Composite structure silicon-based germanium quantum dot material and preparation method and application thereof

A composite structure and quantum dot technology, which is applied in metal material coating process, ion implantation plating, final product manufacturing, etc., can solve the problems of limiting the application of quantum dot materials, low density of quantum dots, complicated process flow, etc., to achieve Improve photoelectric conversion efficiency, simple operation, and improve the effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

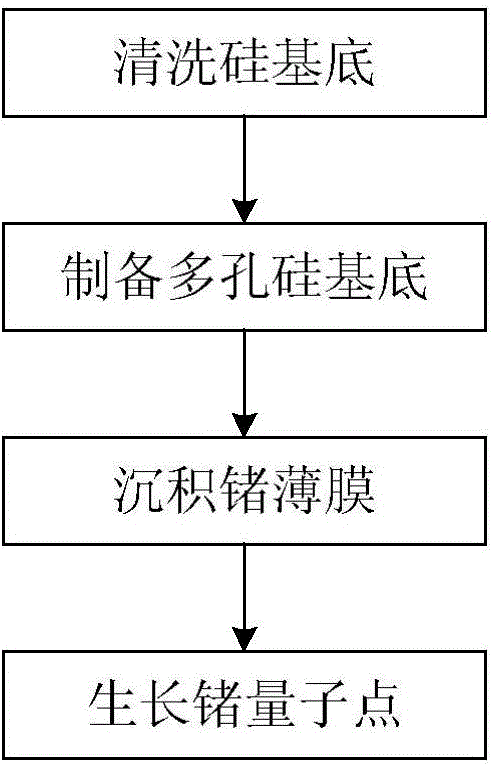

[0077] A method for preparing a silicon-based germanium quantum dot composite structure material comprises the steps of:

[0078] (1) Provide a silicon substrate and carry out the cleaning steps: ultrasonically clean with tap water for 3 minutes, deionized water for 5 minutes, and ethanol and / or acetone for 10 minutes; and repeat the cleaning steps twice to obtain a clean silicon substrate;

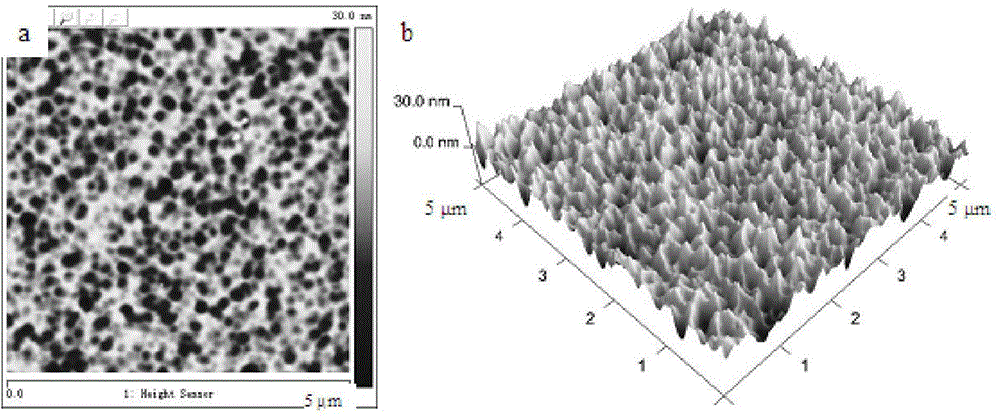

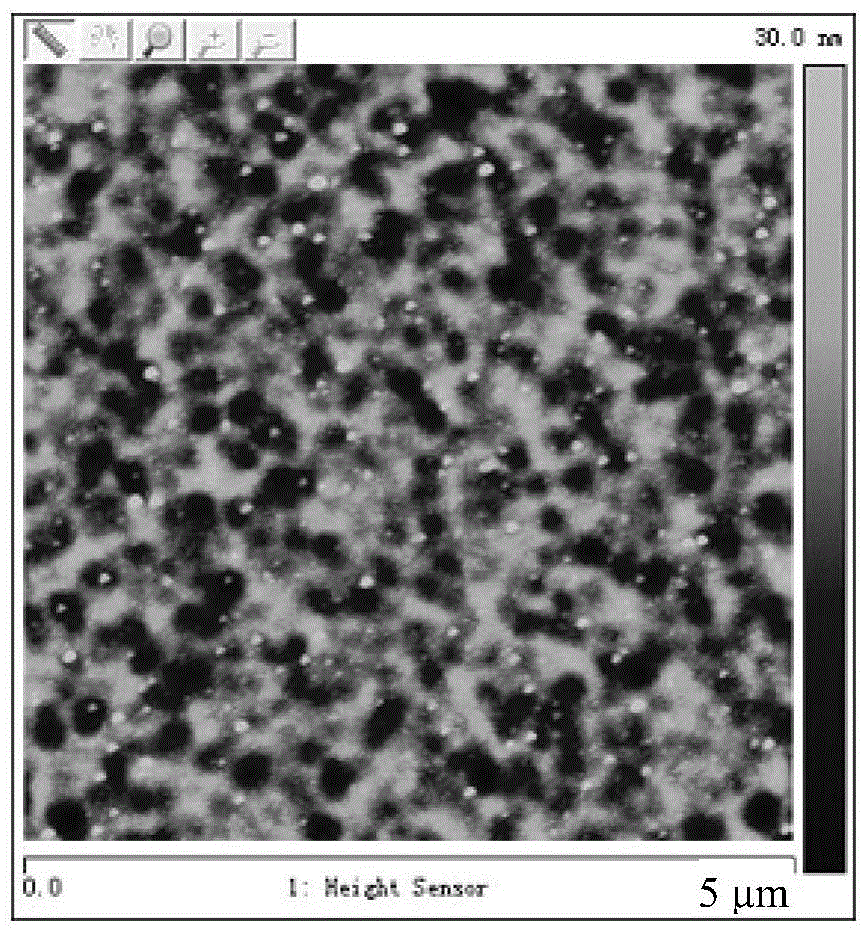

[0079] (2) Place the cleaned silicon substrate in a sodium hydroxide solution with a concentration of 5wt%, apply 30W ultrasonic, and corrode for 70min to prepare a porous silicon substrate; the morphology of the porous silicon substrate is as follows figure 2 ( figure 2It is the AFM image of the porous silicon substrate obtained in step 2 of Example 1, wherein (a) is a plan view; (b) is a perspective view);

[0080] (3) Using the germanium target as the target material, magnetron sputtering is performed, the radio frequency power is 200W, the Ar gas flow rate is 30sccm, and the deposi...

Embodiment 2

[0085] A method for preparing a silicon-based germanium quantum dot composite structure material comprises the steps of:

[0086] (1) Provide a silicon substrate, and carry out the cleaning steps: ultrasonic cleaning with tap water for 5 minutes, ultrasonic cleaning with deionized water for 3 minutes, and ultrasonic cleaning with ethanol and / or acetone for 5 minutes; and repeat the cleaning steps 5 times; obtain a clean silicon substrate;

[0087] (2) Put the cleaned silicon substrate in a sodium hydroxide solution with a concentration of 30wt%, and corrode it for 120 minutes to obtain a prepared porous silicon substrate;

[0088] (3) Using the germanium target as the target material, magnetron sputtering is performed, the radio frequency power is 300W, the Ar gas flow rate is 50sccm, and the deposition time is 60s; a 1nm germanium film is deposited on the porous silicon substrate;

[0089] (4) Anneal the porous silicon substrate deposited with a germanium thin film at 500°C f...

Embodiment 3

[0092] A method for preparing a silicon-based germanium quantum dot composite structure material comprises the steps of:

[0093] (1) Provide a silicon substrate, and perform the cleaning steps: ultrasonic cleaning with tap water for 4 minutes, ultrasonic cleaning with deionized water for 4 minutes, and ultrasonic cleaning with ethanol and / or acetone for 9 minutes; and repeat the cleaning step once; obtain a clean silicon substrate;

[0094] (2) Put the cleaned silicon substrate in a sodium hydroxide solution with a concentration of 20wt%, apply 20W ultrasound, and corrode for 10min to obtain a prepared porous silicon substrate;

[0095] (3) Using a germanium target with a purity of 99.99% as the target material, magnetron sputtering is performed, the radio frequency power is 80W, the Ar gas flow rate is 10sccm, and the deposition time is 1200s; a 15nm germanium film is deposited on the porous silicon substrate;

[0096] (4) Anneal the porous silicon substrate deposited with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com