Preparation method for Au-Ag co-modified N-doped ZnO nanorods and application of ZnO nanorods to hydrogen production through photo-electrochemical hydrolysis

A nanorod and co-modification technology, which is applied in the preparation of nitrogen-doped ZnO nanorods and the application field of photoelectrochemical hydrolysis hydrogen production, can solve the problems of harmful surfactants and toxic reaction conditions, and achieve effective electron transfer and simple Synthetic method, good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

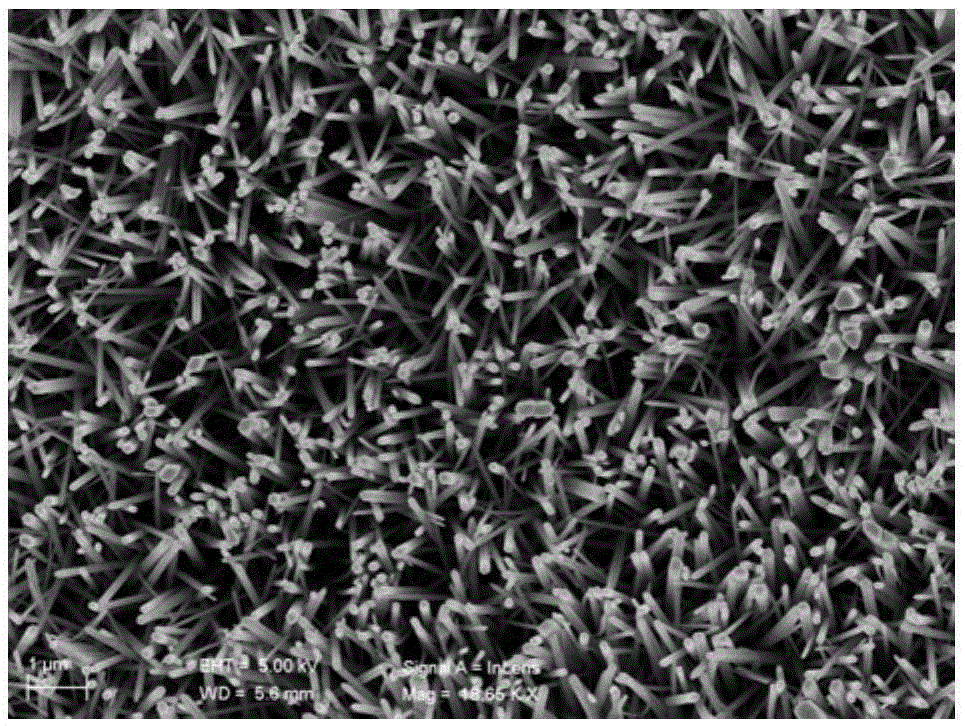

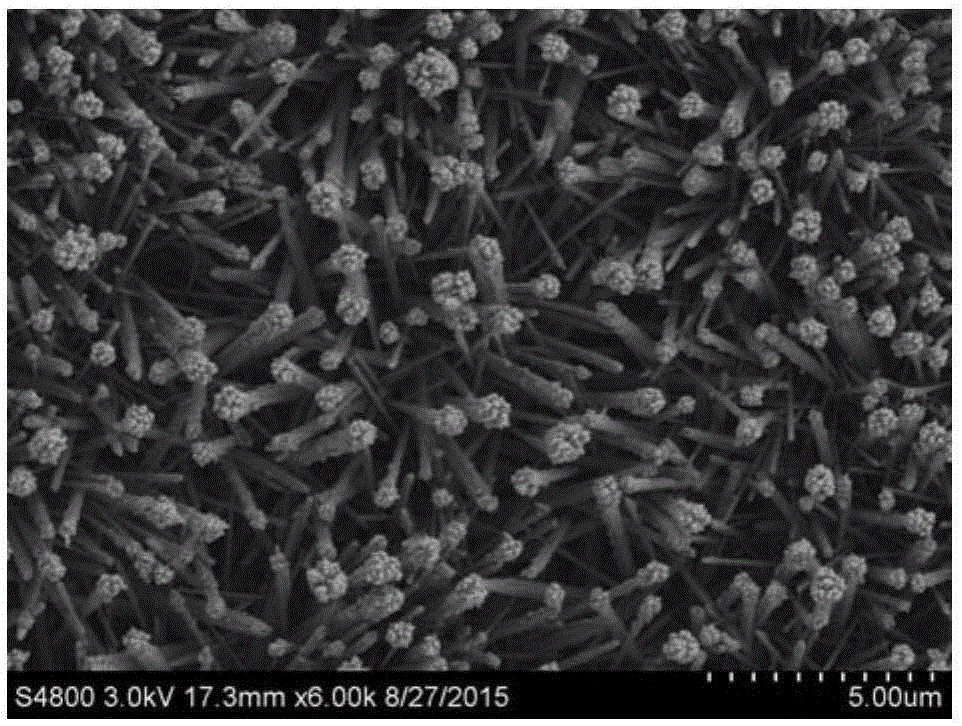

[0055] Polished smooth zinc sheet (1×3cm 2 ) were ultrasonically cleaned in acetone, ethanol, and deionized water for 5 min, and dried in air. Take 1ml of hexamethylenediamine and disperse it in 39ml of deionized water, stir evenly, and transfer it to a 50ml reaction kettle. Dip the cleaned zinc flakes into the above solution, and heat the reactor to 150°C in an oven for 4 hours. The samples were taken out, washed alternately with ethanol and deionized water, placed in a vacuum oven at 60°C, and dried for 5 hours. The vacuum-dried sample was calcined in an ammonia atmosphere, the calcining temperature was 400° C., and the calcining time was 10 min. Next, prepare AgNO with a concentration of 0.01mM 3 Solution, take 50ml and put it in a test tube, put it under the xenon lamp for 6h, take out the sample and wash it alternately with ethanol and deionized water, put it in a vacuum drying oven at 60°C, and dry it for 5h. The final preparation concentration is 0.1mM HAuCl 4 Solu...

Embodiment 2

[0057] Polished smooth zinc sheet (1×3cm 2 ) were ultrasonically cleaned in acetone, ethanol, and deionized water for 5 min, and dried in air. Take 1ml of hexamethylenediamine and disperse it in 39ml of deionized water, stir evenly, and transfer it to a 50ml reaction kettle. Dip the cleaned zinc flakes into the above solution, and heat the reactor to 150°C in an oven for 4 hours. The samples were taken out, washed alternately with ethanol and deionized water, placed in a vacuum oven at 60°C, and dried for 5 hours. The vacuum-dried sample was calcined in an ammonia atmosphere, the calcining temperature was 400° C., and the calcining time was 10 min. Next, prepare AgNO with a concentration of 0.01mM 3 Solution, take 50ml and put it in a test tube, put it under the xenon lamp for 6h, take out the sample and wash it alternately with ethanol and deionized water, put it in a vacuum drying oven at 60°C, and dry it for 5h. The final preparation concentration is 0.1mM HAuCl 4 Solu...

Embodiment 3

[0059] Polished smooth zinc sheet (1×3cm 2 ) were ultrasonically cleaned in acetone, ethanol, and deionized water for 5 min, and dried in air. Take 1ml of hexamethylenediamine and disperse it in 39ml of deionized water, stir evenly, and transfer it to a 50ml reaction kettle. Dip the cleaned zinc flakes into the above solution, and heat the reactor to 150°C in an oven for 4 hours. The samples were taken out, washed alternately with ethanol and deionized water, placed in a vacuum oven at 60°C, and dried for 5 hours. The vacuum-dried sample was calcined in an ammonia atmosphere, the calcining temperature was 400° C., and the calcining time was 10 min. Next, prepare AgNO with a concentration of 0.01mM 3 Solution, take 50ml and put it in a test tube, put it under the xenon lamp for 6h, take out the sample and wash it alternately with ethanol and deionized water, put it in a vacuum drying oven at 60°C, and dry it for 5h. The final preparation concentration is 0.1mM HAuCl 4 Solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com