mm; and radiation is carried out by using LED deep-ultraviolet light, thereby forming a cadmium-sulfide nano film. Using the method, the sulfur source release can be controlled, thereby improving homogeneity of film growing. Compared with the common photochemical deposition technology, the provided method has the following beneficial effects: the deep ultraviolet light source has the low power and the heating effect is low; on the basis of the optical design, the deep ultraviolet light intensity is uniform in a fixed range; and the high-quality cadmium-sulfide nano film that can meet the requirement of the buffer layer of the copper-indium-gallium-selenium solar cell, has high uniformity, and is in close contact with the substrate can be prepared.

Owner:LINGNAN NORMAL UNIV

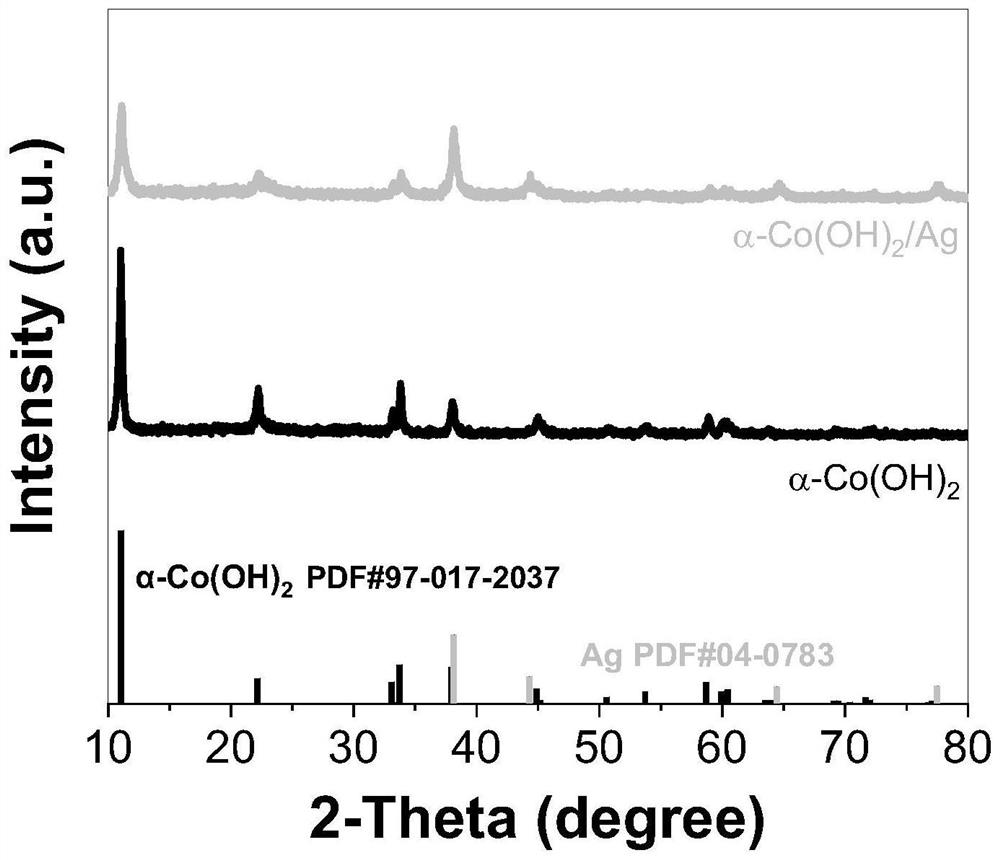

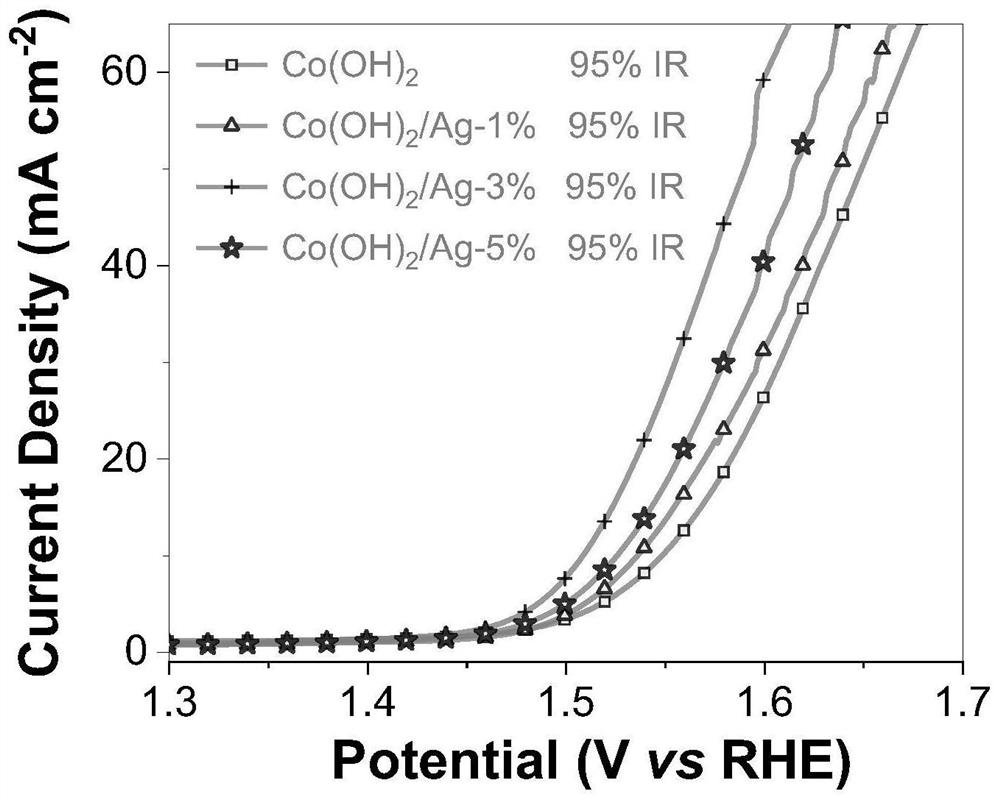

Preparation method of Ag/alpha-Co(OH)2 oxygen evolution catalyst

ActiveCN113134361AImprove responseExcellent OER activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsElectrolytic agentPtru catalyst

The invention belongs to the field of new energy materials and electrochemical catalysis, and discloses a preparation method and application of a silver-loaded Ag / alpha-Co(OH)2 oxygen evolution catalyst. The transition metal oxygen evolution catalyst is prepared by a simple and convenient photochemical deposition method, and due to the introduction of noble metal Ag, the catalytic material generates a surface plasma resonance effect under laser irradiation, so that the electro-catalytic oxygen evolution reaction performance is further improved. The composite catalyst shows excellent OER catalytic performance in 1.0 M KOH electrolyte under the irradiation of green laser with different powers. The overpotential of the Ag / alpha-Co(OH) (2-3%) is 278 mV under the current density of 10 mA cm <-2 >. During green laser irradiation, the overpotentials are respectively reduced to 269mV and 243mV under the light intensity of 500mW and 1000mW. The catalyst provided by the invention can be used as an electrocatalyst in the field of renewable fuel cells, rechargeable metal-air cells or electrolyzed water.

Owner:JIANGSU UNIV

Room temperature formaldehyde purification catalyst and preparation method thereof

InactiveCN111686799AAvoid instabilityGood synergyOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationPtru catalystPhysical chemistry

The invention discloses a room temperature formaldehyde purification catalyst. Cerium-zirconium composite oxide with a mesoporous structure and titanium-based solid ionic liquid are combined to serveas a composite carrier, PdPt alloy loaded through a photochemical deposition method serves as an active component, the mass fraction of Pt in the catalyst is 0.02 wt%-0.5 wt%, and the mass fraction ofPd in the catalyst is 1 wt%-5 wt%. The catalyst is prepared by the following steps: (1) preparing a mesoporous cerium-zirconium composite oxide; (2) synthesizing an ionic liquid precursor NMMPS; (3)synthesizing the mesoporous cerium-zirconium composite oxide and a titanium-based solid ionic liquid composite carrier; and (4) loading an active component PdPt. According to the preparation method, metal cations and organic cations are doped, noble metal PdPt is loaded by adopting an ultraviolet chemical deposition method, and the prepared catalyst has excellent moisture resistance and stabilityon the premise of keeping relatively high catalytic efficiency.

Owner:闫英辉

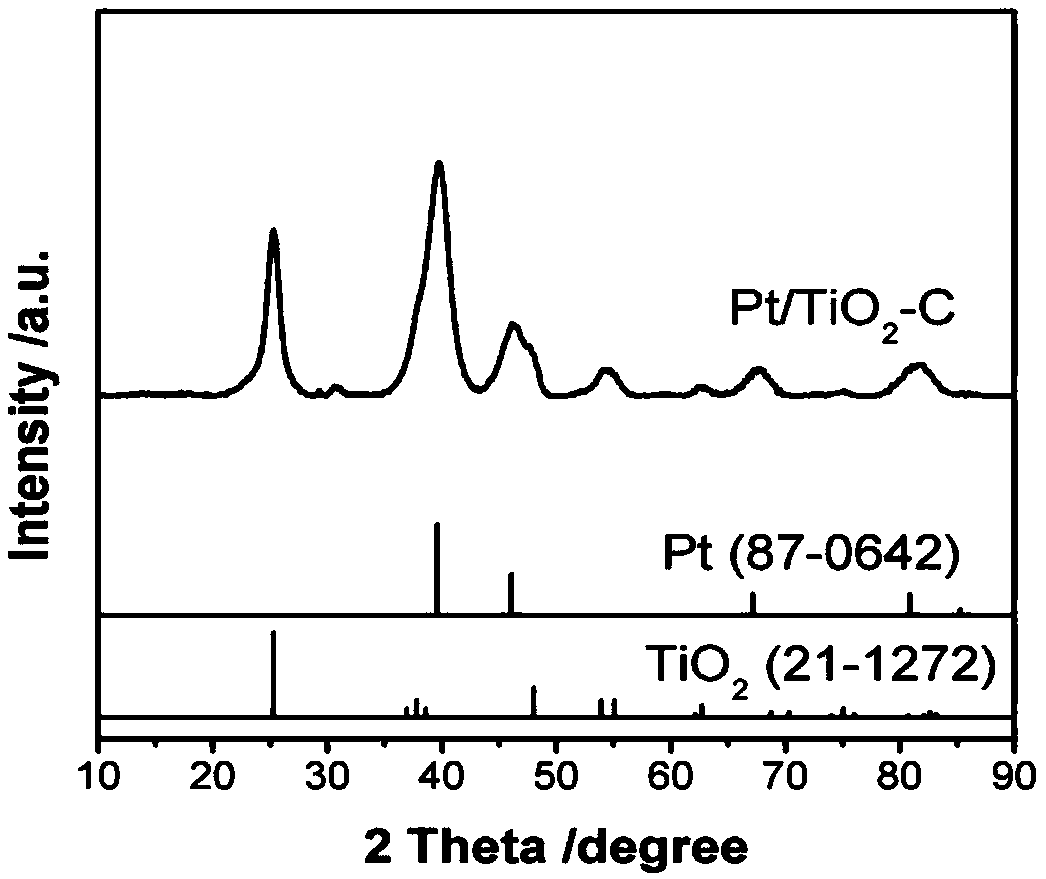

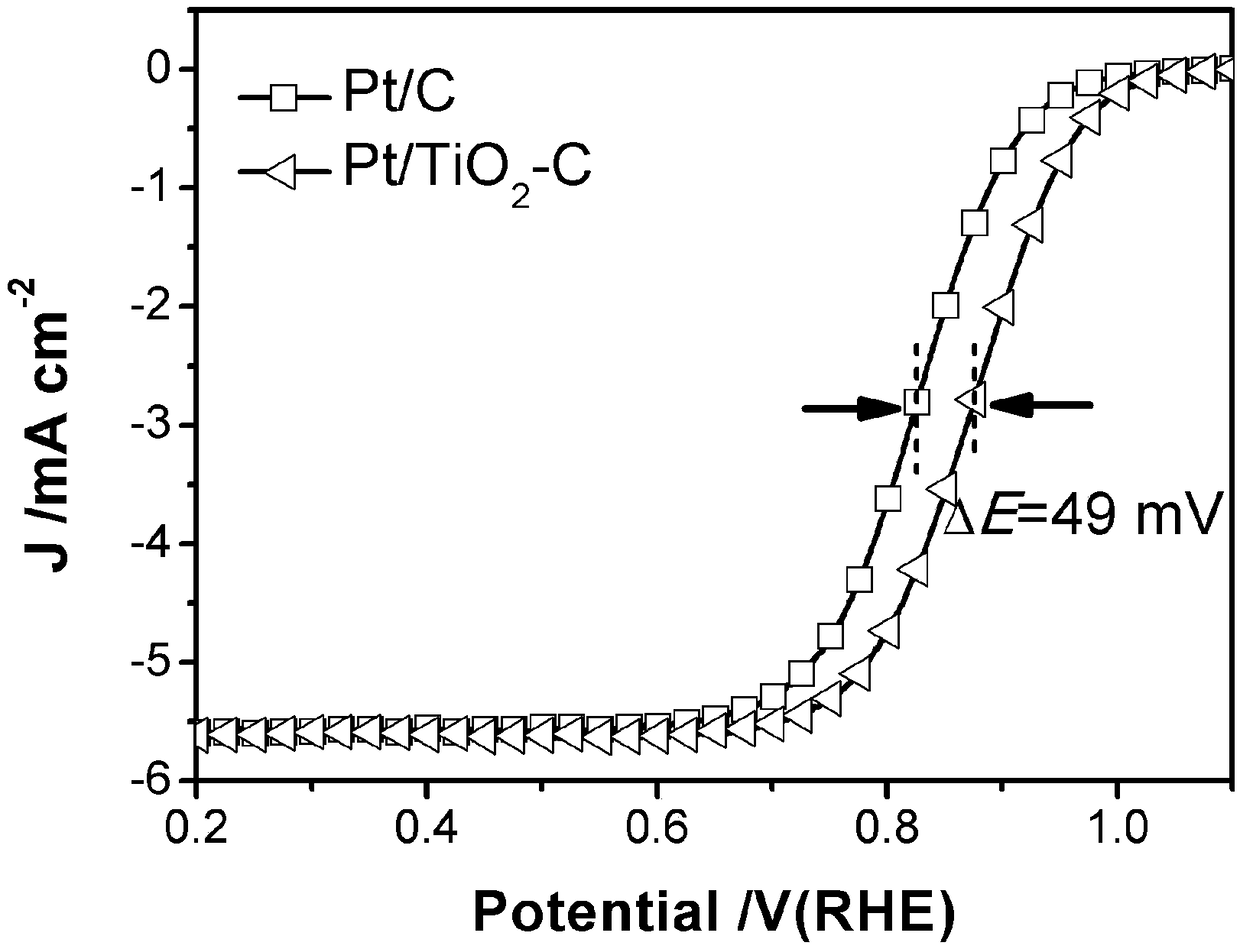

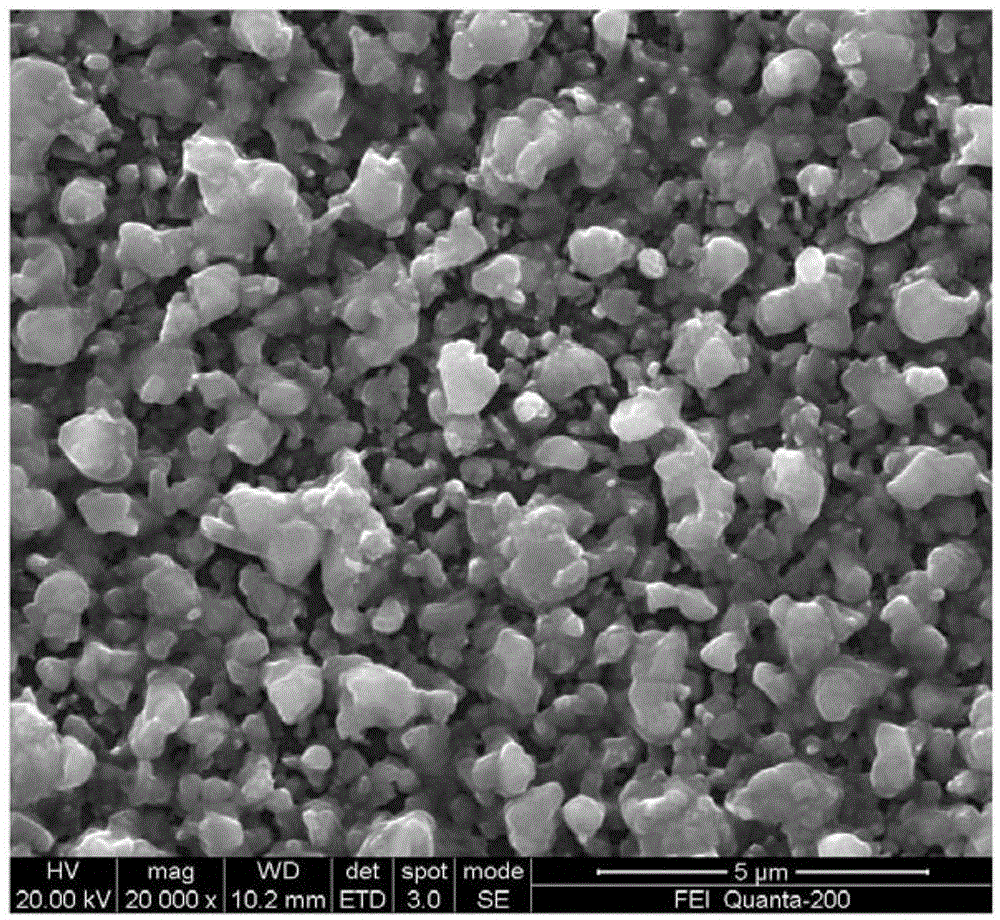

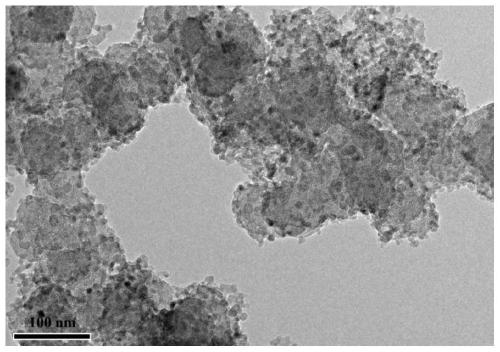

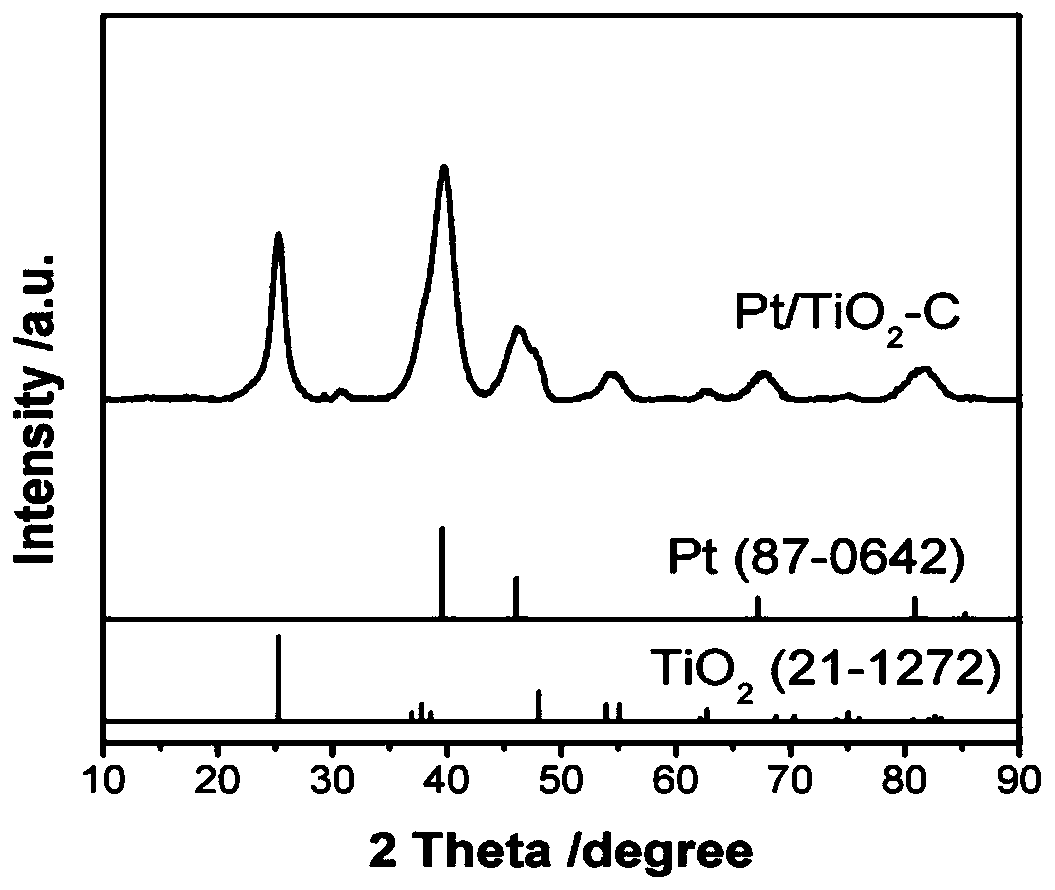

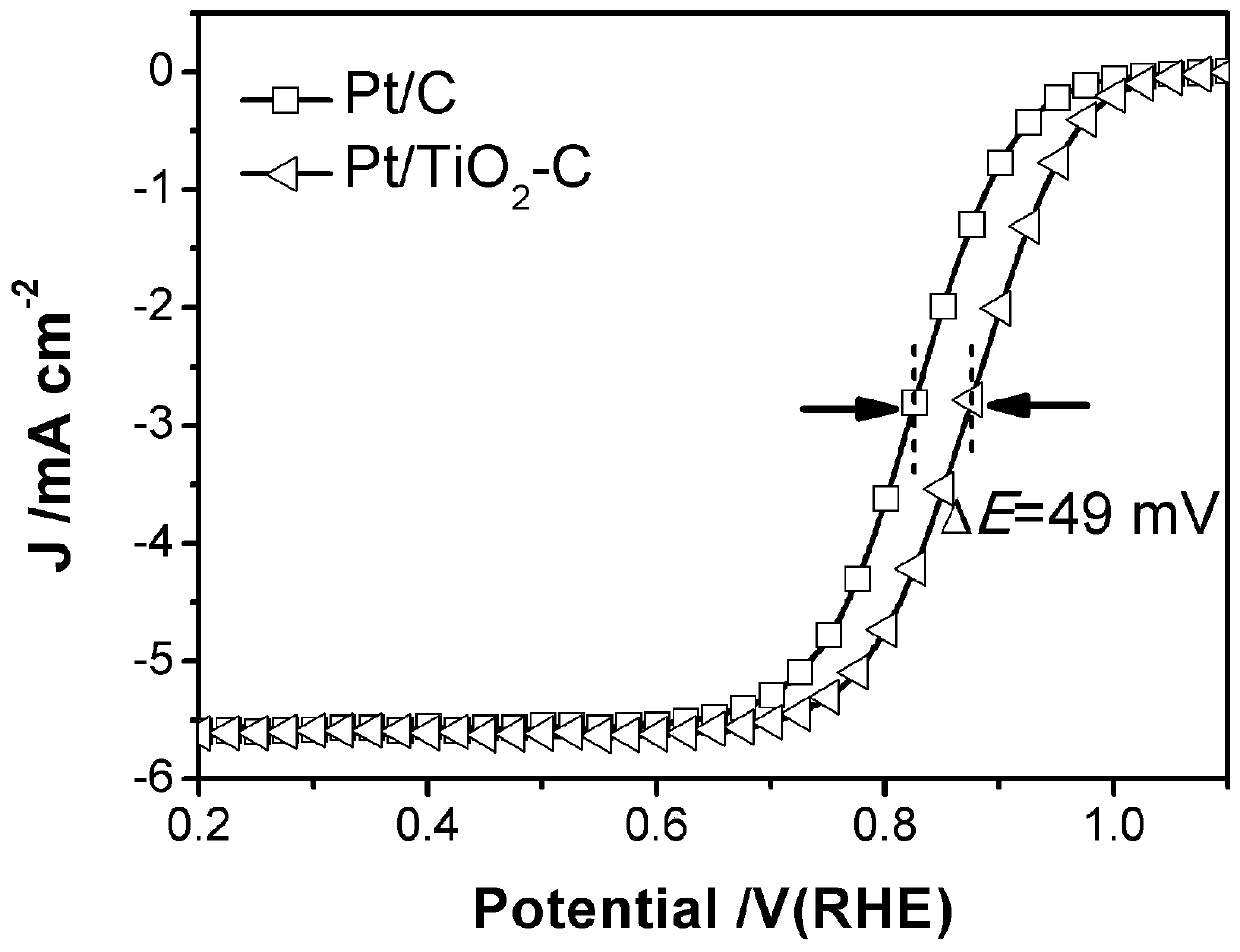

Titanium dioxide-carbon composite carrier supported platinum electrocatalyst and preparation method thereof

ActiveCN108607546AReduce loadHigh activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon compositesPlatinum

The invention provides a titanium dioxide-carbon composite carrier supported platinum electrocatalyst and a preparation method thereof. The titanium dioxide-carbon composite carrier supported platinumelectrocatalyst comprises a titanium dioxide-carbon carrier and platinum particles, wherein the titanium dioxide-carbon carrier is carbon black loaded with titanium dioxide on the surface, and the platinum particles are loaded on the surface of titanium dioxide. The titanium dioxide-carbon composite carrier supported platinum electrocatalyst provided by the invention contributes to transferring electrons from the carrier to the catalyst, so that the stability of the catalyst activity can be greatly improved. The titanium oxide-carbon composite carrier supported platinum electrocatalyst is prepared by liquid phase assembly and photochemical deposition, and TiO2 can be uniformly loaded on the surface of spherical carbon black. Therefore, the activity of the catalyst is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

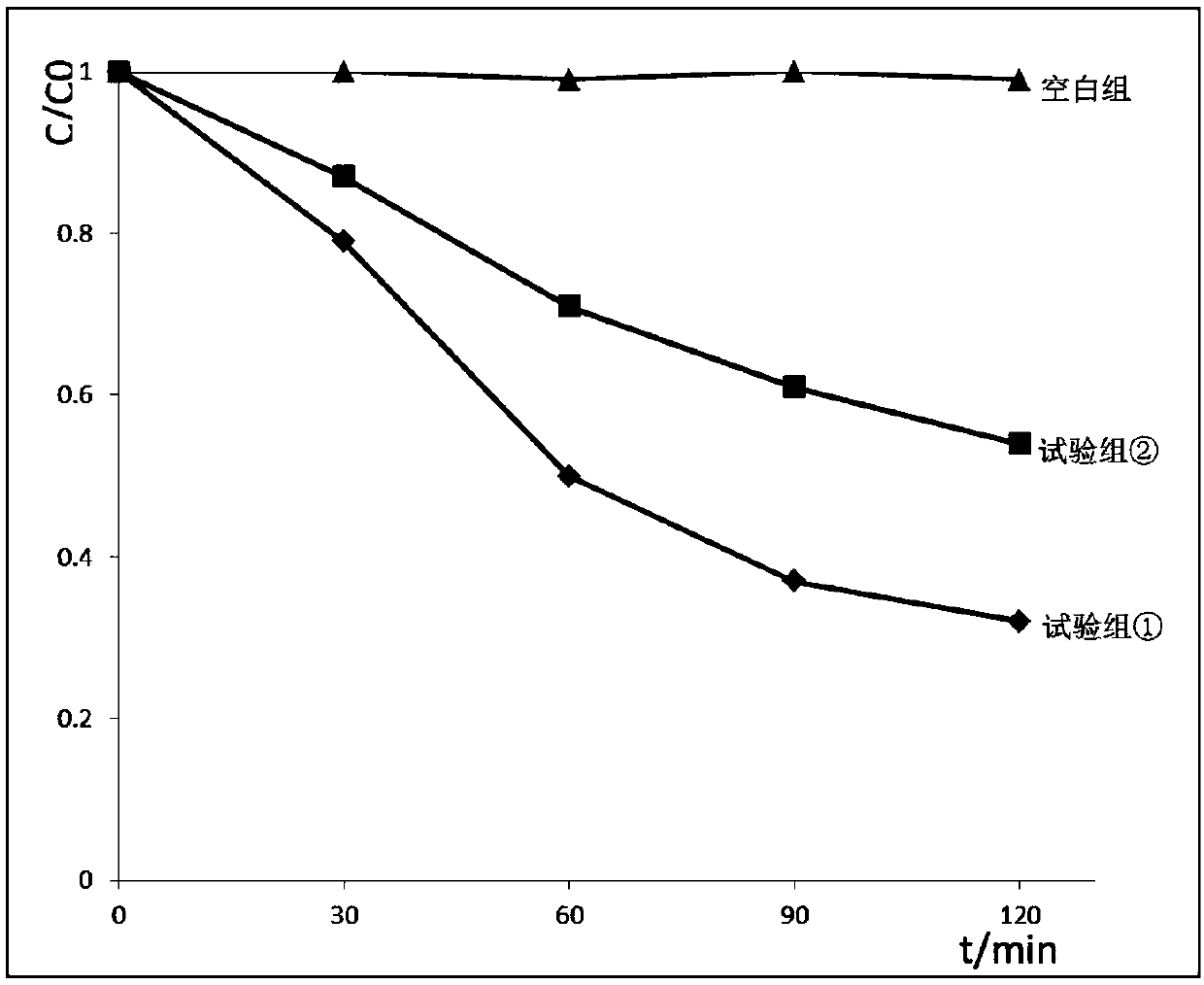

Preparation method of organic matter photolysis catalyst

PendingCN109574132AFast degradation rateWater/sewage treatment by irradiationWater treatment compoundsUltravioletSingle crystal

The invention discloses a preparation method of an organic matter photolysis catalyst. the preparation method includes: taking a single crystal wafer made of a ferroelectric material as a substrate; enabling a forward polarized face of the substrate to be upward, and dropwise adding a silver nitrate water solution onto the forward polarized face; using ultraviolet to irradiate the silver nitrate water solution for photochemical deposition reaction to prepare nano silver particles on the forward polarized face of the substrate, and oxidizing the nano silver particles into nano silver oxide particles to obtain a finished product. By adopting the preparation method, the photocatalyst having efficient photodegradation effect on organic matter like rhodamine B can be prepared, degradation speedis higher, and degradation rate is higher.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing CIGS film based on photochemistry deposition

ActiveCN104362222AQuality improvementHigh utilization rate of raw materialsFinal product manufactureVacuum evaporation coatingPolymer scienceIndium

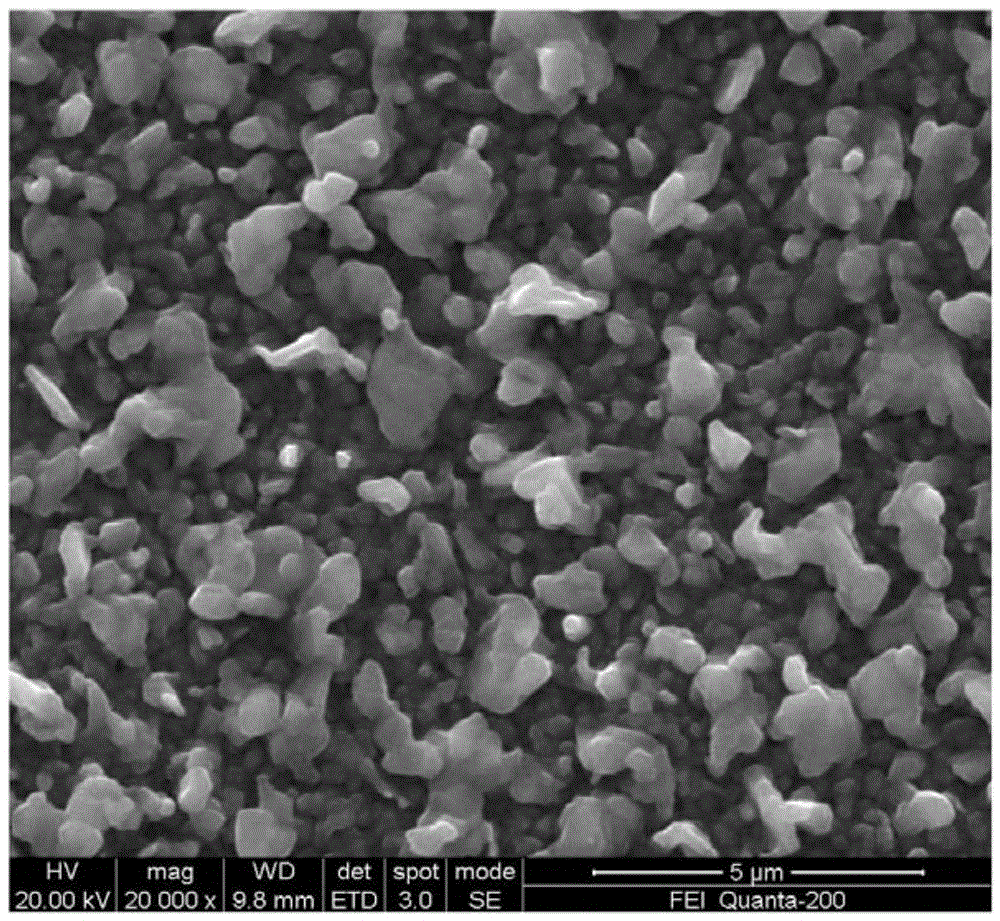

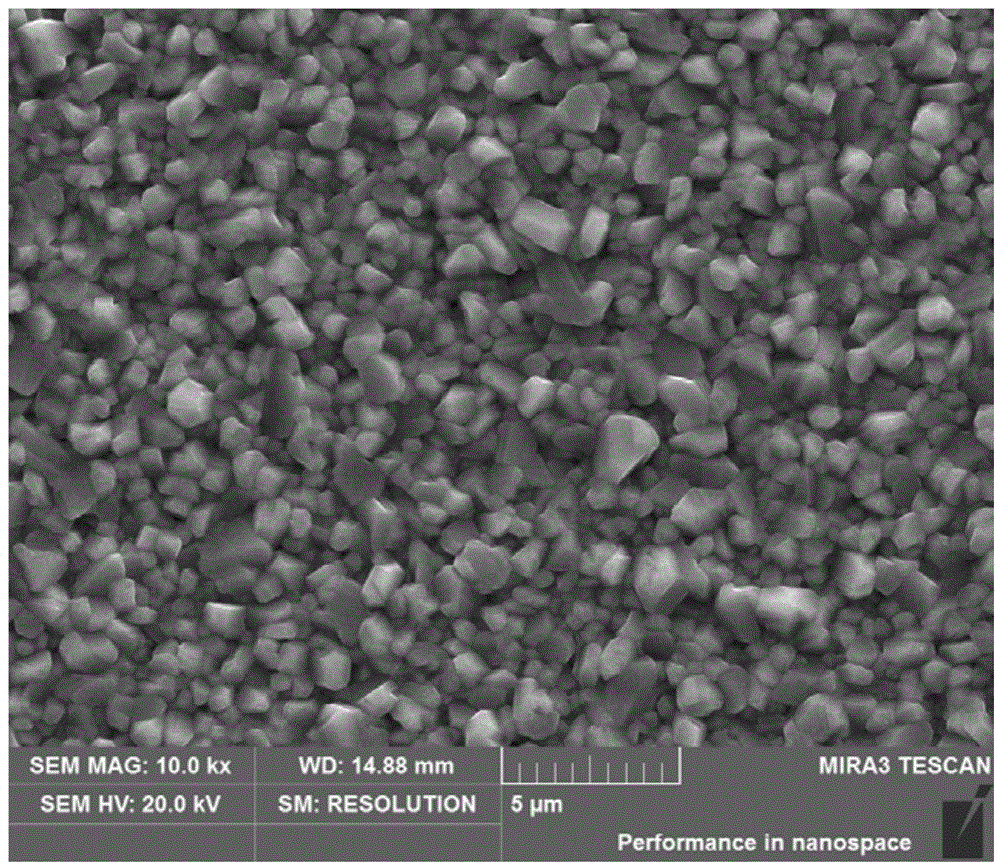

The invention discloses a method for preparing a CIGS film based on photochemistry deposition. According to the method, a conductive substrate is plated with a Se or S film firstly, then the conductive substrate plated with the Se or S film is placed in a solution system containing at least two kinds of indium ions, gallium ions, selenium ions and copper ions and a photoelectron releasing agent for photochemistry deposition, and then the CIGS film is obtained. According to the method, the photochemistry deposition method is successfully applied to the preparation of the CIGS film, the growth situation and morphology of the photochemistry deposition CIGS film can be effectively controlled, the prepared CIGS film is good in surface morphology and high in density, composition is controllable, the problems of poor deposition controllability and film nonuniformity existing in a traditional photochemistry deposition process are effectively solved, the material utilization rate is high, cost is low, and large-scale production and promotion can be achieved.

Owner:CENT SOUTH UNIV

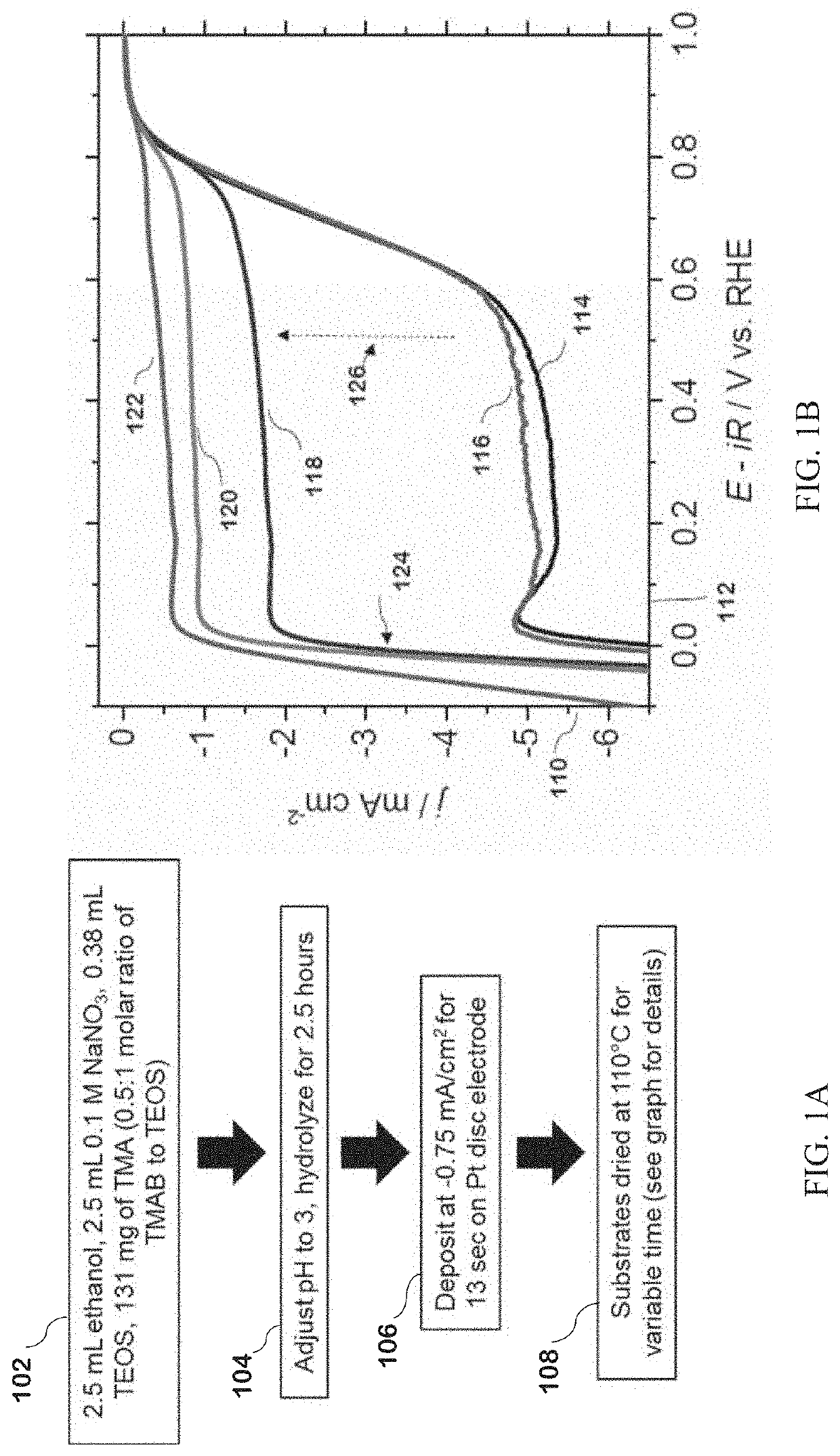

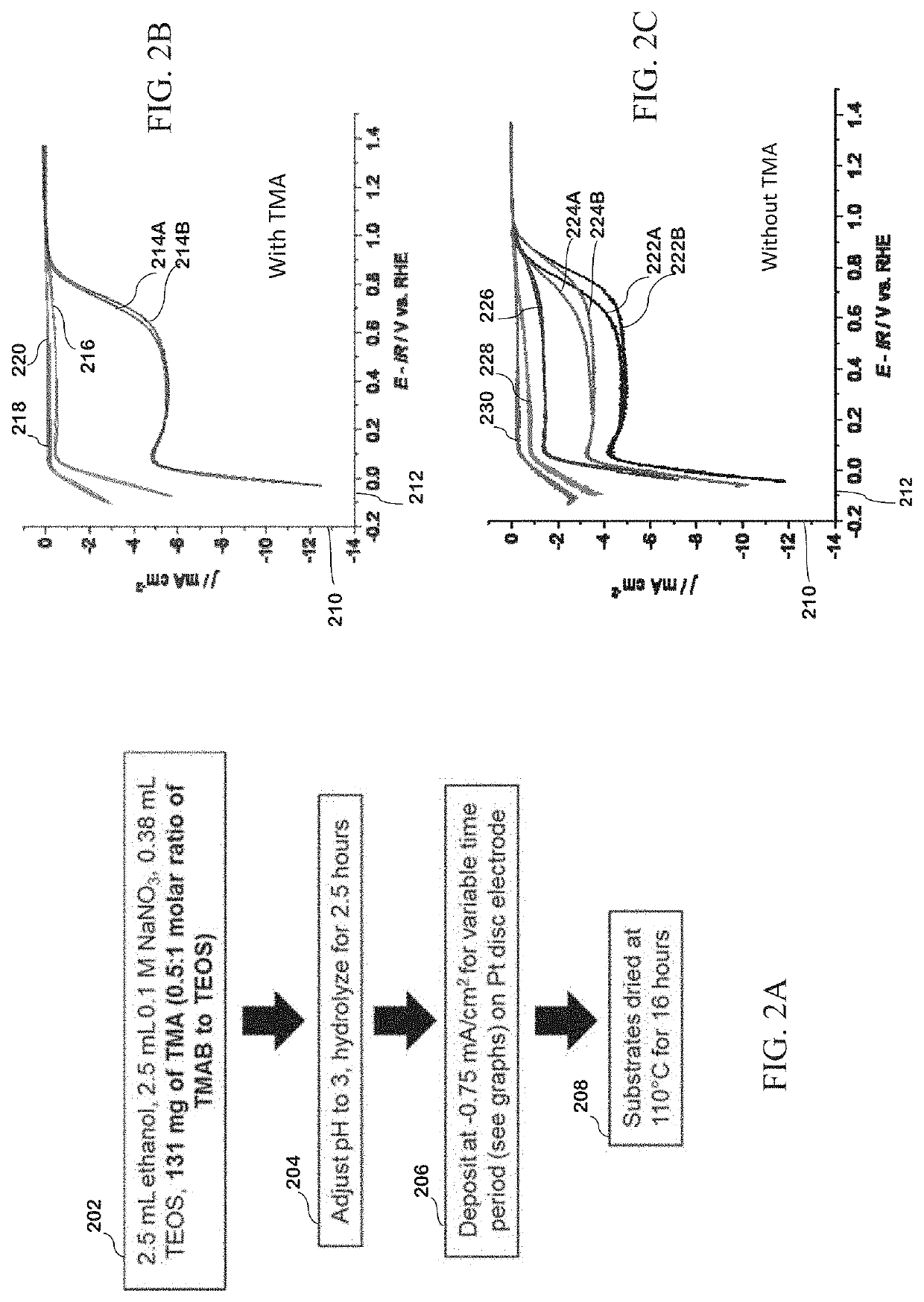

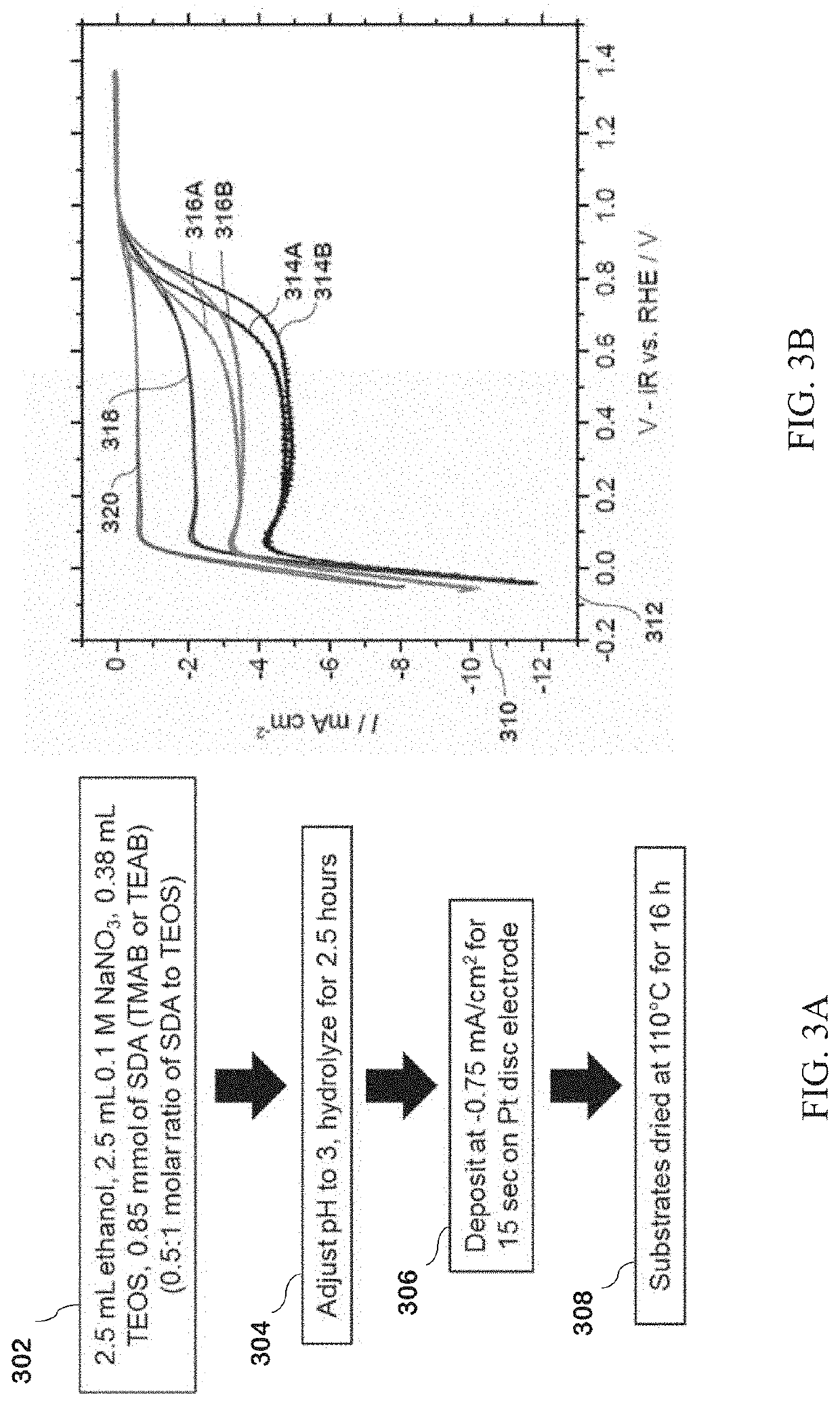

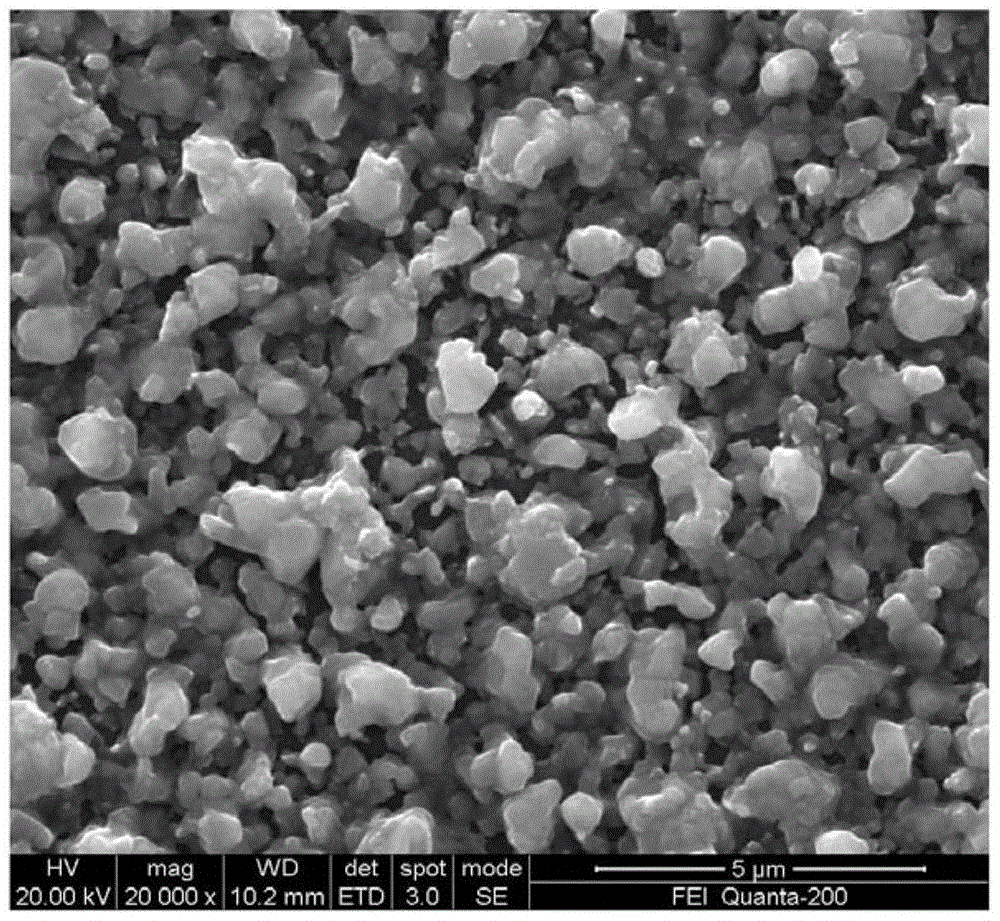

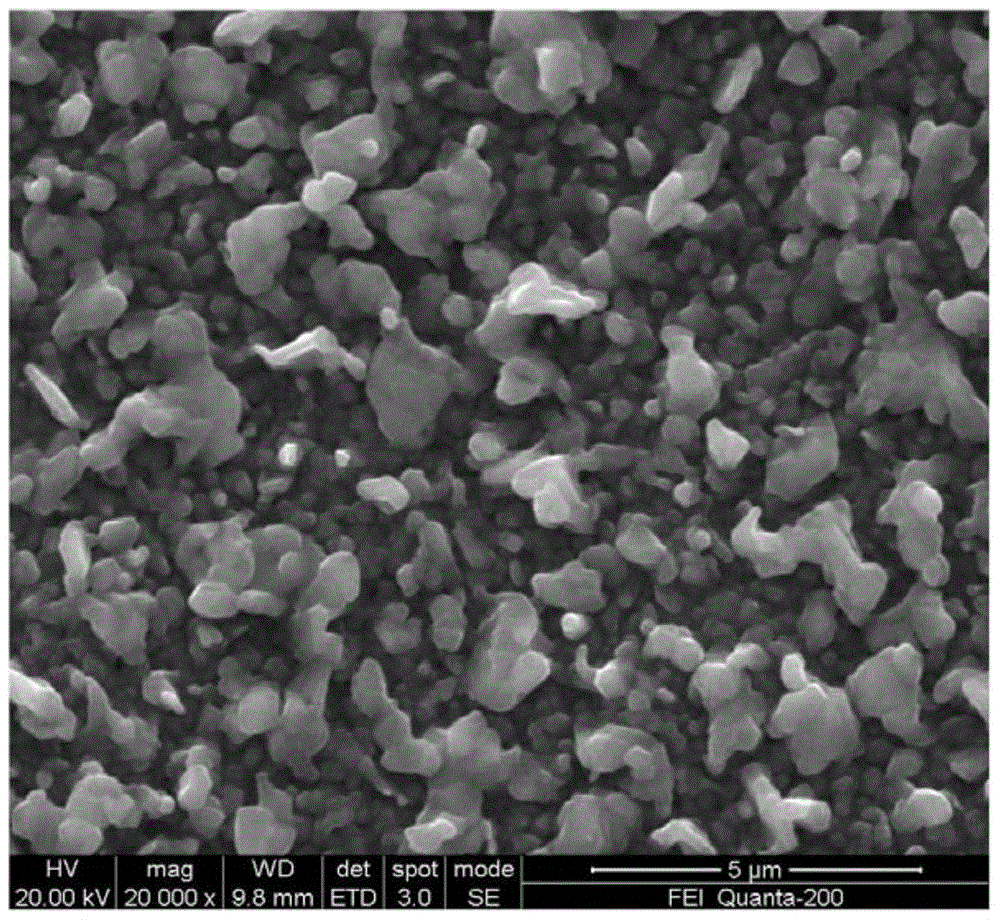

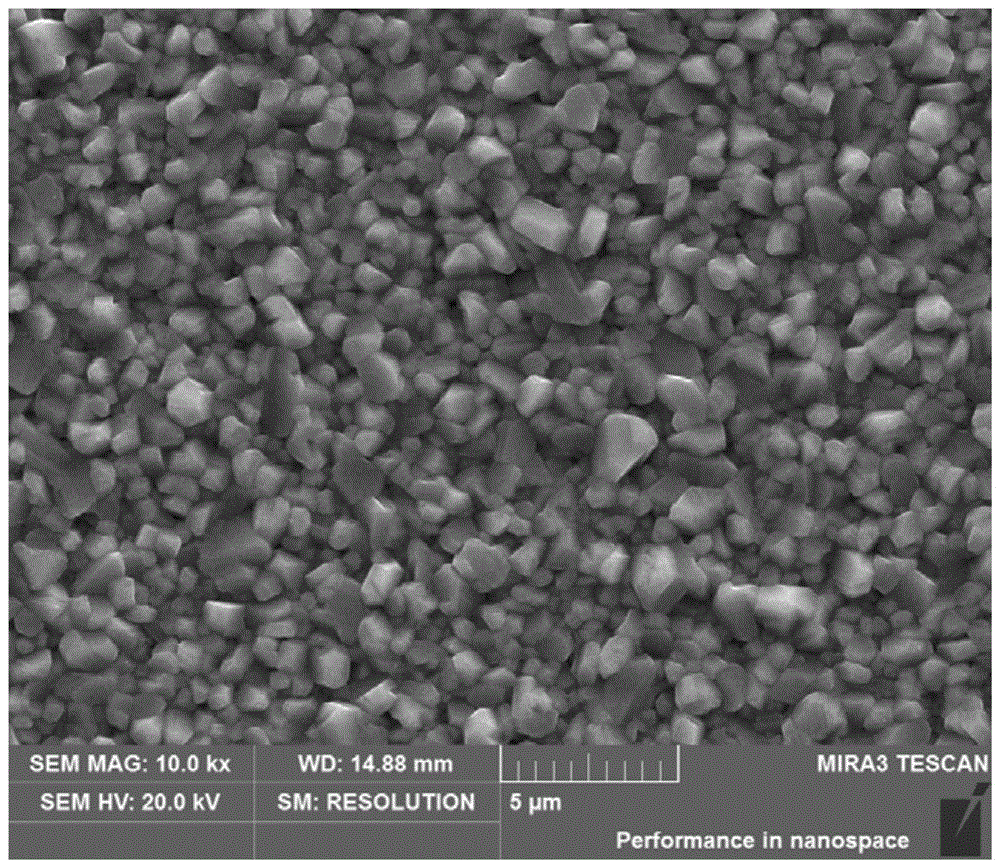

Protection of metal surfaces for selective electrocatalysis and corrosion inhibition

InactiveUS20210115583A1Avoid recombinationAvoid corrosionElectrolytic inorganic material coatingLiquid/solution decomposition chemical coatingMetallic materialsSilicon oxide

Owner:KING ABDULLAH UNIV OF SCI & TECH

Method for preparing noble-metal-supported p-NiO/n-NiFe2O4 composite semiconductor photocatalyst

InactiveCN102389809BSmall particle sizeImprove photocatalytic efficiencyCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSolvent

The invention discloses a method for preparing a noble-metal-supported p-NiO / n-NiFe2O4 composite semiconductor photocatalyst. The method comprises the following steps of: 1, sequentially performing microwave reaction on nickel salt, iron salt, citric acid, alkali and deionized water which are taken as raw materials, performing ultrasonic dispersion, heating and reacting, washing, performing ultrasonic dispersion, filtering, drying, roasting and grinding to obtain NiFe2O4 solid powder; 2, sequentially reacting the NiFe2O4 solid powder, nickel salt, alkali and deionized water which are taken asraw materials, performing ultrasonic dispersion, dehydrating under reduced pressure, performing heat treatment, washing, performing ultrasonic dispersion, filtering, drying, roasting and grinding to obtain p-NiO / n-NiFe2O4 solid powder; and 3, sequentially stirring the p-NiO / n-NiFe2O4 solid powder, a noble metal compound, ethanol and deionized water which are taken as raw materials and dissolving,performing ultrasonic dispersion, performing photochemical deposition reaction, removing a solvent under reduced pressure, performing heat treatment, washing, filtering, drying, roasting and grindingto obtain the noble-metal-supported p-NiO / n-NiFe2O4 composite semiconductor photocatalyst.

Owner:NANJING TECH UNIV

A method for preparing copper indium gallium selenide thin films based on photochemical deposition

ActiveCN104362222BQuality improvementHigh utilization rate of raw materialsFinal product manufactureVacuum evaporation coatingIndiumCopper indium gallium selenide solar cells

Owner:CENT SOUTH UNIV

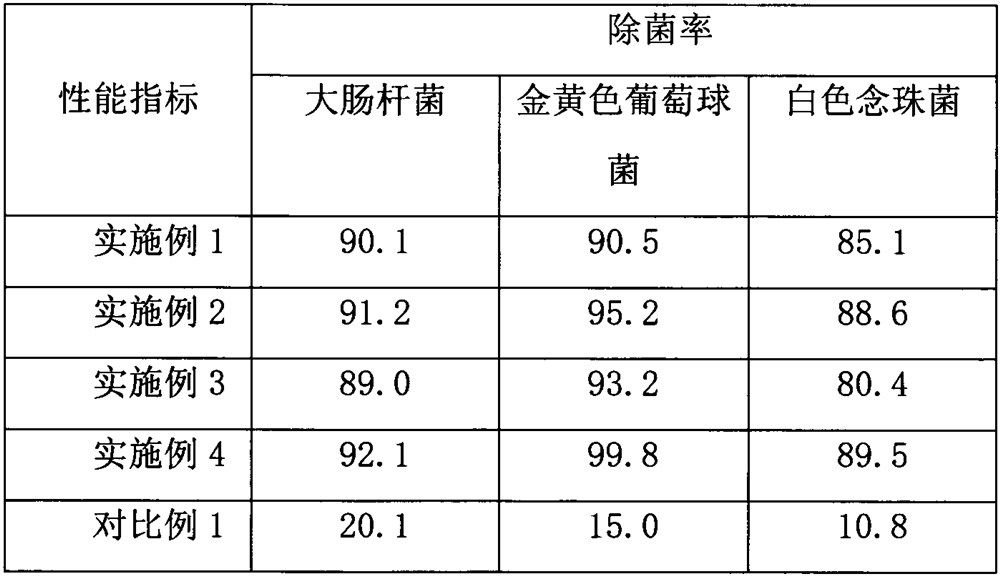

Silver-titanium dioxide-chitosan composite antibacterial filter material and preparation method thereof

PendingCN112387006ALarge specific surface areaFully contactedFiltration separationMicroorganismSilver particles

The invention belongs to the technical field of air antibiosis, and provides a silver-titanium dioxide-chitosan composite antibacterial filter material and a preparation method thereof, and the filtermaterial can effectively inhibit and kill microorganisms in air. The method includes: firstly synthesizing titanium dioxide-chitosan hydrogel microbeads, and then uniformly dispersing nano-silver particles on the surface of the titanium dioxide-chitosan composite material through a photochemical deposition method to prepare the silver-titanium dioxide-chitosan composite antibacterial filter material. The antibacterial filter material has the outstanding characteristics and excellent effects that: the nano-silver particles have a very high specific surface area and can be in full contact withair, the sterilization efficiency is improved, zero-valent nano-silver particles are adopted, the antibacterial effect is better than that of common nano-silver, and the prepared antibacterial filtermaterial can be widely applied to indoor air sterilization.

Owner:SHENZHEN MEIZHAO ENERGY & ENVIRONMENT TECH

Platinum electrocatalyst supported on titania-carbon composite carrier and preparation method thereof

ActiveCN108607546BHigh activityImprove stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon compositesPlatinum

The invention provides a titanium dioxide-carbon composite carrier supported platinum electrocatalyst and a preparation method thereof. The titanium dioxide-carbon composite carrier supported platinumelectrocatalyst comprises a titanium dioxide-carbon carrier and platinum particles, wherein the titanium dioxide-carbon carrier is carbon black loaded with titanium dioxide on the surface, and the platinum particles are loaded on the surface of titanium dioxide. The titanium dioxide-carbon composite carrier supported platinum electrocatalyst provided by the invention contributes to transferring electrons from the carrier to the catalyst, so that the stability of the catalyst activity can be greatly improved. The titanium oxide-carbon composite carrier supported platinum electrocatalyst is prepared by liquid phase assembly and photochemical deposition, and TiO2 can be uniformly loaded on the surface of spherical carbon black. Therefore, the activity of the catalyst is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

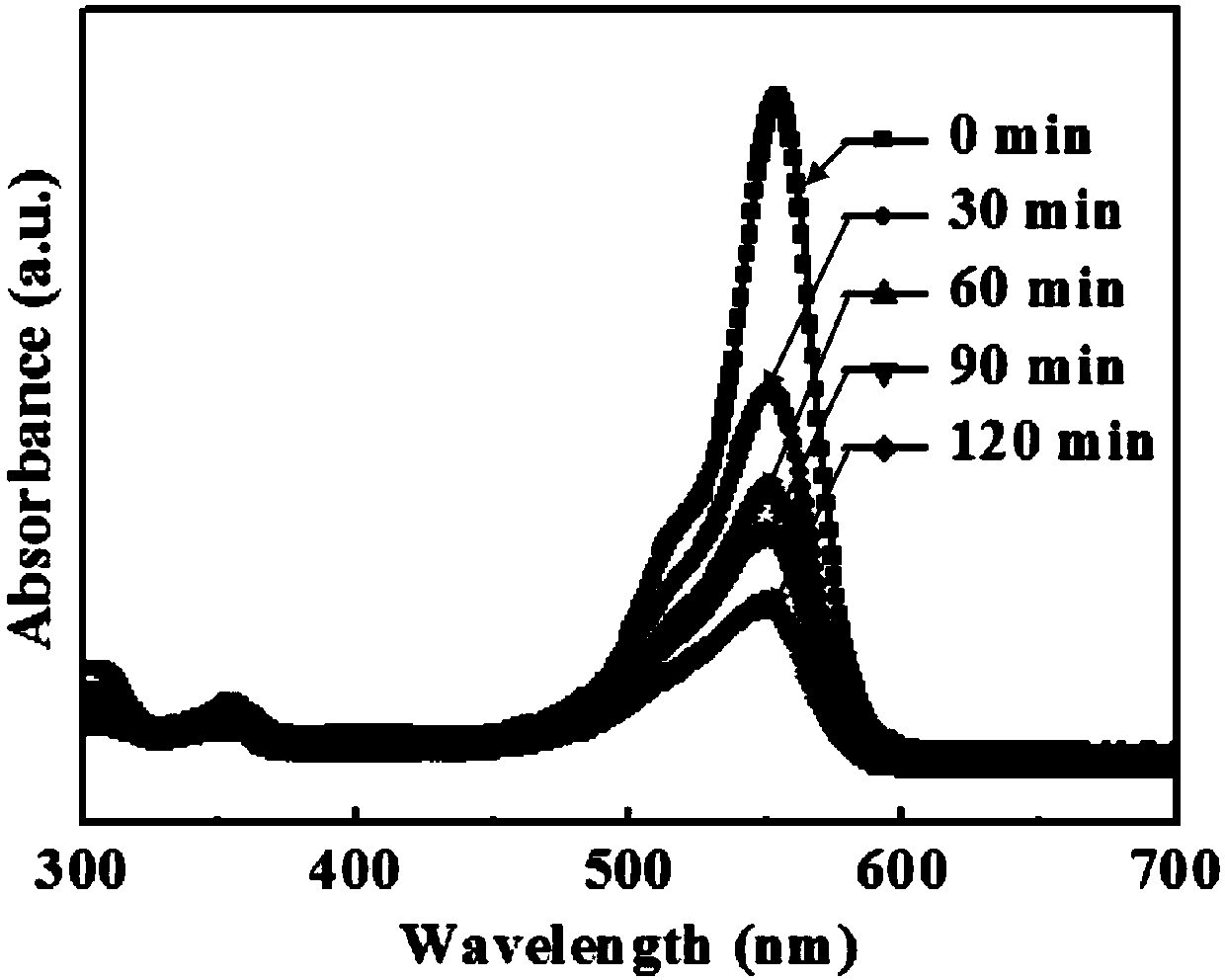

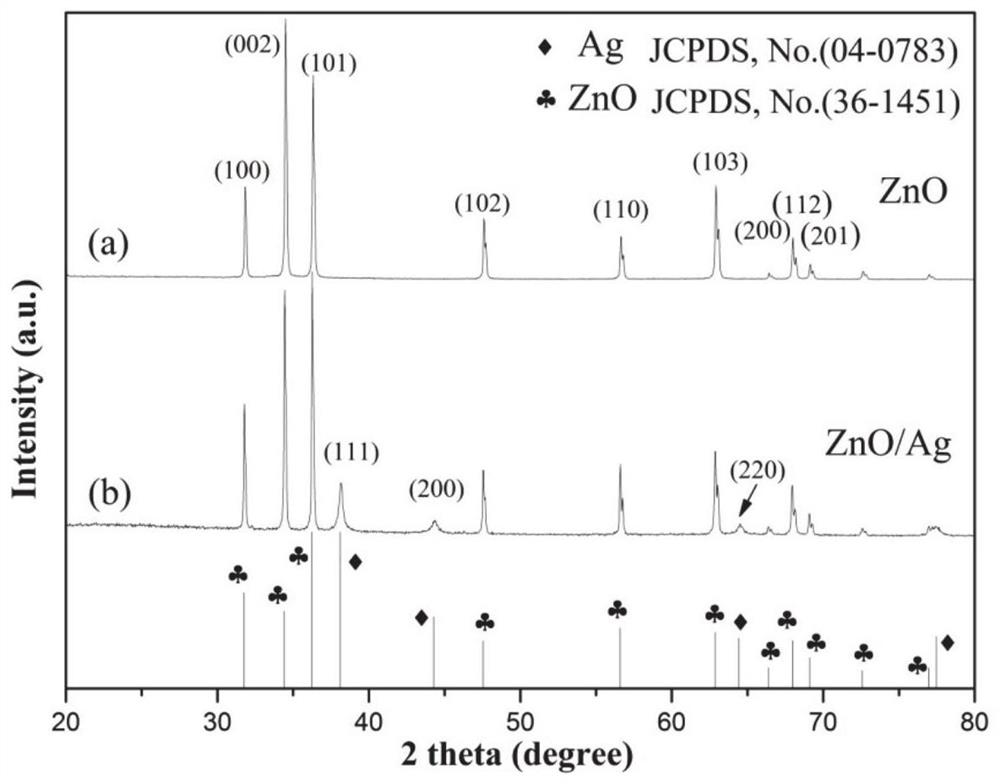

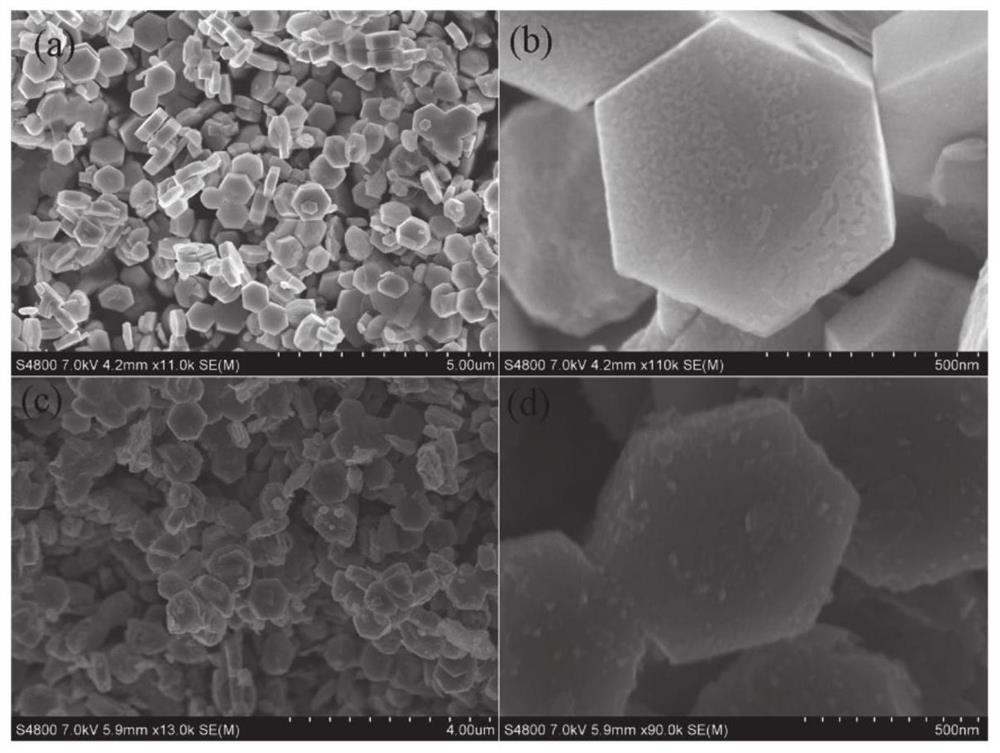

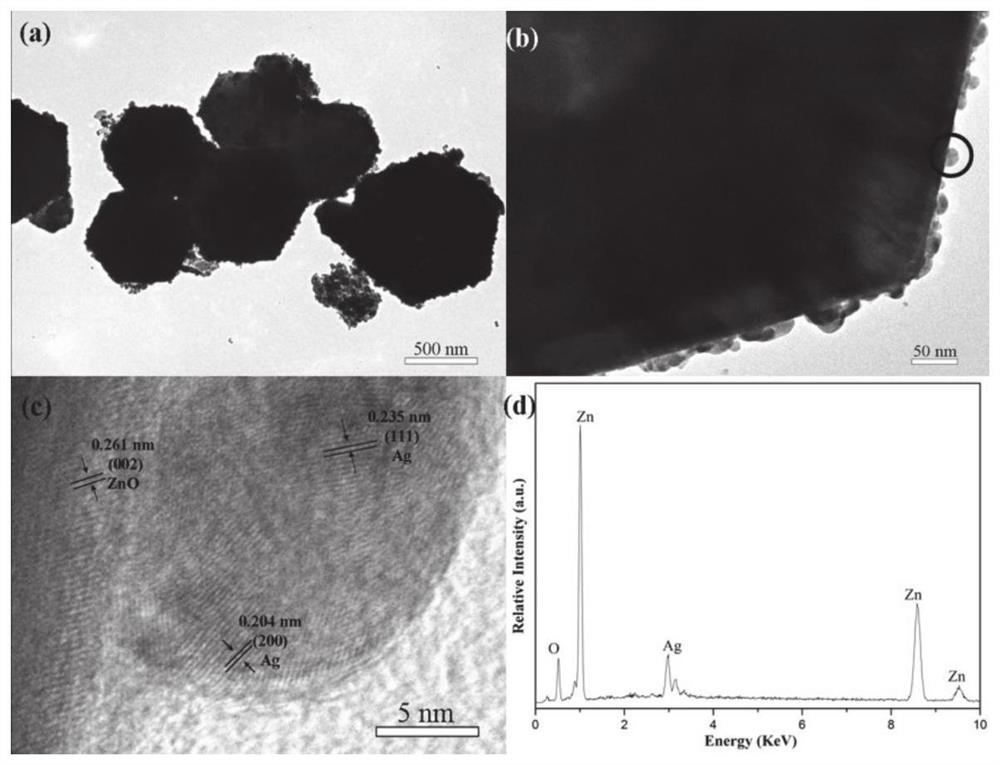

Ag/ZnO hexagonal composite nano sheet as well as preparation method and application thereof

PendingCN113083300APlay the role of electron absorption and captureStrong visible light absorptionWater/sewage treatment by irradiationWater treatment compoundsPhoto catalysisSemiconductor

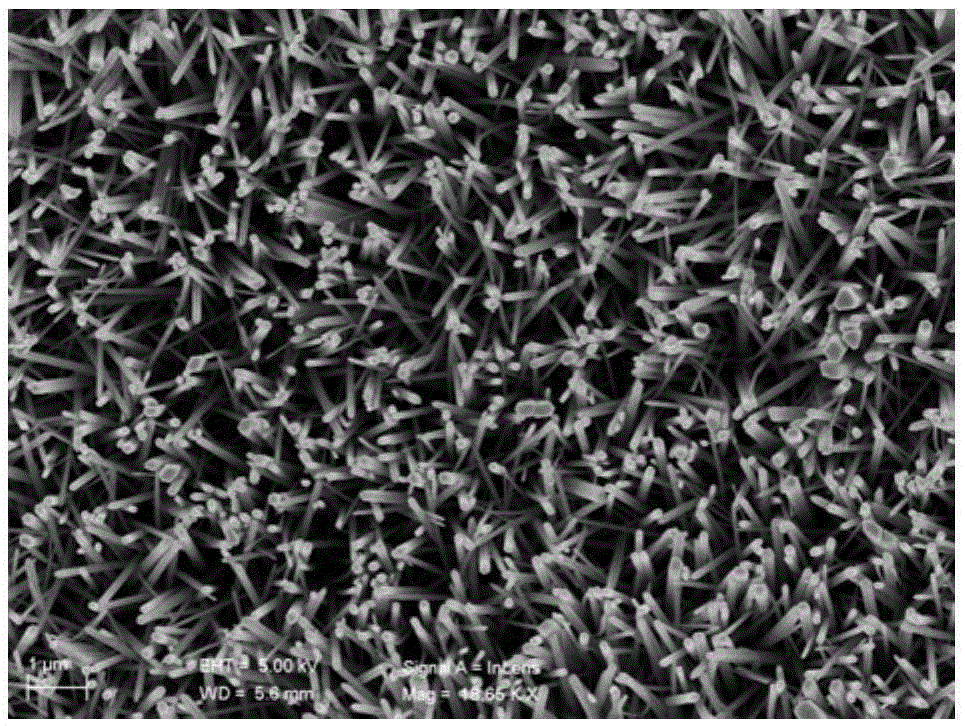

The invention belongs to the field of semiconductor nano materials, and particularly relates to an Ag / ZnO hexagonal composite nano sheet and a preparation method and application thereof. The preparation method comprises the following steps: firstly, preparing a ZnO hexagonal nano sheet through a photo-chemical deposition process, then putting the ZnO hexagonal nano sheet into a silver nitrate solution, and carrying out ultraviolet light treatment to obtain the Ag / ZnO hexagonal composite nano sheet. The Ag / ZnO hexagonal composite nano sheet is prepared by adopting a two-step method, so that Ag particles can be highly dispersed on the hexagonal ZnO nano sheet, the Ag particles can play a role in electron absorption and capture on the surface of a semiconductor more favorably, and the composite material shows higher visible light absorption capacity and shows more excellent photocatalytic activity on degradation of organic pollutants under visible light.

Owner:QILU UNIV OF TECH

A kind of multifunctional integrated fe-al-ta eutectic composite material and preparation method thereof

ActiveCN110904389BIncrease profitExtended service lifeLiquid surface applicatorsChemical vapor deposition coatingElectron bunchesPrepared Material

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Process for manufacturing equipment for treating pollution water body

InactiveCN100415660CImprove processing efficiencyReduce chemical oxygen demandCatalyst carriersWater/sewage treatment by irradiationSlurryPhotochemical deposition

A process for preparing the sewage treating apparatus includes such steps as preparing the slurry of anatase-type TiO2 nano-particle by sol-gel method, preparing photocatalyst Ag / TiO2 by photochemical deposition method, adding TiO2 to AgNO3 solution, adsorbing while stirring, radiating by low-pressure Hg lamp, distilled water washing to remove excessive Ag ions, braiding glass fibers to obtain needed shape, immersing it in modified TiO2 nano-particles slurry, sintering and installing it to the frame made of plastic tube.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

A method for preparing cadmium sulfide nano film by deep ultraviolet photochemical water bath deposition

ActiveCN106486557BIncrease profitImprove controllabilityCadmium sulfidesPhotovoltaic energy generationWater bathsIndium

The invention, which relates to the technical field of the semiconductor optoelectronic material, provides a method for preparing a cadmium-sulfide nano film based on deep ultraviolet photochemical bath deposition. A metal source CdSO4, a sulfur source Na2S2O3, and a sulfur source release control agent containing SO3<2-> and an H2SO4 solution are mixed to obtain a deposition solution, wherein the pH of the deposition solution is stabilized to be 3.5 to 4.0; a substrate is immersed into the deposition solution, wherein the distance between the surface of the deposition solution and the upper surface of the substrate is less than 1mm; and radiation is carried out by using LED deep-ultraviolet light, thereby forming a cadmium-sulfide nano film. Using the method, the sulfur source release can be controlled, thereby improving homogeneity of film growing. Compared with the common photochemical deposition technology, the provided method has the following beneficial effects: the deep ultraviolet light source has the low power and the heating effect is low; on the basis of the optical design, the deep ultraviolet light intensity is uniform in a fixed range; and the high-quality cadmium-sulfide nano film that can meet the requirement of the buffer layer of the copper-indium-gallium-selenium solar cell, has high uniformity, and is in close contact with the substrate can be prepared.

Owner:LINGNAN NORMAL UNIV

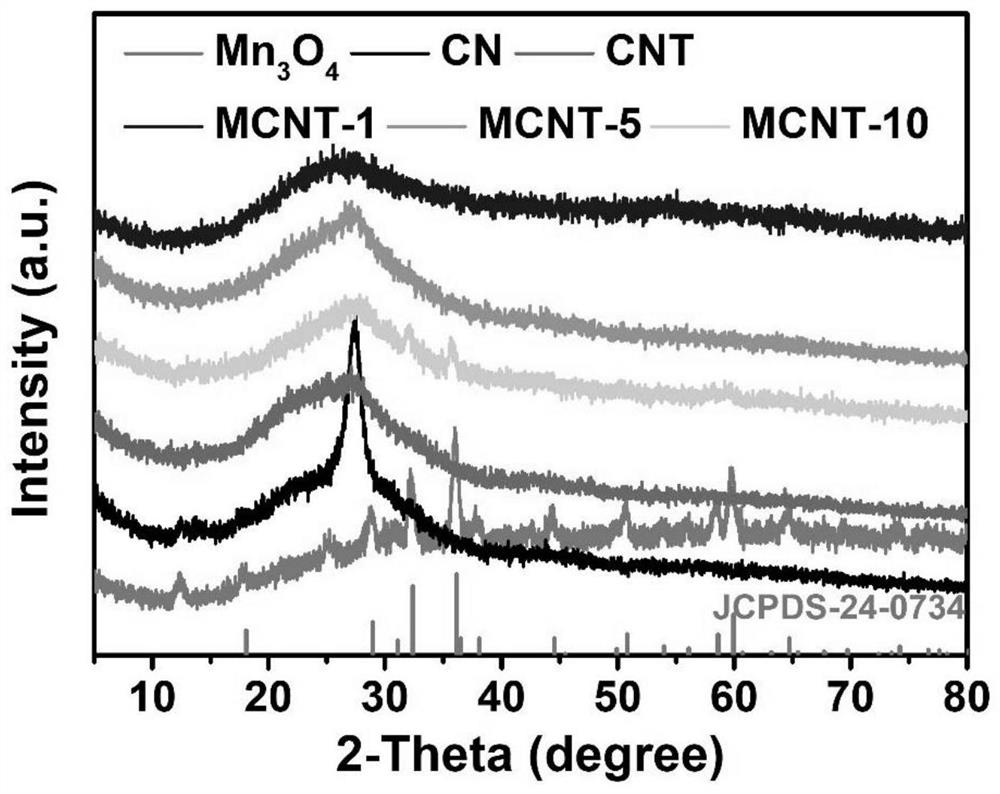

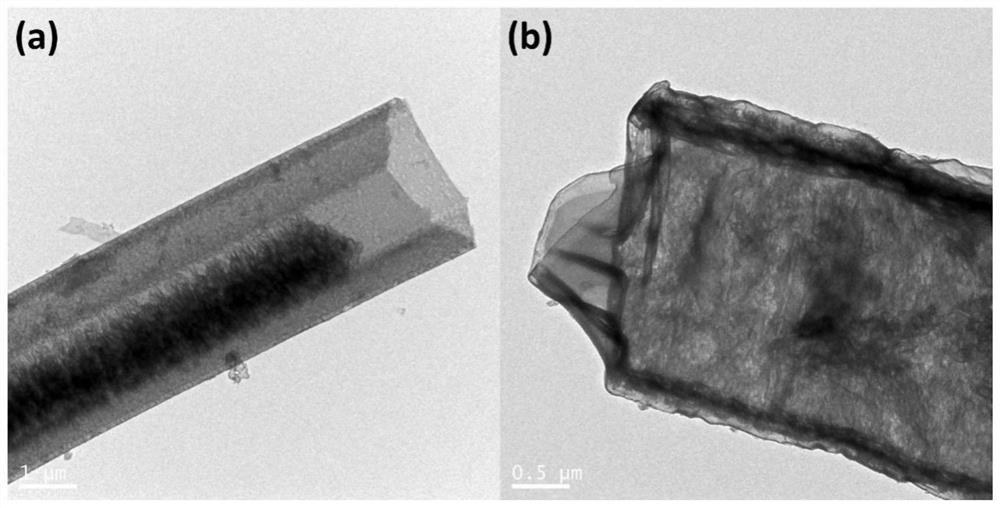

A kind of preparation method and application of manganese oxide composite carbon nitride composite photocatalyst

ActiveCN113042084BLarge specific surface areaIncrease profitPhysical/chemical process catalystsWater/sewage treatment by irradiationNanoreactorSuperoxide radical

The invention provides a method for preparing manganese oxide composite carbon nitride nanotubes, using melamine as a precursor, and preparing carbon nitride nanotubes through a hydrothermal-calcination two-step method; Manganese oxide composite carbon nitride nanotube photocatalytic nanoreactor was prepared by deposition method. The composite photocatalytic nanoreactor has been proved to have good photoelectric performance by a series of characterization means, which is attributed to the modification of manganese oxide not only to improve the absorption of visible light by the nanoreactor, but also as the oxidation activity on the carbon nitride nanoreactor. The sites are enriched for photogenerated holes. The nanoreactor reacts with superoxide radicals (·O 2 ‑ ) and photogenerated holes as the main active oxidants to degrade target organic pollutants. The nanoreactor still maintained 80% of its photocatalytic oxidation performance after 5 cycles. The nano reactor has the advantages of high efficiency, stability and no secondary pollution. Exhibited excellent antibiotic degradation efficiency.

Owner:EAST CHINA UNIV OF SCI & TECH

A micro-nano magnetoelectric coupling device based on ferroelectric thin film and self-assembled magnetic nanoparticle structure

InactiveCN105789432BSimple production processSuitable for controllable integrated productionSolid-state devicesGalvano-magnetic device detailsMicro nanoFerroelectric thin films

Aiming at the problem that high-performance micro-nano magnetoelectric coupling devices are not easy to be controllably prepared, the present invention proposes a patterned +Z and -Z ferroelectric domain processing of ferroelectric thin films through piezoelectric force response microscopy technology, and then through The photochemical deposition method polarizes self-assembled magnetic metal nanoparticles on the surface of ferroelectric domains, and prepares a magnetoelectric coupling device with ferroelectric film and self-assembled magnetic nanoparticle structure. The device includes a ferroelectric thin film layer, a conductive substrate supporting the ferroelectric thin film, and a magnetic nanoparticle structure formed by self-assembly on the ferroelectric thin film layer. The invention utilizes the piezoelectric force response microscopy technology to process PZT ferroelectric domains at the micro-nano level according to the polarization distribution of any pattern, and self-assembles the magnetic metal nanoparticle structure through the photochemical deposition method. The production process is simple, and it is suitable for micro-nano magnetoelectric coupling devices. Integrated preparation.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

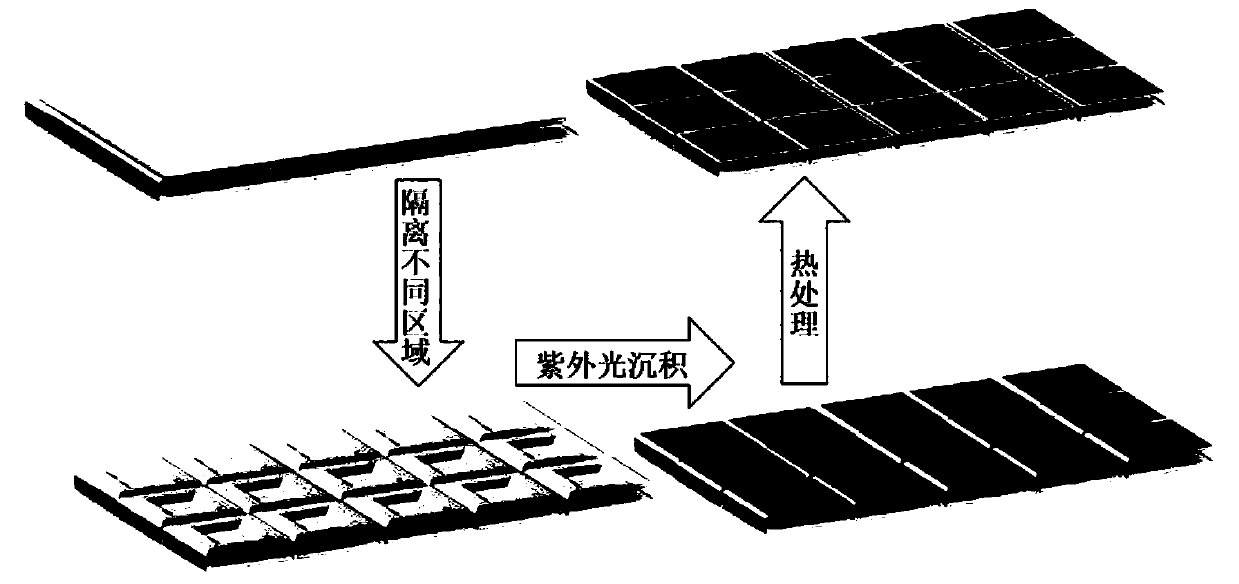

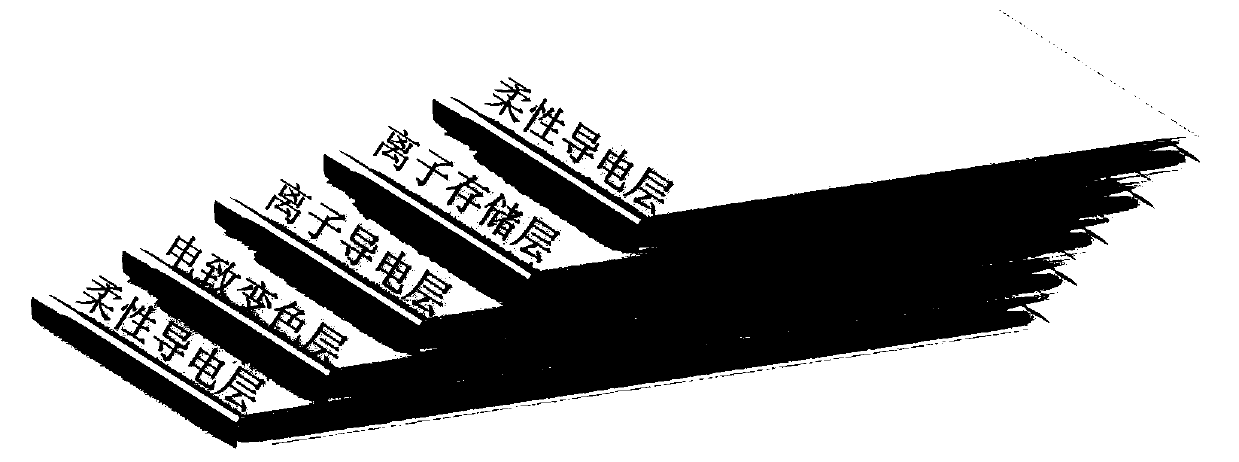

Flexible electrochromic oxide film, flexible electrochromic oxide device and preparation method of flexible electrochromic oxide film

The invention discloses a flexible electrochromic oxide film, a flexible electrochromic oxide device and a preparation method of the flexible electrochromic oxide film. The preparation method of the flexible electrochromic oxide film comprises steps that (1), a plurality of independent areas are isolated on a flexible substrate; (2), halide powder is dissolved in solvent to prepare electrochromicoxide precursor solution, and electrochromic oxide precursor solutions with different concentrations and different types are prepared; (3), one or more electrochromic oxide precursor solutions obtained in the step (2) are dispensed into one or more independent areas isolated in the step (1), then photochemical deposition is performed in an ultraviolet lamp box, and photochemical deposition is repeated for several times; and (4), heat treatment of an oxide film electrode obtained in the step (3) is performed to obtain the flexible electrochromic oxide film. The flexible electrochromic oxide film preparation method has a certain prospect in popularization and application of large-area flexible electrochromic devices.

Owner:NANJING UNIV OF POSTS & TELECOMM

Multifunctional integrated Fe-Al-Ta eutectic composite and preparation method thereof

ActiveCN110904389AIncrease profitExtended service lifeLiquid surface applicatorsChemical vapor deposition coatingMetallurgySpray coating

The invention provides a multifunctional integrated Fe-Al-Ta eutectic composite and a preparation method of the multifunctional integrated Fe-Al-Ta eutectic composite. An electron beam floating zone melting technology, a spray coating technology, a photochemical deposition technology and the like are combined; in the process of preparing the composite, by changing the solidification rate of the Fe-Al-Ta eutectic composite and utilizing the spray coating technology, the photochemical deposition technology and the like, specific machining is conducted on a certain zone of the composite, the zonecan be any shape or pattern, so that the prepared composite has the needed specific performance in the patterned zone, and then the composite integrating multiple functions is prepared. In this way,by combining the three technologies, firstly, the solidification structure of the composite is changed by changing the solidification rates of the different zones, specific machining is conducted on acertain zone by the adoption of the spray coating technology and the photochemical deposition technology according to actual demands, and then the prepared sample integrates multiple functions. The performance of the composite is integrated, concise and diversified, and the comprehensive performance of the composite is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com