Ti-Au alloy nano-tube photonic crystal electrode with high periodicity and construction method thereof

A technology of alloy nano and photonic crystals, which is applied in nano optics, cleaning methods using liquids, nanotechnology, etc., can solve the problems of nano tube blockage, different sizes, uneven distribution of Au nanoparticles, etc., and achieve photoelectric catalysis Enhanced activity, improved photon efficiency, and reduced recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

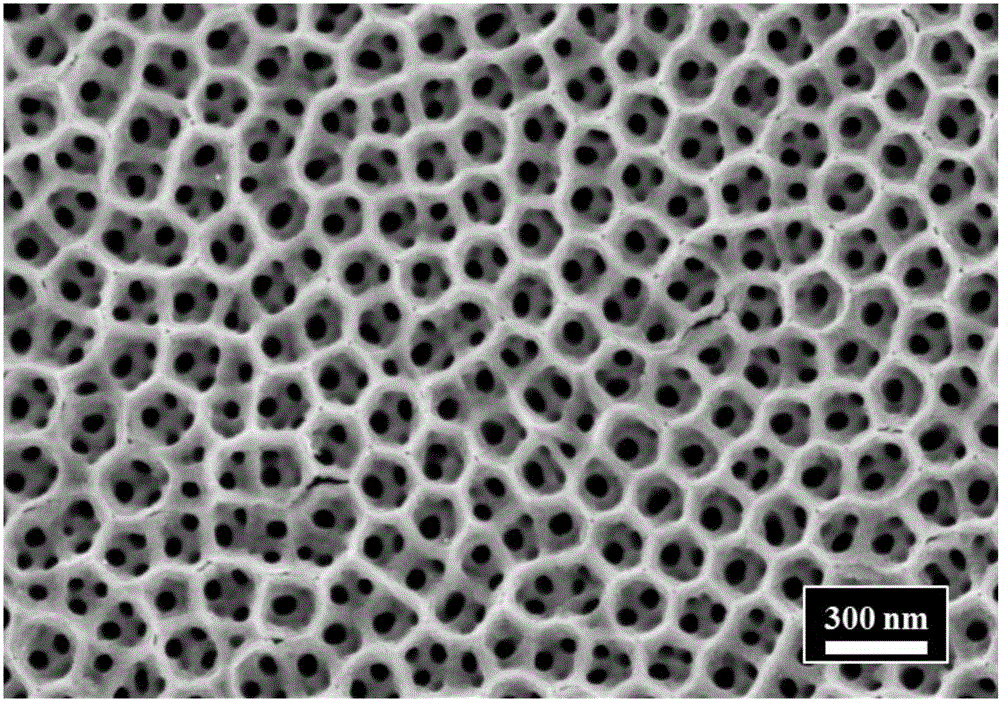

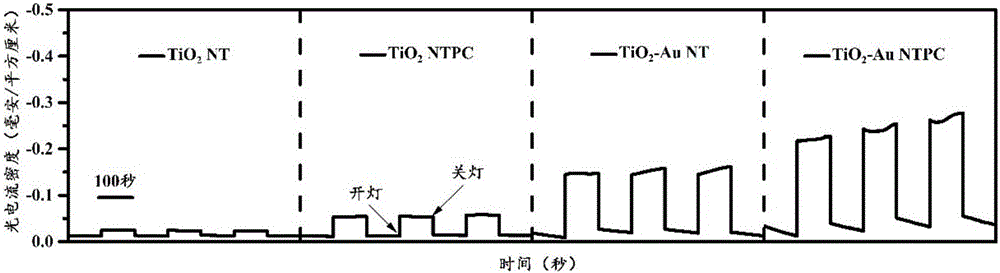

[0038] Before anodizing, the Ti0.2Au (0.2at% Au) alloy plate was polished successively with 180 mesh, 320 mesh, 600 mesh and metallographic sandpaper to make the surface uniform and smooth as a mirror surface, and then successively polished in acetone, ethanol, iso Ultrasonic cleaning with propanol and distilled water for 15 min each, and finally drying under nitrogen atmosphere. Under a constant temperature water bath at 10 °C, the pretreated Ti-Au alloy plate was used as the anode, and the platinum sheet electrode was used as the counter electrode with a distance of 1 cm between the electrodes. -1 HF and 1mol·L -1 H 2The ethylene glycol solution of O was used as the anodizing electrolyte solution, under the action of a constant temperature water bath at 10°C, anodized at a constant voltage of 120V for 3h, and then the prepared nanotubes were ultrasonically treated in deionized water, and the nanotubes were prepared from Ti- The surface of the Au alloy plate was removed, an...

Embodiment 2

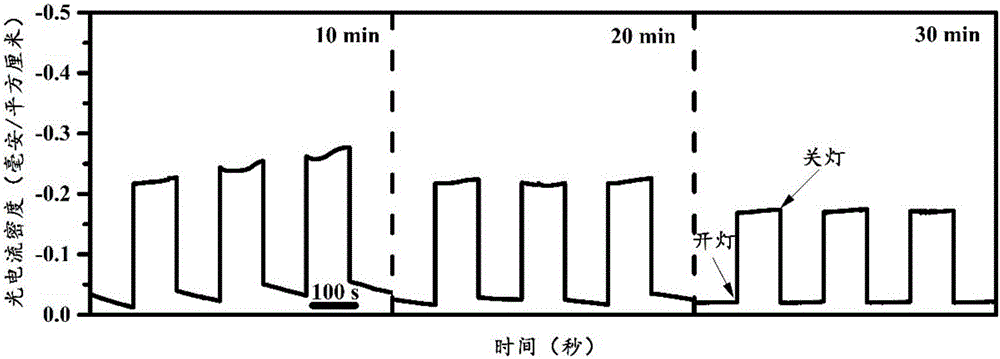

[0041] The pretreatment of the Ti-Au alloy plate and the anodizing electrolyte solution are the same as in Example 1. Under the action of a constant temperature water bath at 10°C, anodize at a constant voltage of 120V for 3 hours, and then ultrasonically treat the prepared nanotubes in deionized water to remove the nanotubes from the surface of the Ti-Au alloy plate, and then the processed The Ti-Au alloy plate was then anodized under constant voltage conditions of 120V for 20min under the action of a constant temperature water bath at 10°C. After the two-step anodization process was completed, the obtained electrode was cleaned with distilled water, soaked in ethanol for 1 h, then dried under a nitrogen atmosphere, and finally placed in a tube furnace for heat treatment in an air atmosphere at 5 °C / min After the heating rate was raised to 450 °C, it was calcined at a constant temperature of 450 °C for 1 h, and finally the temperature was lowered to room temperature at a cool...

Embodiment 3

[0043] The pretreatment of the Ti-Au alloy plate and the anodizing electrolyte solution are the same as in Example 1. Under the action of a constant temperature water bath at 10°C, anodize at a constant voltage of 120V for 3 hours, and then ultrasonically treat the prepared nanotubes in deionized water to remove the nanotubes from the surface of the Ti-Au alloy plate, and then the processed The Ti-Au alloy plate was then anodized under constant voltage conditions of 120V for 30min under the action of a constant temperature water bath at 10°C. After the two-step anodization process was completed, the obtained electrode was cleaned with distilled water, soaked in ethanol for 1 h, then dried under a nitrogen atmosphere, and finally placed in a tube furnace for heat treatment in an air atmosphere at 5 °C / min After the heating rate was raised to 450 °C, it was calcined at a constant temperature of 450 °C for 1 h, and finally the temperature was lowered to room temperature at a cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com