Polythiophene-carbon nitride composite photocatalyst as well as preparation method and application thereof

A technology of polythiophene and carbon nitride, which is applied in the field of photocatalysis, can solve the problems that cannot fully meet the application requirements, high electron-hole recombination efficiency, and poor visible light absorption ability, so as to improve photocatalytic performance, light absorption ability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of polythiophene-carbon nitride composite photocatalyst, its preparation method comprises the following steps:

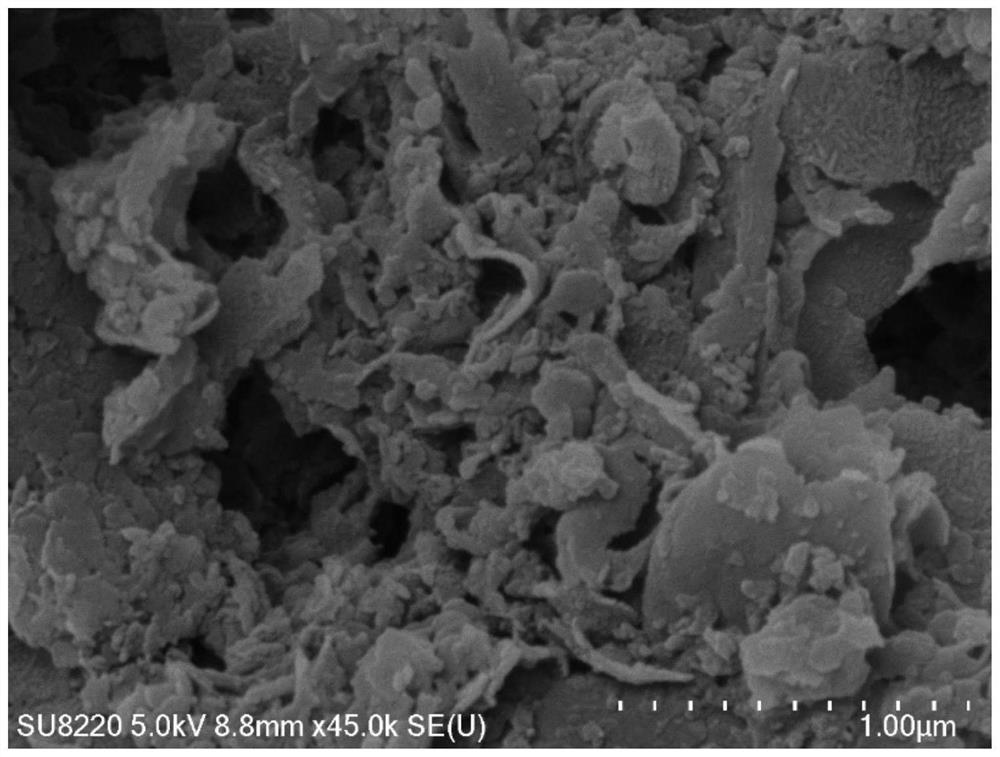

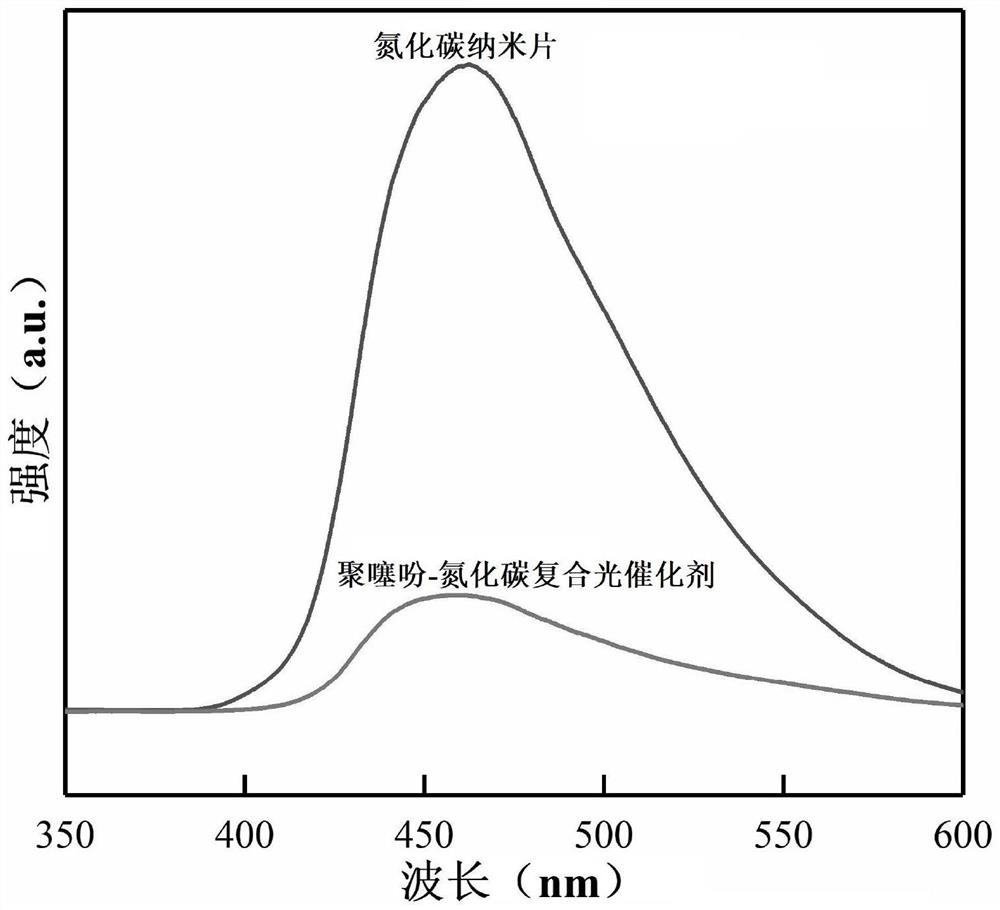

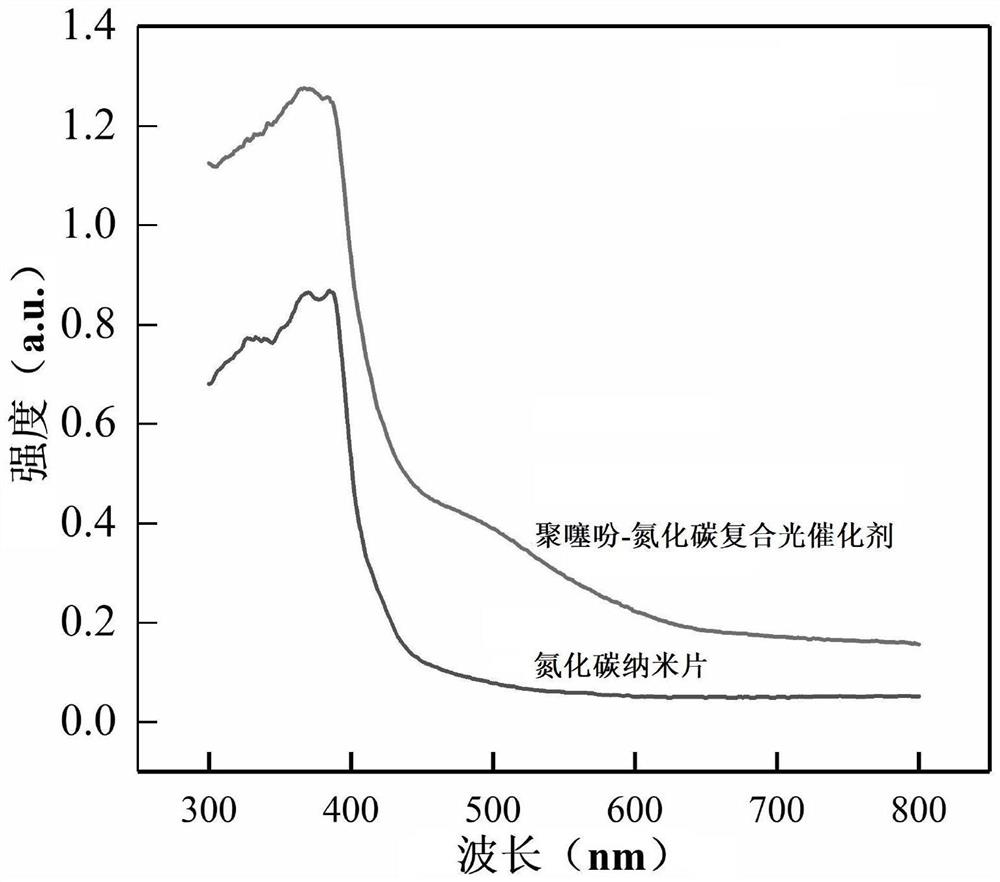

[0044] 1) Add 10.0 g of melamine into the crucible and place it in a muffle furnace, raise the temperature to 550°C at a heating rate of 5°C / min, calcinate at a constant temperature for 4 hours, grind and pass through a 500-mesh sieve, and then obtain the calcined product (block carbon nitride) into the crucible, placed in a muffle furnace, raised to 500°C at a heating rate of 10°C / min, and calcined at a constant temperature for 2 hours to obtain carbon nitride nanosheets;

[0045] 2) Add 1mL of thiophene to 100mL of chloroform, stir evenly, then add 2.800g of ammonium persulfate and fill it with argon for protection, then put it in an oil bath, keep it warm at 60°C for 12h, then wash and centrifuge 3 times with methanol , and then vacuum-dried at 60°C for 12 hours to obtain polythiophene;

[0046] 3) Add 100 mg of polythiophene to 100 mL of tetrahydr...

Embodiment 2

[0058] A kind of polythiophene-carbon nitride composite photocatalyst, its preparation method comprises the following steps:

[0059] 1) Add 10.0 g of melamine into the crucible and place it in a muffle furnace, raise the temperature to 550 °C at a heating rate of 5 °C / min, calcinate at a constant temperature for 4 hours, grind and pass through a 500-mesh sieve, and then obtain the calcined product (block carbon nitride) into the crucible, placed in a muffle furnace, raised to 500°C at a heating rate of 10°C / min, and calcined at a constant temperature for 2 hours to obtain carbon nitride nanosheets;

[0060] 2) Add 1mL of thiophene to 100mL of chloroform, stir evenly, then add 2.800g of ammonium persulfate and fill it with argon for protection, then put it in an oil bath, keep it warm at 60°C for 12h, then wash and centrifuge 3 times with methanol , and then vacuum-dried at 60°C for 12 hours to obtain polythiophene;

[0061] 3) Add 100 mg of polythiophene to 100 mL of tetrahy...

Embodiment 3

[0065] A kind of polythiophene-carbon nitride composite photocatalyst, its preparation method comprises the following steps:

[0066] 1) Add 10.0 g of melamine into the crucible and place it in a muffle furnace, raise the temperature to 550 °C at a heating rate of 5 °C / min, calcinate at a constant temperature for 4 hours, grind and pass through a 500-mesh sieve, and then obtain the calcined product (block carbon nitride) into the crucible, placed in a muffle furnace, raised to 500°C at a heating rate of 10°C / min, and calcined at a constant temperature for 2 hours to obtain carbon nitride nanosheets;

[0067] 2) Add 1mL of thiophene to 100mL of chloroform, stir evenly, then add 2.800g of ammonium persulfate and fill it with argon for protection, then put it in an oil bath, keep it warm at 60°C for 12h, then wash and centrifuge 3 times with methanol , and then vacuum-dried at 60°C for 12 hours to obtain polythiophene;

[0068] 3) Add 100 mg of polythiophene to 100 mL of tetrahy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com