Ag/ZnO hexagonal composite nano sheet as well as preparation method and application thereof

A technology of hexagonal and nanosheets, which is applied in the field of Ag/ZnO hexagonal composite nanosheets and its preparation, can solve the problems of affecting the photocatalytic activity of materials, Ag is easy to agglomerate, etc., and achieve excellent photocatalytic activity and strong visible light absorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In one or more embodiments of the present invention, the specific steps of the preparation method are as follows:

[0032] 1) Dissolve the zinc salt in deionized water, stir and heat until completely dissolved, slowly add 1 mL of hydrazine hydrate dropwise, and react at a constant temperature; wherein, hydrazine hydrate is used as a reducing agent to synthesize hexagonal ZnO nanosheets through chemical bath precipitation;

[0033] 2) After natural cooling, the obtained product is suction filtered, washed and dried to obtain hexagonal ZnO nanosheets.

[0034] 3) Disperse the synthesized hexagonal ZnO nanosheets in a silver nitrate solution and stir for a period of time in the absence of light;

[0035] 4) Under vigorous stirring, the mixture is irradiated with ultraviolet light for a period of time, and the obtained product is suction-filtered, washed, and dried to obtain Ag / ZnO hexagonal composite nanosheets.

[0036] In one or more embodiments of the present invention...

Embodiment 1

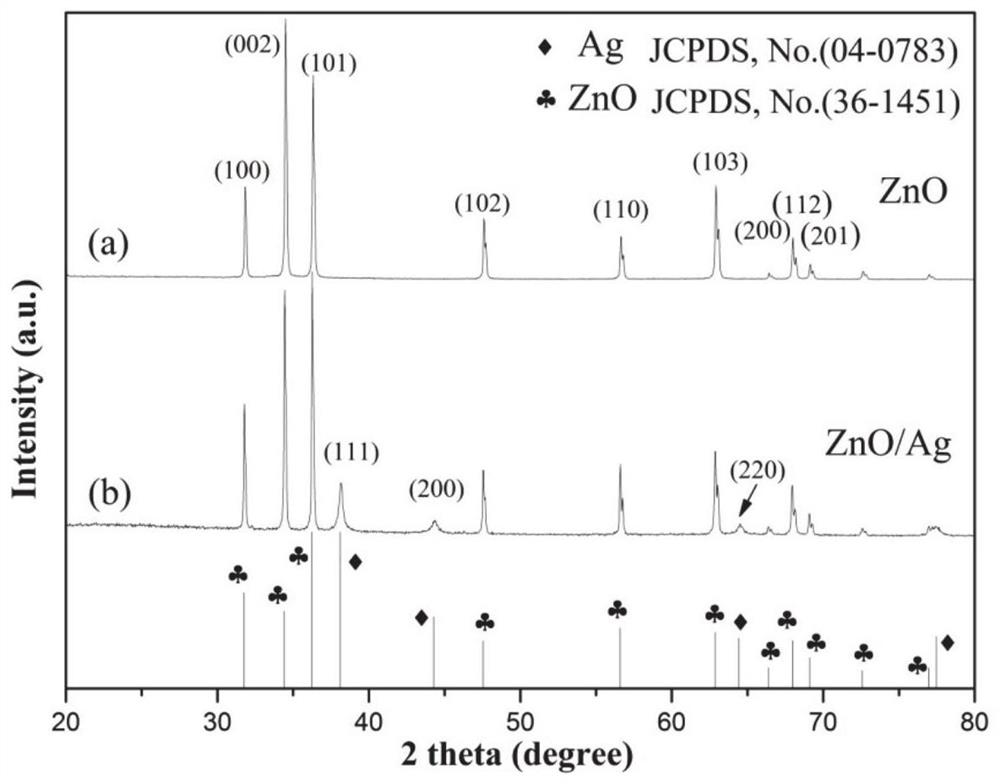

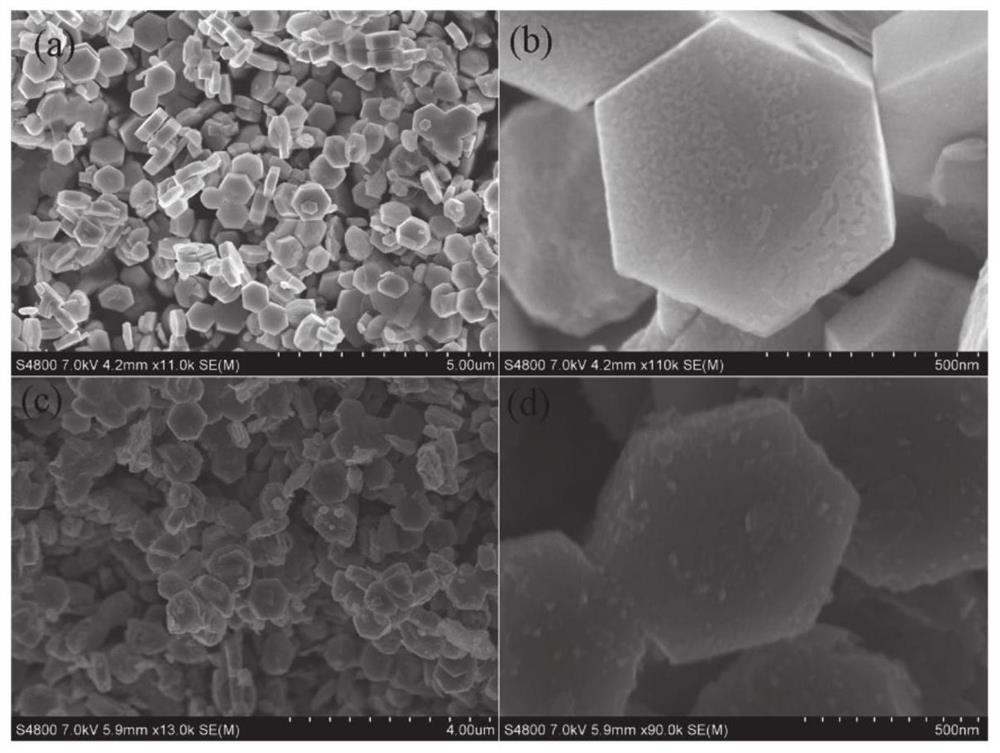

[0047] Dissolve 3.67 g of zinc acetate in 100 mL of deionized water, and heat in an oil bath with magnetic stirring until completely dissolved. When the mixture was heated to 80 °C, 1 mL of hydrazine hydrate was slowly added dropwise into the reactor under vigorous stirring. After constant temperature reaction for 12 h, the white precipitate was filtered, washed several times with absolute ethanol and deionized water, and then dried in an oven at 60° C. for 10 h to synthesize hexagonal ZnO nanosheets. The XRD pattern of the obtained sample is shown in figure 1 As shown in a, it can be seen from the figure that ZnO has a wurtzite structure without impurity peaks. SEM image ( figure 2 a-b) It can be seen that the synthesized hexagonal ZnO nanosheets have regular shape, smooth surface and an average size of 700nm.

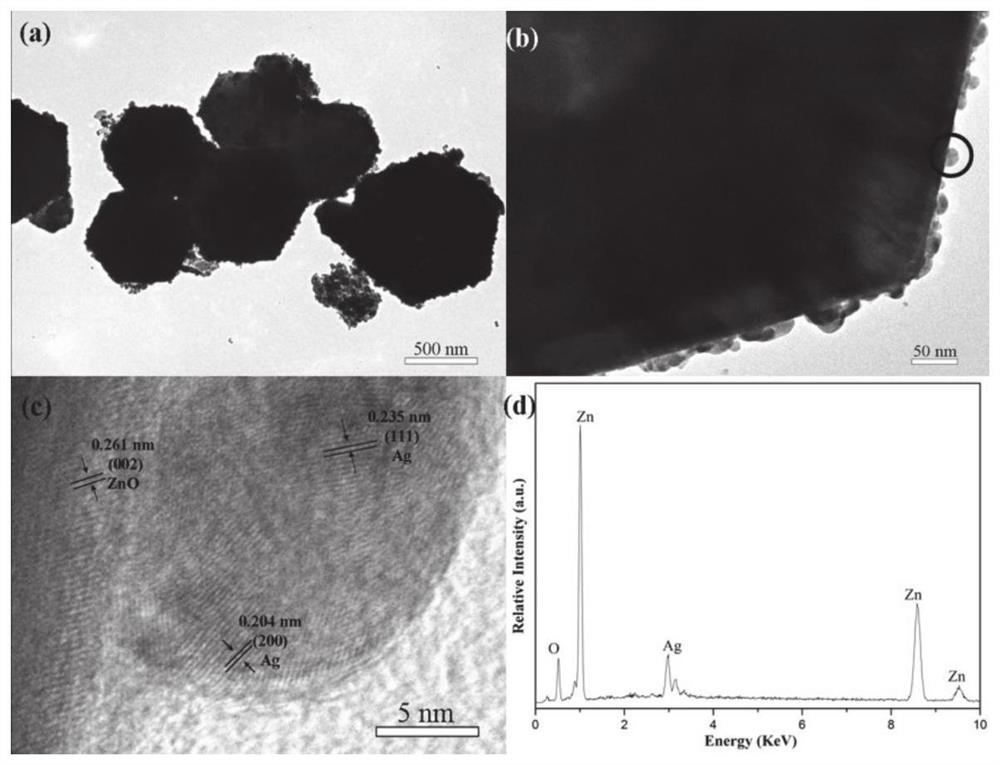

[0048] 0.41 g of silver nitrate was added to 100 mL of deionized water to form a silver nitrate solution, and then 0.24 g of hexagonal ZnO nanosheets were dispers...

Embodiment 2

[0051] Dissolve 3.79 g of zinc nitrate in 100 mL of deionized water, and heat in an oil bath with magnetic stirring until completely dissolved. When the mixture was heated to 90 °C, 1 mL of hydrazine hydrate was slowly added dropwise into the reactor under vigorous stirring. After constant temperature reaction for 12 h, the white precipitate was filtered, washed several times with absolute ethanol and deionized water, and then dried in an oven at 60° C. for 10 h to synthesize hexagonal ZnO nanosheets.

[0052] 0.41 g of silver nitrate was added to 100 mL of deionized water to form a silver nitrate solution, and then 0.24 g of hexagonal ZnO nanosheets were dispersed in the silver nitrate solution. The mixture was stirred for 1.5 h in the dark to allow the Ag + The ions were completely adsorbed on the surface of the hexagonal ZnO nanosheets, and then irradiated for 1 h using a 400W xenon lamp (Beijing Porphylai PLS-SXE300UV) under vigorous stirring. The final product was washe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com