Bismuth ferrite-graphene compounding magnetism visible light catalyst, as well as preparation method and application of same

A graphene composite and photocatalyst technology applied in the field of visible light catalysis to achieve good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

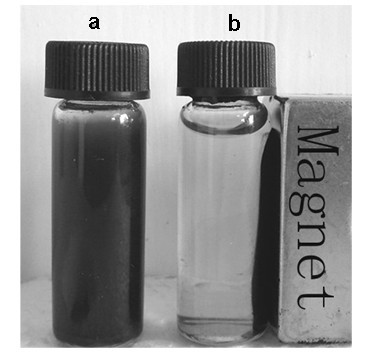

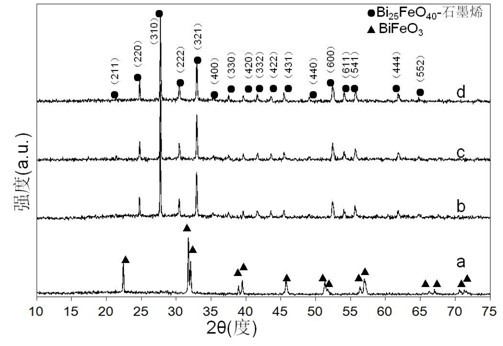

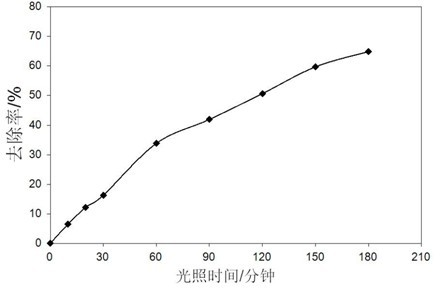

[0028] Example 1: Bi 25 FeO 40 Preparation of -20% graphene

[0029] (1) Use the Hummers method to synthesize graphite oxide. The specific steps are as follows: heat 10ml of concentrated sulfuric acid solution containing 5g of potassium persulfate and 5g of phosphorus pentoxide to 353K, add 10g of graphite powder into it for pre-oxidation for 6h, cool and wash to neutral . Under ice-bath conditions, the obtained material was added to 230ml of concentrated sulfuric acid solution, and then 30g of potassium permanganate was slowly added. Adjust the temperature of the mixed solution to 298K and react for 2 hours, add 1L of deionized water and 25ml of 30% hydrogen peroxide to it, wash and dialyze after the reaction is complete, and ultrasonically disperse the obtained graphite oxide in deionized water;

[0030] (2) Add 5mmol Bi(NO 3 ) 3 and 5mmol Fe(NO 3 ) 3 Dissolve in 1mol / L (10%) nitric acid solution, add 6 mol / L KOH solution dropwise under constant stirring until the ...

Embodiment 2

[0041] Example 2: Bi 25 FeO 40 Preparation of -10% graphene

[0042] In embodiment 2, the add-on of graphite oxide in the catalyst synthesis process is 10%, and its preparation steps are as follows:

[0043] (1) Graphite oxide was synthesized by the Hummers method, and the specific steps were as in step (1) in Example 1;

[0044] (2) Add 5mmol Bi(NO 3 ) 3 and 5mmol Fe(NO 3 ) 3 Dissolve in 1mol / L (10%) nitric acid solution, add 8 mol / L KOH solution dropwise under constant stirring until the solution is alkaline (pH=9);

[0045] (3) Add the graphite oxide prepared in (1) to (2), mix ultrasonically for 50 minutes at 35°C, filter and wash the obtained material, and the amount of graphite oxide added is about 10% of the mass of the composite;

[0046] (4) Add 40ml of 12 mol / L KOH solution and 0.1mol potassium nitrate to (3), stir for 10 minutes, transfer to the reaction kettle 433K for hydrothermal reaction for 24 hours;

[0047] (5) The product obtained in (4) was centr...

Embodiment 3

[0050] Example 3: Bi 25 FeO 40 Preparation of -30% graphene

[0051] In embodiment 3, the add-on of graphite oxide in the catalyst synthesis process is 30%, and its preparation steps are as follows:

[0052] (1) Graphite oxide was synthesized by the Hummers method, and the specific steps were as in step (1) in Example 1;

[0053] (2) Add 5mmol Bi(NO 3 ) 3 and 5mmol Fe(NO 3 ) 3 Dissolve in 1mol / L (10%) nitric acid solution, add 8 mol / L KOH solution dropwise under constant stirring until the solution is alkaline (pH=9);

[0054] (3) Add the graphite oxide prepared in (1) to (2), mix it ultrasonically for 40 minutes, filter and wash the obtained material, and the amount of graphite oxide added is about 30% of the mass of the compound;

[0055] (4) Add 40ml of 12 mol / L KOH solution and 0.1mol potassium nitrate to (3), stir for 10 minutes, transfer to the reaction kettle 433K for hydrothermal reaction for 24 hours;

[0056] (5) The product obtained in (4) was centrifuged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com