Efficient visible-light responsive noble metal-Bi-TiO2 nanometer heterojunction photocatalyst and preparation method thereof

A technology of bi-tio2 and photocatalyst, which is applied in the field of noble metal-Bi-TiO2 nano-heterojunction photocatalyst and its preparation, can solve the limitations of TiO2 photocatalytic technology application, high recombination rate of photogenerated carriers, and solar energy utilization rate Low-level problems, to achieve high visible light catalytic activity, improve photocatalytic efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

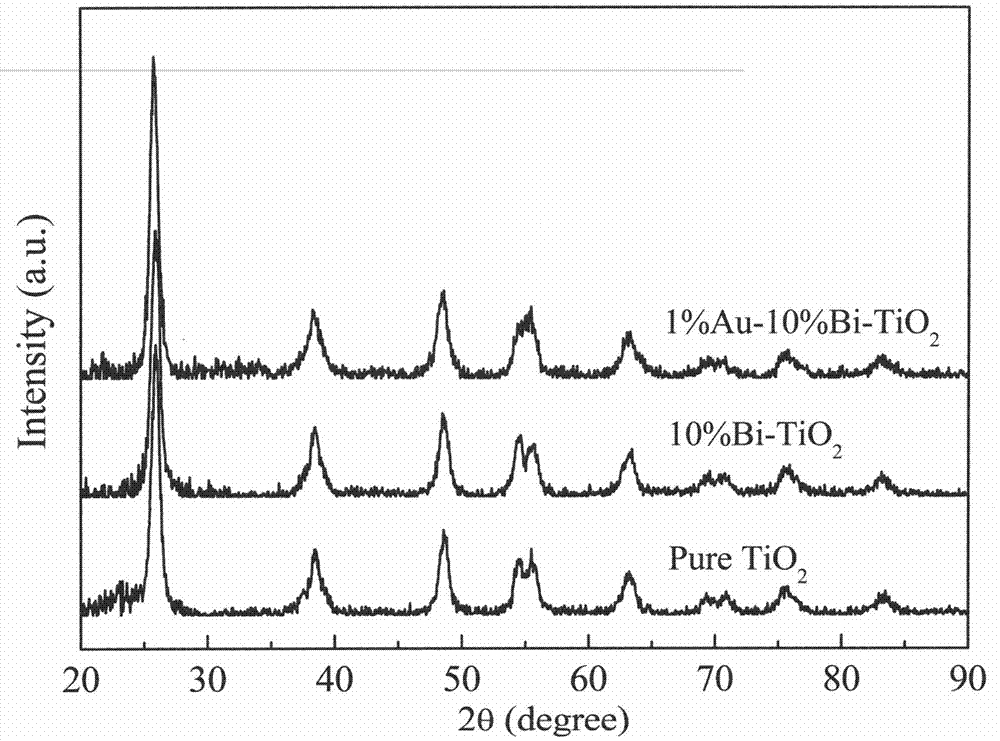

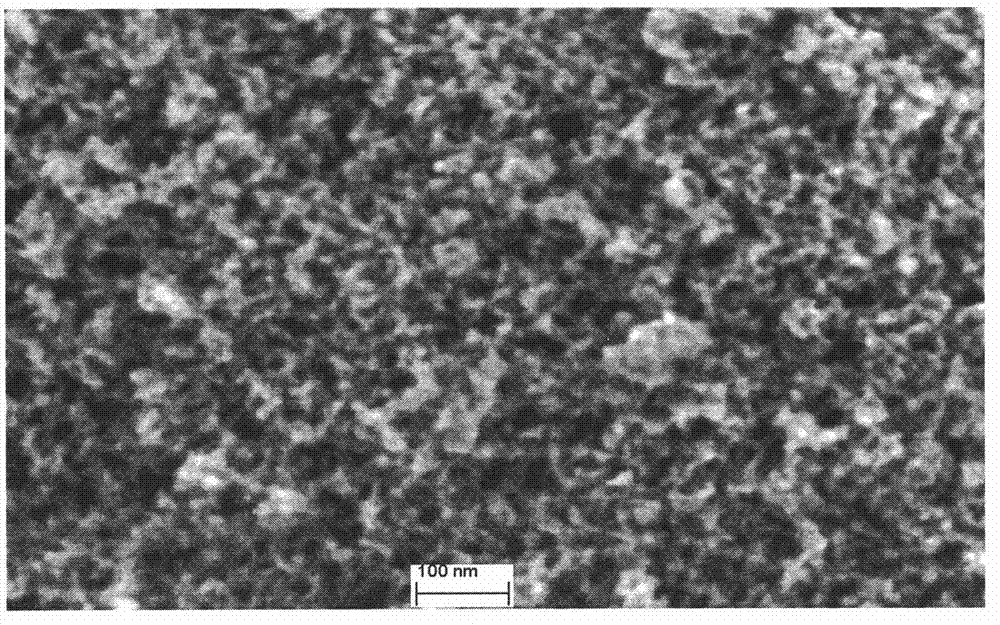

Embodiment 1

[0037] Dissolve butyl titanate in absolute ethanol at a volume ratio of 1:3, and stir to obtain solution A; bismuth nitrate is mixed according to the ratio of bismuth to titanium Bi / (n Ti+ no Bi ) = 10% dissolved in a concentration of 4mol L -1 In the dilute nitric acid solution, a clear solution B was obtained; at a stirring speed of 450rpm, the solution B was added dropwise to the solution A to obtain a Bi / Ti mixed sol; the above sol was transferred to a hydrothermal reaction kettle, and hydrothermal React for 10 hours, cool to room temperature, dry the product in vacuum at 80°C for 8 hours after solid-liquid separation, grind it and roast it at 500°C for 4 hours to obtain bismuth-doped titanium dioxide Bi-TiO 2 , recorded as 10% Bi-TiO 2 ; The prepared Bi-TiO 2 Dispersed at a concentration of 0.02mol L -1 HAuCl 4 A mixed solution is obtained in the solution, so that the mass of the precious metal in the mixed solution is equal to that of Bi-TiO 2 The mass ratio of t...

Embodiment 2

[0040] Dissolve butyl titanate in absolute ethanol at a volume ratio of 1:3, and stir to obtain solution A; bismuth nitrate is mixed according to the ratio of bismuth to titanium Bi / (n Ti+ no Bi ) = 10% dissolved in a concentration of 4mol L -1 In the dilute nitric acid solution, a clear solution B was obtained; at a stirring speed of 450rpm, the solution B was added dropwise to the solution A to obtain a Bi / Ti mixed sol; the above sol was transferred to a hydrothermal reaction kettle, and hydrothermal React for 10 hours, cool to room temperature, dry the product in vacuum at 80°C for 8 hours after solid-liquid separation, grind it and roast it at 500°C for 4 hours to obtain bismuth-doped titanium dioxide Bi-TiO 2 , recorded as 10% Bi-TiO 2 ; The prepared Bi-TiO 2 Dispersed at a concentration of 0.02mol L -1 H 2 PtCl 6 A mixed solution is obtained in the solution, so that the mass of the precious metal in the mixed solution is equal to that of Bi-TiO 2 The mass ratio ...

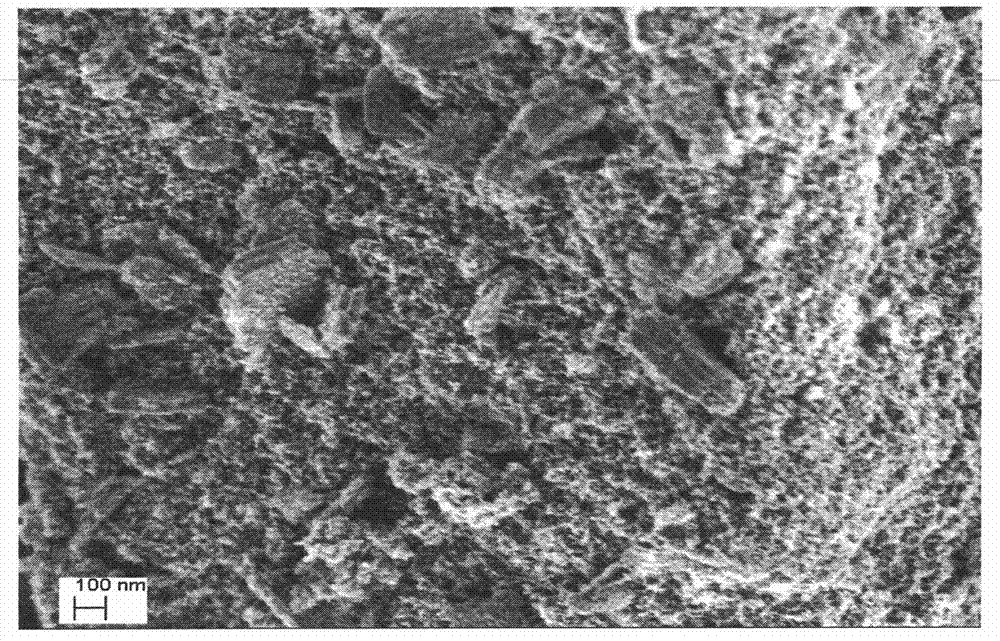

Embodiment 3

[0043] Dissolve butyl titanate in absolute ethanol at a volume ratio of 1:8, and stir to obtain solution A; Bi / (n Ti+ no Bi )=15% dissolved in a concentration of 6mol L -1 In the dilute nitric acid solution, a clear solution B was obtained; at a stirring speed of 400rpm, the solution B was added dropwise to the solution A to obtain a Bi / Ti mixed sol; the above sol was transferred to a hydrothermal reactor, and hydrothermal React for 4 hours, cool to room temperature, dry the product in vacuum at 60°C for 10 hours after solid-liquid separation, grind it and roast it at 450°C for 6 hours to obtain bismuth-doped titanium dioxide Bi-TiO 2 , denoted as 15% Bi-TiO 2 ; The prepared Bi-TiO 2 Dispersed at a concentration of 0.01mol L -1 HAuCl 4 A mixed solution is obtained in the solution, so that the mass of the precious metal in the mixed solution is equal to that of Bi-TiO 2 The mass ratio of the above mixed solution is 0.1%. Stir the above mixed solution in the dark for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com