Metal-loaded catalytic system for preparing ethylene by photocatalytic oxidation of ethane dehydrogenation and direct ethane dehydrogenation

A photocatalytic oxidation and catalytic system technology, applied in metal/metal oxide/metal hydroxide catalysts, catalysts, carbon compound catalysts, etc., can solve problems such as lowering temperature, unfavorable conversion rate, and easy coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

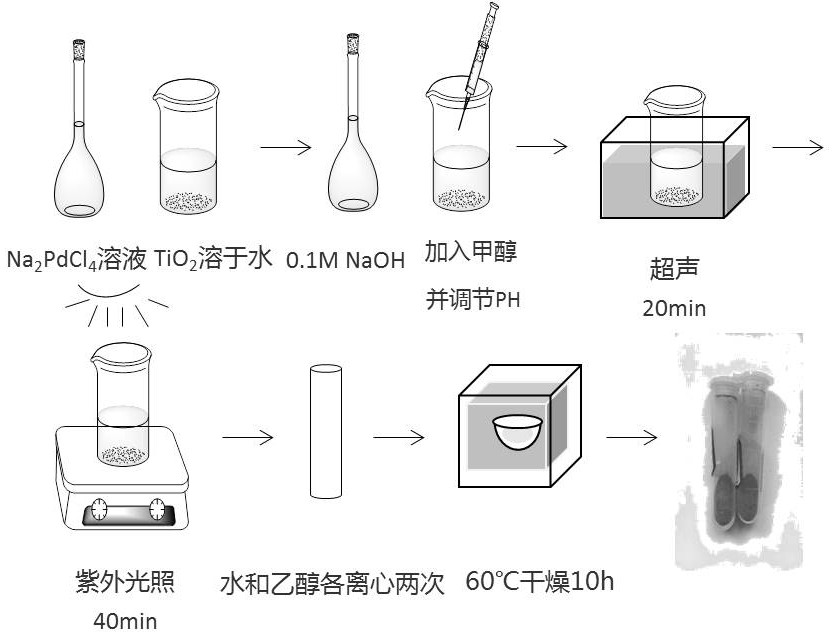

[0025]Example 1: Weigh 0.5g carrier P25 (TiO2) Add to 25ml deionized water, stir until P25 is completely suspended in the water, add 5.025ml prepared 0.5mg / mL Na to the suspension2PdCl4The solution, continue to stir, adjust the pH to pH=10 with 0.1 mol / L NaOH solution, add 5 mL of methanol, disperse ultrasonically for 20 minutes, and reduce by ultraviolet light for 40 minutes. The resulting precipitate is washed with water and ethanol and centrifuged twice. Dry for 10 hours in a vacuum drying oven at 60°C to obtain 0.5%wt-Pd / TiO2catalyst.

Embodiment 2

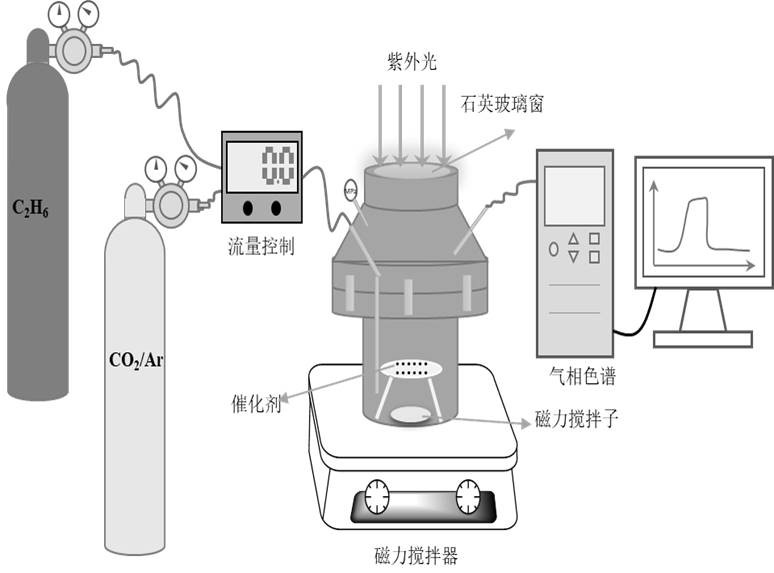

[0026]Example 2: Take 25mg sample and sprinkle it evenly on quartz wool, place the catalyst-sprinkled quartz wool in a 100ml intermittent photocatalytic reactor, seal it, and replace the gas so that there is only CO in the reactor2And C2H6Gas, continue to feed reaction gas until the pressure reaches 0.2 MPa, react for 1 hour under ultraviolet light conditions.

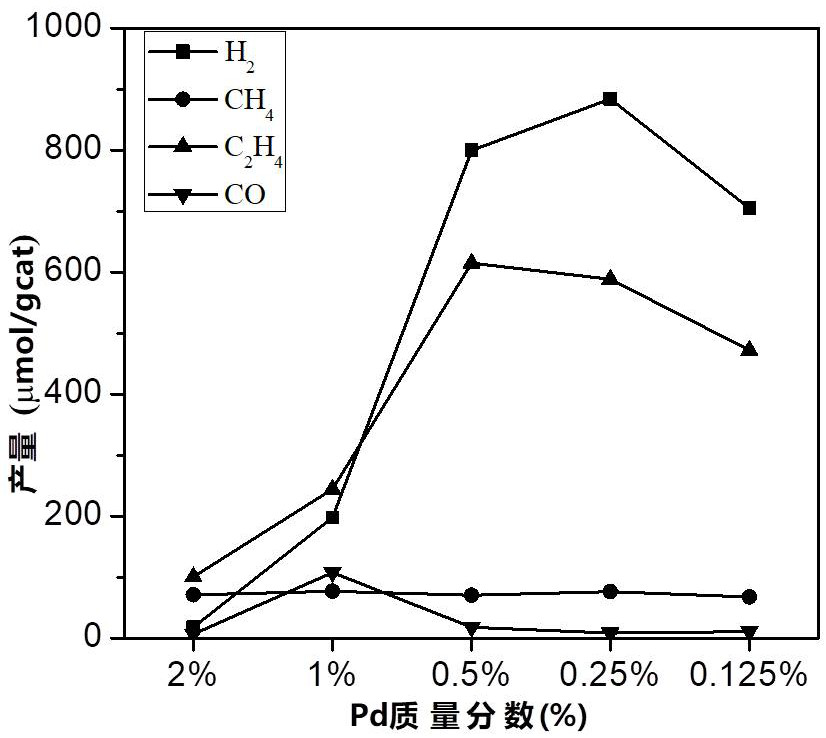

[0027]The yield of the gas product obtained after the reaction was analyzed by Agilent Technologies Inc. type gas chromatography, and the origin mapping software was used for drawing analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com