Preparation method of Ag/alpha-Co(OH)2 oxygen evolution catalyst

A catalyst and oxygen evolution technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of high manufacturing cost, limitation of large-scale production and application, Poor stability and other problems, to achieve the effect of convenient operation, improved catalyst performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1)α-Co(OH) 2 Synthesis of Nanosheets

[0028] In a typical procedure, CoCl 2 ·6H 2 O, NaCl and hexamethylenetetramine (HMT) were sequentially dissolved in 200 mL of deionized water and ethanol at a volume ratio of 9:1 to obtain final concentrations of 10, 50 and 60 mM, respectively. Then the reaction solution was stirred and heated to 90° C. in an oil bath. After heating for about 1 h, a suspension containing green particles resulted. The solid product was collected by centrifugation at 7000 rpm for 2 min, and washed several times with deionized water and absolute ethanol. The final product was air dried at room temperature.

[0029] (2) Ag / α-Co(OH) 2 Synthesis of Nanocomposites

[0030] 50 mg of the above-prepared α-Co(OH) 2 The sample was dispersed in deionized water (40 mL) and ultrasonically dispersed for 5 min. Aqueous silver nitrate (79.5 μL, 10 mg mL -1 ) was configured into 1mL of Ag(NH 3 ) 2 OH solution, and then prepared 1mL of Ag(NH 3 ) 2 OH so...

Embodiment 2

[0039] Ag / α-Co(OH) with different Ag loading content 2 The preparation method of catalyst is substantially the same as that of Example 1, except that silver nitrate aqueous solution (238.5 μ L, 10 mg mL -1 ) was configured into 1 mL of Ag(NH 3 ) 2 OH solution, and the rest of the steps are the same; further characterization analysis and performance testing have been carried out to it, and embodiment 2 can achieve the purpose of the invention.

Embodiment 3

[0041] Ag / α-Co(OH) with different Ag loading content 2 The preparation method of catalyst is substantially the same as that of Example 1, except that silver nitrate aqueous solution (397.5 μ L, 10 mg mL -1 ) was configured into 1 mL of Ag(NH 3 ) 2 OH solution, the rest of the steps are the same; further character analysis and performance testing are carried out, and embodiment 3 can achieve the purpose of the invention.

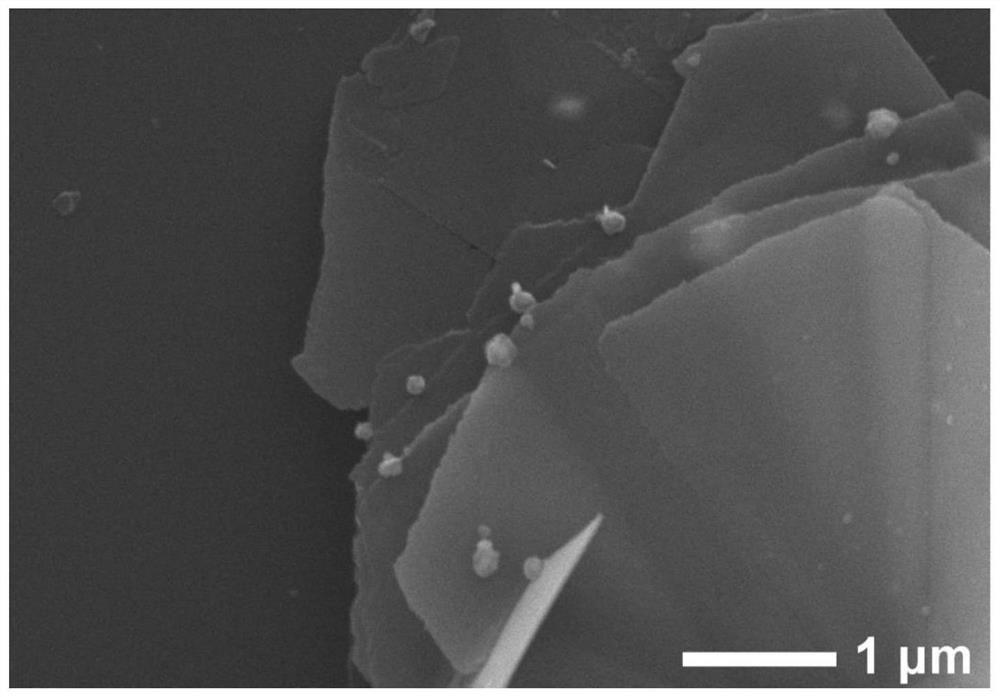

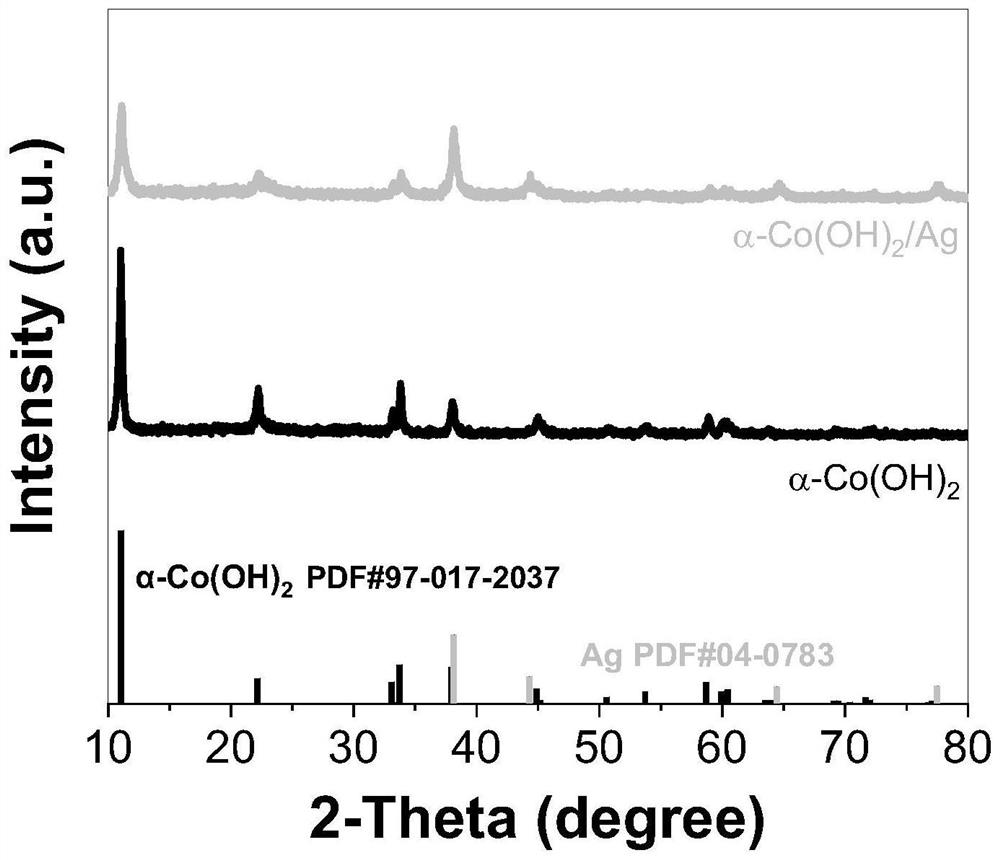

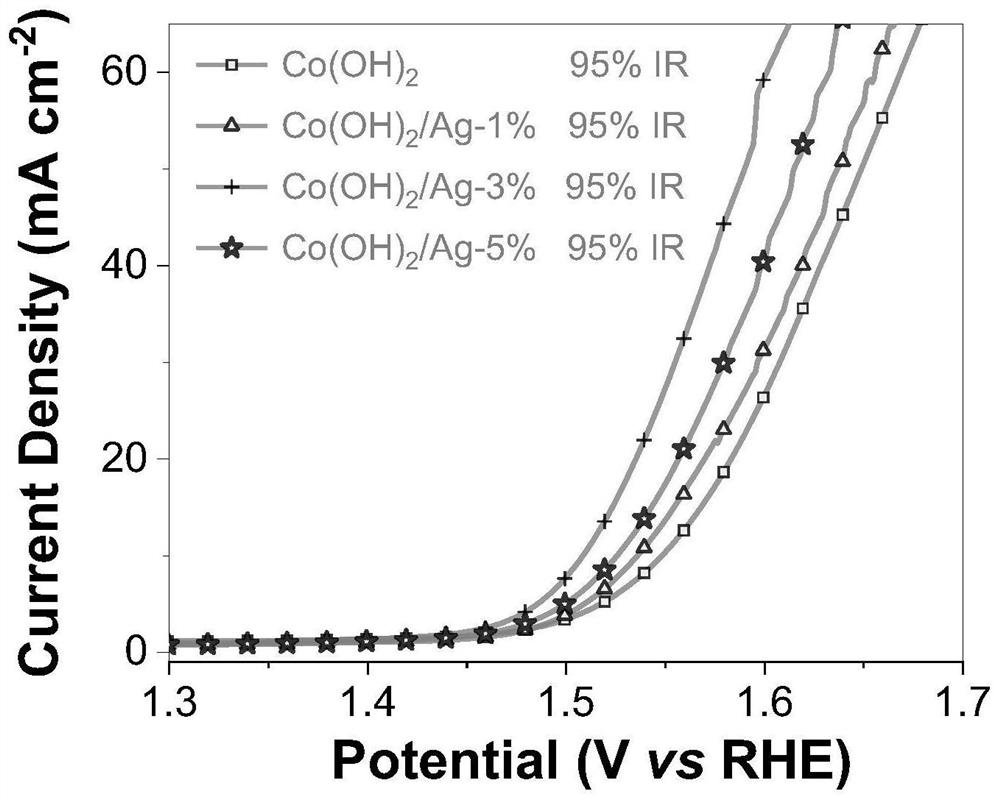

[0042] Test results: Ag / α-Co(OH) with different Ag loading contents were prepared by changing the concentration of added silver ammonia solution 2 The catalyst was subjected to X-ray diffraction and scanning electron microscopy results indicating the successful loading of Ag nanoclusters. A linear voltammetry sweep test was performed on it, such as image 3 Shown, embodiment 2 shows that when the current density is 10mA / cm -2 , the prepared Ag-supported Ag / α-Co(OH) 2 The overpotential of catalyst is reduced to 278mV, embodiment 3 shows that when current...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com