Method for preparing cadmium-sulfide nano film based on deep ultraviolet photochemical bath deposition

A deep-ultraviolet light, nano-film technology, applied in cadmium sulfide, photovoltaic power generation, electrical components, etc., can solve the problems of unsuitable solar cell technology, uncontrollable, complicated process, etc., to achieve controllable film deposition rate and stable properties , the effect of accelerating the deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

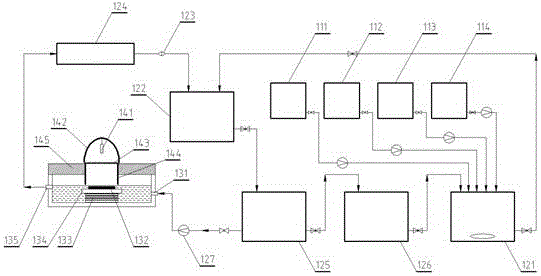

[0048] This embodiment provides a process device for preparing a cadmium sulfide nano-film in an LED deep ultraviolet photochemical water bath, see figure 1 , including deposition liquid supply system, deep ultraviolet photochemical reaction device and deep ultraviolet light source system. The deposition solution supply system includes four mutually independent source solution containers, cadmium sulfate source solution tank 111, sodium thiosulfate source solution tank 112, sodium sulfite source solution tank 113, and dilute sulfuric acid tank 114, which are mixed with solutions through pipelines and peristaltic pumps respectively Pond 121 is connected, can control the ratio of each source solution flow rate control mixed solution; The liquid port communicates with the upper liquid outlet of the sedimentation tank 124, and a filter 123 is arranged in the middle, and the liquid outlet of the regeneration tank 122 communicates with the liquid inlet of the feed pool 125 through a...

Embodiment 2

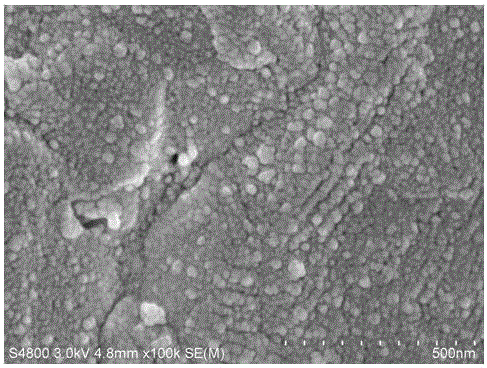

[0053] In this embodiment, ITO glass is used as the substrate, soaked in acetone, ethanol and deionized water in sequence, cleaned by ultrasonic waves, and dried with compressed air for use.

[0054] S1. Set the concentration to 8.0×10 -3 mol / L of CdSO 4 solution, 0.4 mol / L Na 2 S 2 o 3 Solution, 2×10 -3 mol / L Na 2 SO 3 solution and 0.09mol / L dilute H 2 SO 4 The solutions are respectively stored in four independent containers of the source solution supply device, and the peristaltic pump is turned on so that the four source solutions are input according to the flow rates of 0.05L / min, 0.05L / min, 0.05L / min, and 0.05L / min respectively. In the solution mixing device, set the speed of the mixer to 1000rpm to fully mix the four solutions; at the same time, observe the readings of the pH sensor and the concentration of the material, and adjust the dilute H in time. 2 SO 4 The flow rate of the solution and the supplied raw material keeps the pH value of the mixed solution i...

Embodiment 3

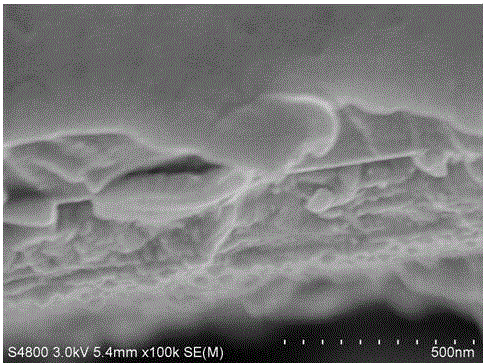

[0060] In this embodiment, molybdenum glass coated with a CIGS absorbing layer was selected as the substrate, soaked in thiourea solution for 10 minutes, rinsed with water and ethanol, and dried with nitrogen gas for later use.

[0061] S1. Set the concentration to 8.0×10 -3 mol / L of CdSO 4 solution, 0.4 mol / L Na 2 S 2 o 3 Solution, 1.6×10 - 3 mol / L Na 2 SO 3 solution and 0.09 dilute H 2 SO 4 The solutions are respectively stored in four independent containers of the source solution supply device, and the peristaltic pump is turned on so that the four source solutions are input according to the flow rates of 0.05L / min, 0.05L / min, 0.05L / min, and 0.05L / min respectively. In the solution mixing device, set the speed of the mixer to 1000rpm to fully mix the four solutions; at the same time, observe the readings of the pH sensor and the concentration of the material, and adjust the dilute H in time. 2 SO 4 The flow rate of the solution and the supplied raw material keeps ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com