Flexible electrochromic oxide film, flexible electrochromic oxide device and preparation method of flexible electrochromic oxide film

An oxide thin film, electrochromic technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of thick electrochromic film and poor electrochromic performance, achieve strong adhesion, not easy to fall off, and beneficial to Effects of Osmosis and Ion Diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

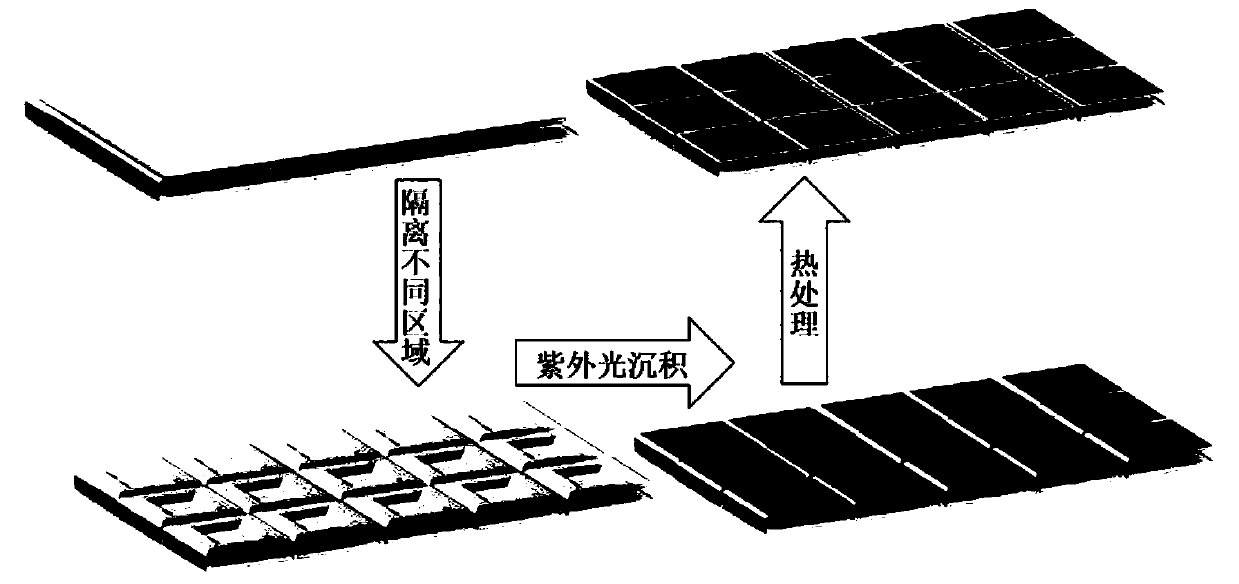

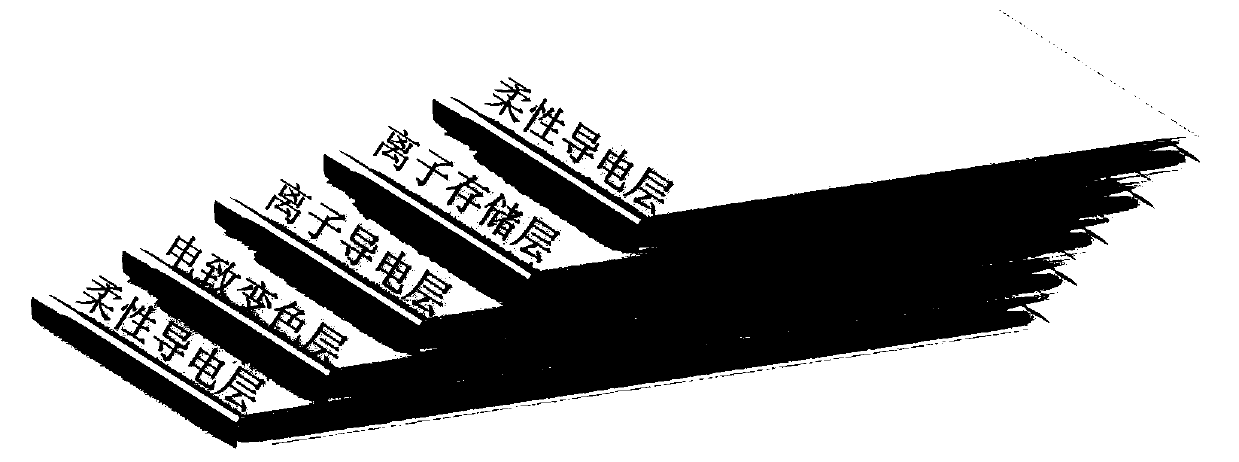

[0039]A preparation method of a flexible electrochromic oxide thin film and a device of the present invention, firstly isolate a plurality of regions on a flexible substrate, and then use ultraviolet light and ozone generated by ultraviolet light to convert transition metal precursors into non-crystalline Based on the principle of transition metal oxides, one or more transition metal oxide films are prepared in different isolation regions, and finally packaged with a flexible counter electrode to form an electrochromic device. Specifically include the following steps:

[0040] (1) Multiple independent regions are isolated on the flexible substrate;

[0041] Among them, the flexible substrate is preferably PET conductive film, PI conductive film, silver-based transparent conductive film, graphene-based transparent conductive film, but not limited thereto;

[0042] Among them, the way of isolating multiple independent regions on the flexible substrate is: the material used for ...

Embodiment 1

[0057] First, the PET flexible substrate with a size of 2×4 cm was ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 10 minutes to remove dust, organic matter and other stains on the surface. Then, the flexible substrate is isolated into two independent regions by using PET, and the material used for isolating the independent regions is adhered to the flexible substrate through an epoxy resin adhesive.

[0058] Prepare a tungsten hexachloride precursor solution with a concentration of 0.25M, weigh 0.4g of tungsten hexachloride powder and dissolve it in 40mL of absolute ethanol, and magnetically stir for 2 hours at room temperature to obtain a uniform dark blue precursor solution.

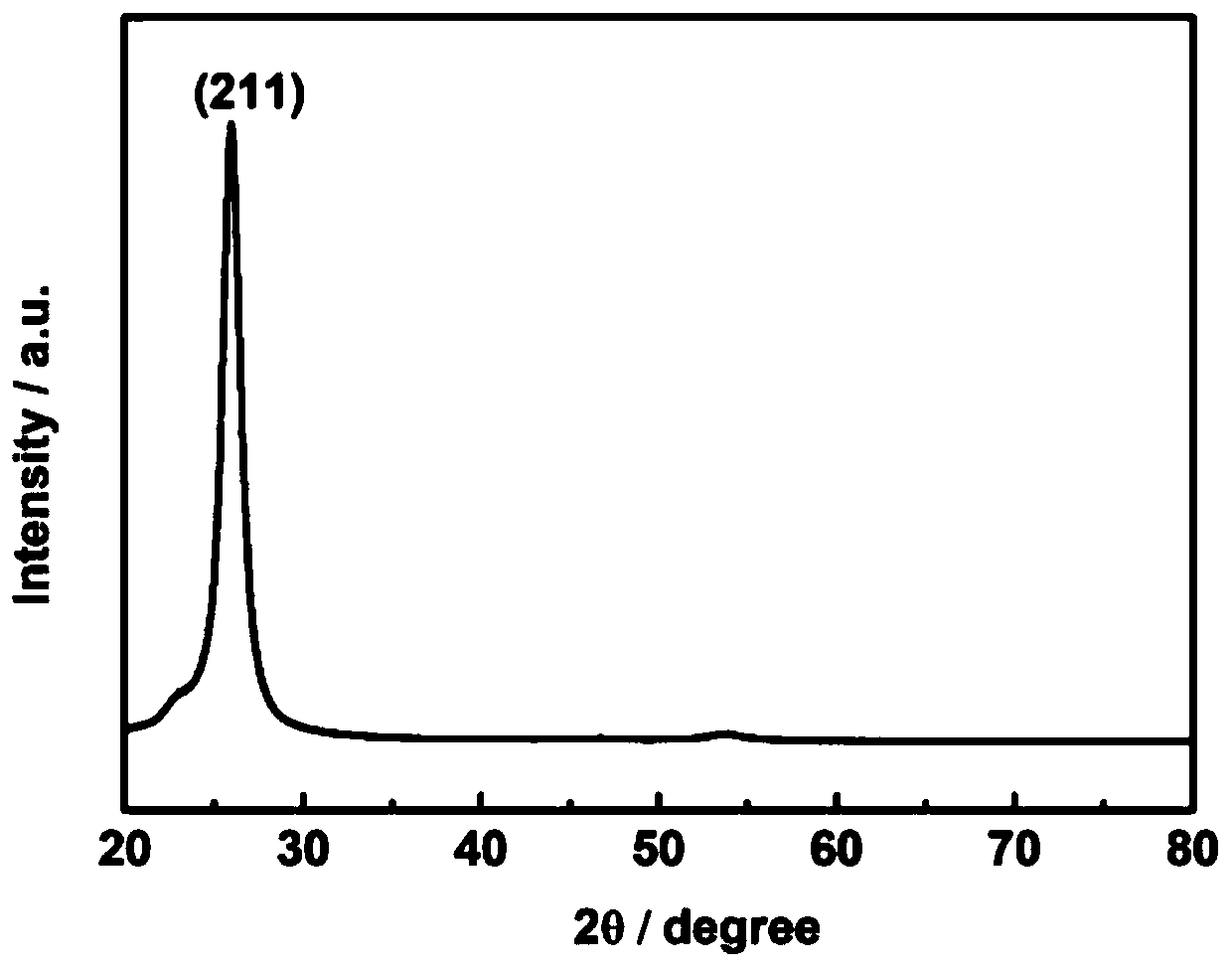

[0059] The tungsten hexachloride precursor solution was drop-coated in two areas separated by PET, and then transferred to a UV light box with a wavelength of 185-254nm, and irradiated by ultraviolet light deposition for 5 minutes. Alternately repeat the steps of drop co...

Embodiment 2

[0063] First, the PET flexible substrate with a size of 2×4 cm was ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 10 minutes to remove dust, organic matter and other stains on the surface. Then, the flexible substrate is isolated into four independent regions by using PET, and the material used for isolating the independent regions is adhered to the flexible substrate through an epoxy resin adhesive.

[0064] Prepare a tungsten hexachloride precursor solution with a concentration of 0.25M, weigh 0.4g of tungsten hexachloride powder and dissolve it in 40mL of absolute ethanol, and magnetically stir for 2 hours at room temperature to obtain a uniform dark blue precursor solution.

[0065] The tungsten hexachloride precursor was drop-coated in four areas separated by PET, and then transferred to a UV light box with a wavelength of 185-254nm, and irradiated by UV light deposition for 10 minutes. Alternately repeat the steps of drip coating and UV li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com