Silver-titanium dioxide-chitosan composite antibacterial filter material and preparation method thereof

A titanium dioxide and composite antibacterial technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of human injury, high radioactive ultraviolet energy, etc., achieve good antibacterial effect and improve the effect of sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

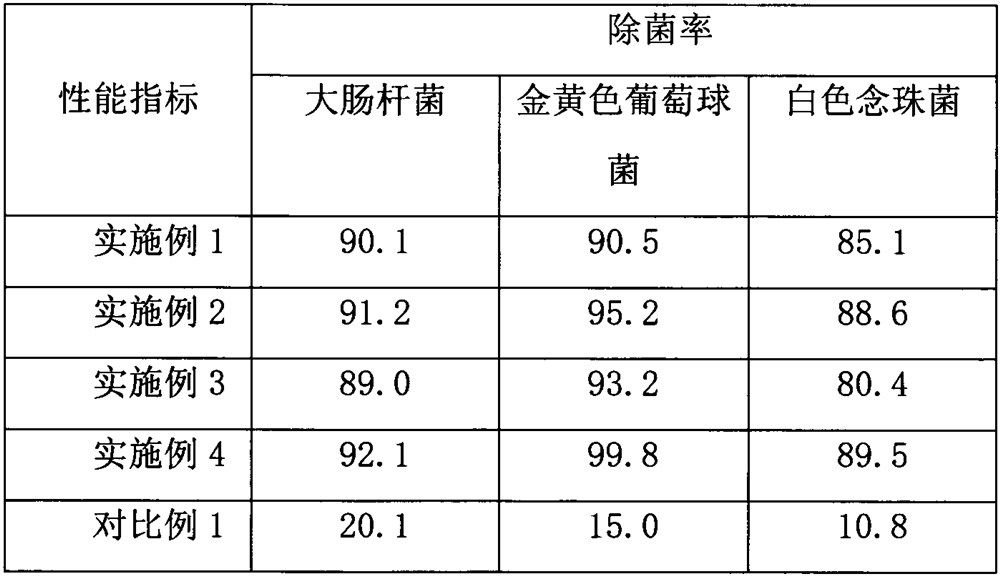

Examples

Embodiment 1

[0030] Dissolve 15g of 80% deacetylated chitosan powder in 50g of 3% formic acid solution, adjust the pH to 2.6, stir continuously at a speed of 100r / min for 12h until completely dissolved, add 15g of titanium dioxide powder, and continue stirring at a speed of 100r / min for 24h to obtain a viscous colloid solution. Add 25% glutaraldehyde solution into the viscous colloid solution, stir and react at 100r / min for 24h, add 0.5mol· -1 L sodium hydroxide solution was driven by a peristaltic pump to form hydrogel beads, the hydrogel beads were collected, washed with deionized water, and dried at 90° C. for 12 hours to obtain titanium dioxide-chitosan hydrogel beads. Add 15g of zero-valent nano-silver particles and 85g of titanium dioxide-chitosan hydrogel beads into the photochemical reactor, adjust the wavelength of ultraviolet light to 350nm, and react for 6h in a nitrogen-protected environment. It was washed with deionized water and dried at 120°C for 10 hours to obtain a silver...

Embodiment 2

[0035] Dissolve 20g of 80% deacetylated chitosan powder in 60g of 3% acetic acid solution, adjust the pH to 2.6, stir continuously at a speed of 100r / min for 12h until completely dissolved, add 20g of titanium dioxide powder, and continue stirring at a speed of 100r / min for 24h to obtain a viscous colloidal solution. Add 25% glutaraldehyde solution into the viscous colloid solution, stir and react at 100r / min for 24h, add 0.5mol· -1 L sodium hydroxide solution was driven by a peristaltic pump to form hydrogel beads, the hydrogel beads were collected, washed with deionized water, and dried at 90° C. for 12 hours to obtain titanium dioxide-chitosan hydrogel beads. Add 20g of zero-valent nano-silver particles and 80g of titanium dioxide-chitosan hydrogel beads into the photochemical reactor, adjust the wavelength of ultraviolet light to 350nm, and react for 6h in a nitrogen-protected environment. It was washed with deionized water and dried at 120°C for 10 hours to obtain a silv...

Embodiment 3

[0038] Dissolve 20g of 80% deacetylated chitosan powder in 60g of 5% formic acid solution, adjust the pH to 2.8, stir continuously at a speed of 100r / min for 12h until completely dissolved, add 15g of titanium dioxide powder, and continue stirring at a speed of 100r / min for 24h to obtain a viscous colloid solution. Add 30% glutaraldehyde solution into the viscous colloid solution, stir and react at 100r / min for 24h, add 0.5mol· -1 L sodium hydroxide solution was driven by a peristaltic pump to form hydrogel beads, the hydrogel beads were collected, washed with deionized water, and dried at 90° C. for 12 hours to obtain titanium dioxide-chitosan hydrogel beads. Add 15g of zero-valent nano-silver particles and 90g of titanium dioxide-chitosan hydrogel beads into the photochemical reactor, adjust the wavelength of ultraviolet light to 350nm, and react for 6h in a nitrogen-protected environment. It was washed with deionized water and dried at 120°C for 10 hours to obtain a silver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com