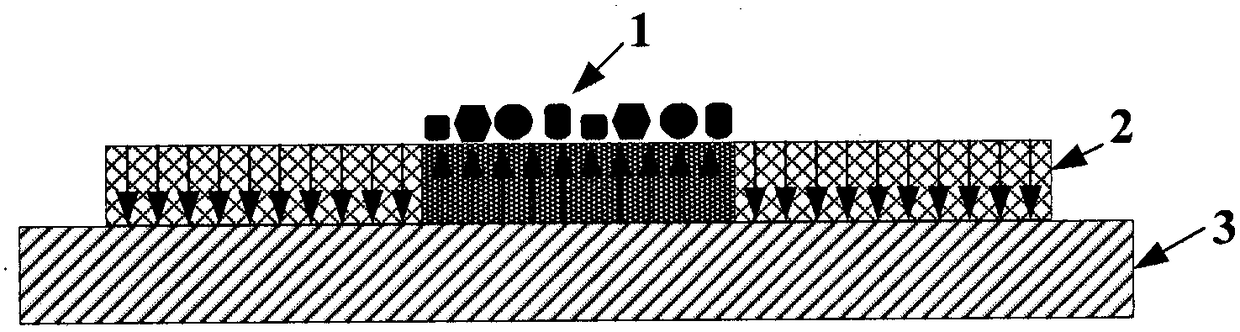

A micro-nano magnetoelectric coupling device based on ferroelectric thin film and self-assembled magnetic nanoparticle structure

A technology of magnetic nanoparticles and ferroelectric thin films, which is applied to devices applying electro-magnetic effects, parts of electromagnetic equipment, and electric solid devices, etc. It can solve complex processes, difficult integration preparation, and influence on the performance of magnetoelectric materials, etc. problem, to achieve the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

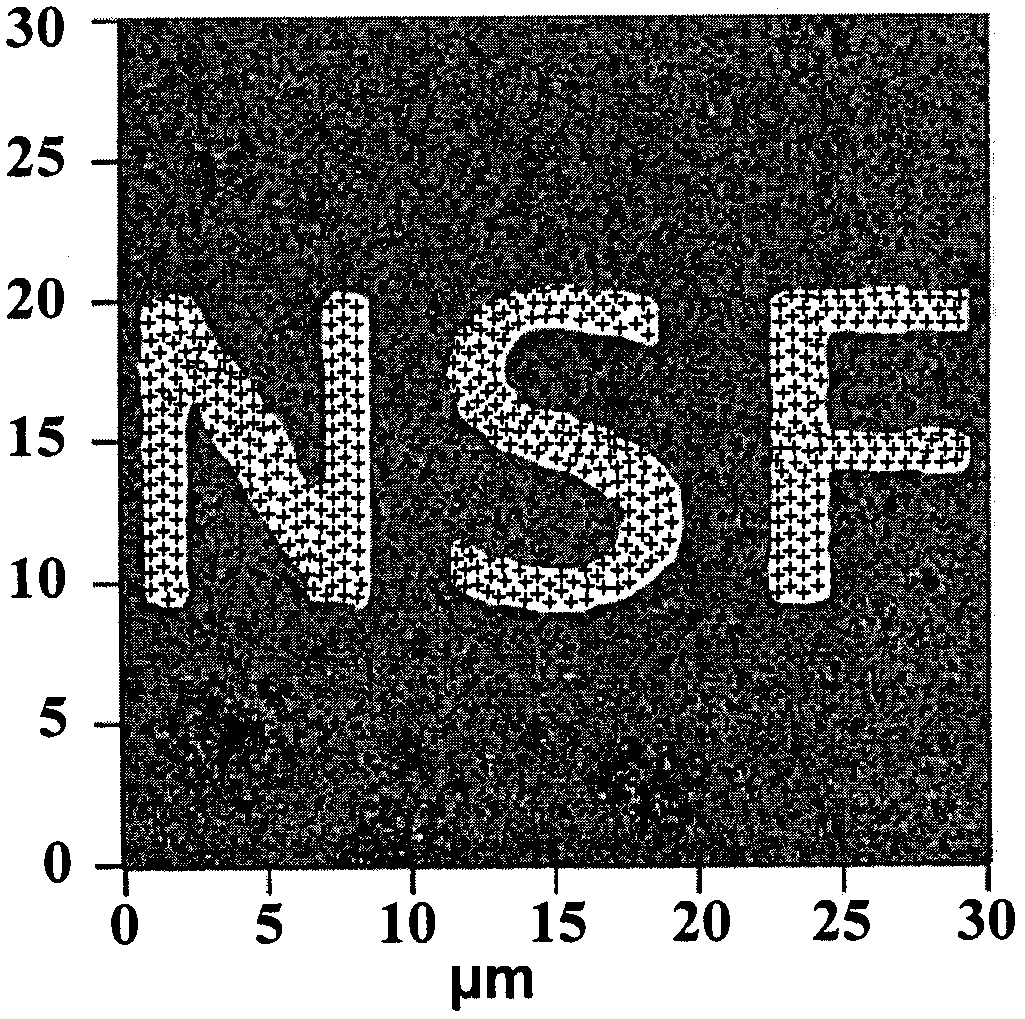

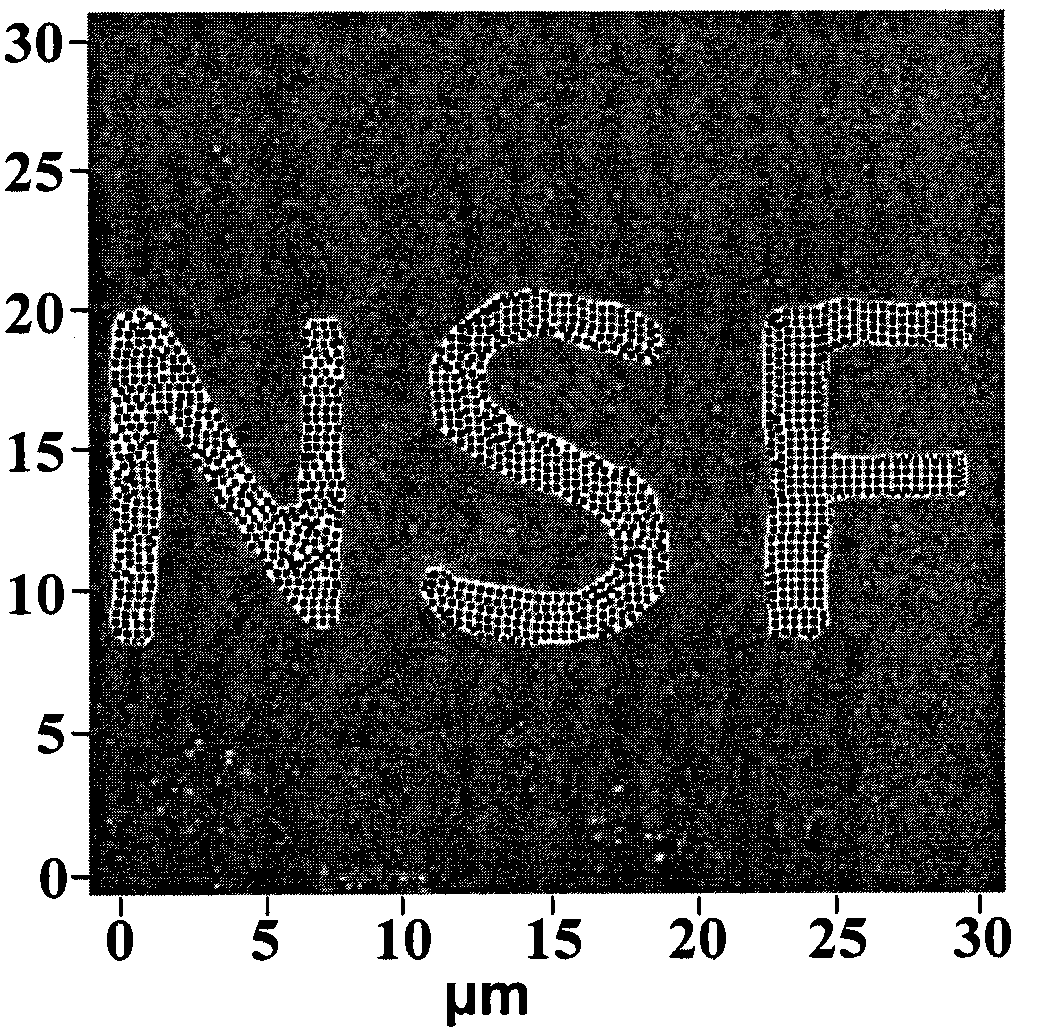

[0018] The ferroelectric film is made of lead zirconate titanate film, and the substrate is Pt / Ti / SiO 2 / Si(100) substrate, the magnetic metal chloride is nickel dichloride. Using lead acetate, tetrabutyl titanate and zirconium nitrate as the ion source of lead zirconate titanate, according to the chemical formula Pb(Zr 0.53 Ti 0.47 )O 3 And add 5% more lead acetate (to compensate for the volatilization loss of lead in the PZT wet film during the annealing process) to prepare a 2mol / L precursor solution sol. Dissolve lead acetate trihydrate and zirconium nitrate pentahydrate in ethylene glycol monomethyl ether solvent, and stir for 1 hour at 90°C. The stabilizer acetylacetone (the molar ratio to Zr is 1:2) was added to the above solution, and stirred at 80° C. for 30 minutes. Add tetrabutyl titanate to the prepared Pb and Zr mixture, stir at 80°C for 1 hour, then add 0.4% formamide to adjust the viscosity, and filter with filter paper after cooling to obtain the PZT precur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com