Method for preparing CIGS film based on photochemistry deposition

A photochemical deposition, copper indium gallium selenide technology, applied in the fields of optoelectronic materials and new energy, can solve problems such as low cost, and achieve the effects of low equipment requirements, good appearance, and uniform film layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

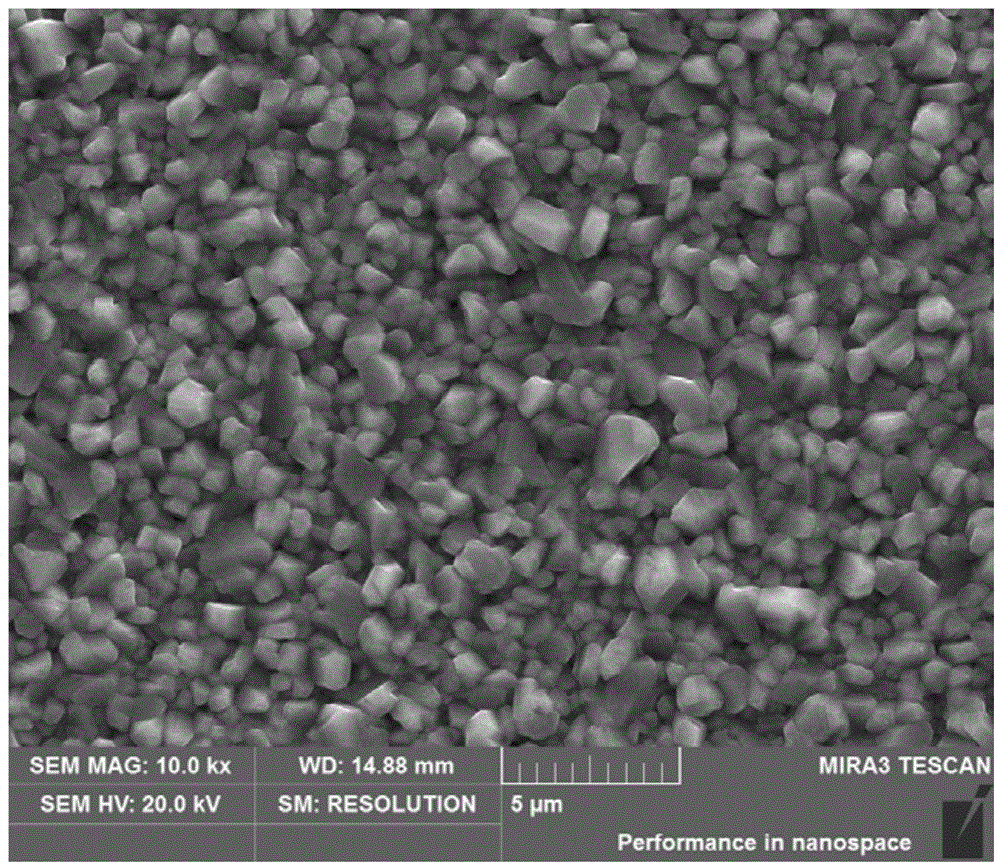

[0037] Se was plated on the Mo glass substrate with a thickness of 700nm by laser pulse deposition process. The solute composition of the reaction solution is 0.02mol / L CuCl 2 , 0.01mol / L InCl 3 , 0.01mol / L SeO 2 , 0.01mol / L GaCl 3 , 0.75mol / L K 2 S 2 o 3 , adjust the pH to 7.0 with dilute hydrochloric acid or sodium hydroxide; adopt the following photochemical deposition parameters: the incident light is a monochromatic light source of 400nm (the light intensity is 150mW / cm 2 ), the solution temperature was 40°C, and the deposition time was 90 minutes. Copper indium gallium selenide thin film Cu is deposited on the surface of the substrate with a thickness of 1-2 μm a In b Ga c Se d , and finally the film was placed in Se-containing argon, and heat-treated at a temperature of 580° C. for 40 minutes. image 3 It is the XRD pattern before and after the annealing of the copper indium gallium selenium thin film prepared in embodiment 3.

[0038] from image 3 It can ...

Embodiment 2

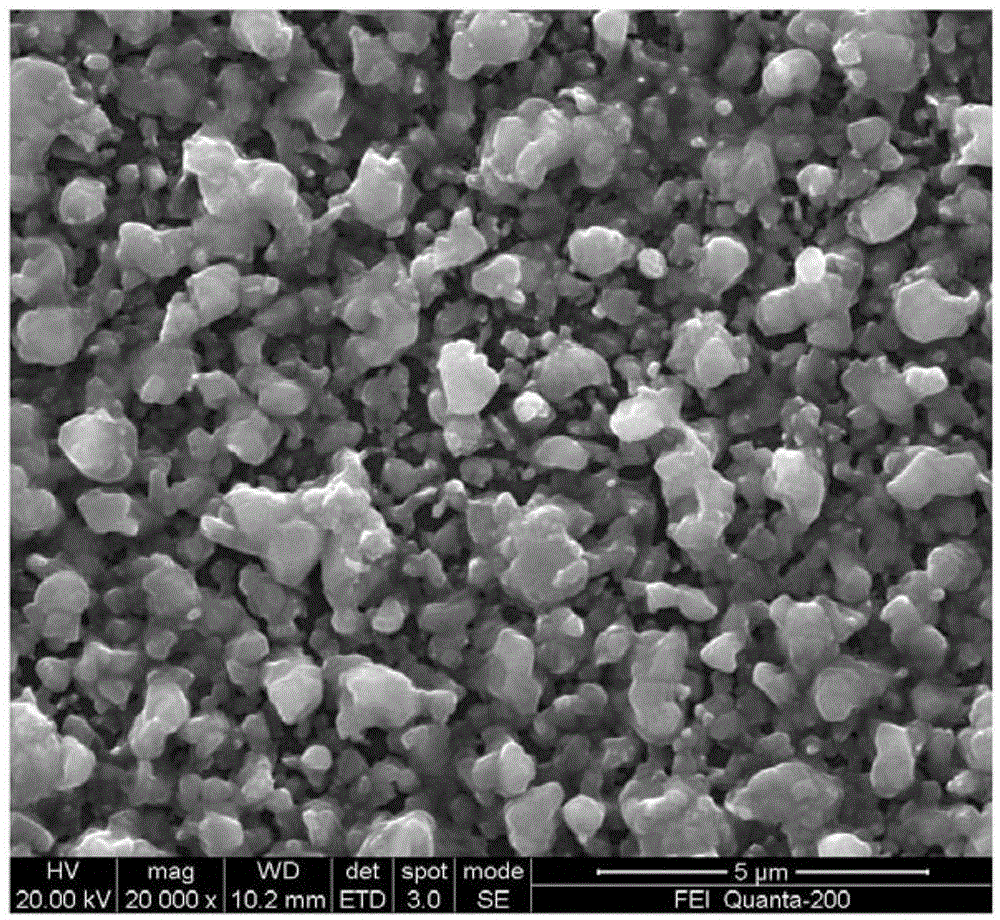

[0039] S was plated on Mo glass substrate with a thickness of 900nm by laser pulse deposition process. The solute composition of the reaction solution is 0.05mol / L CuSO 4 , 0.1mol / L SeO 2 , 1.5mol / L K 2 S 2 o 3 , 1mol / L K 2 SO 3 , adjust the pH to 4 with dilute hydrochloric acid or sodium hydroxide; adopt the following photochemical deposition parameters: the incident light is a monochromatic light source of 300nm (the light intensity is 300mW / cm 2 ), the solution temperature was 50°C, and the deposition time was 100 minutes. Deposit a 3-4 μm thick copper indium gallium selenide thin film Cu on the surface of the substrate a In b Ga c Se d , and finally the film was placed in Se-containing nitrogen and heat-treated at 450° C. for 60 minutes. The surface of the prepared film is smooth and dense, without cracks and holes, and the grain size is also significantly improved.

Embodiment 3

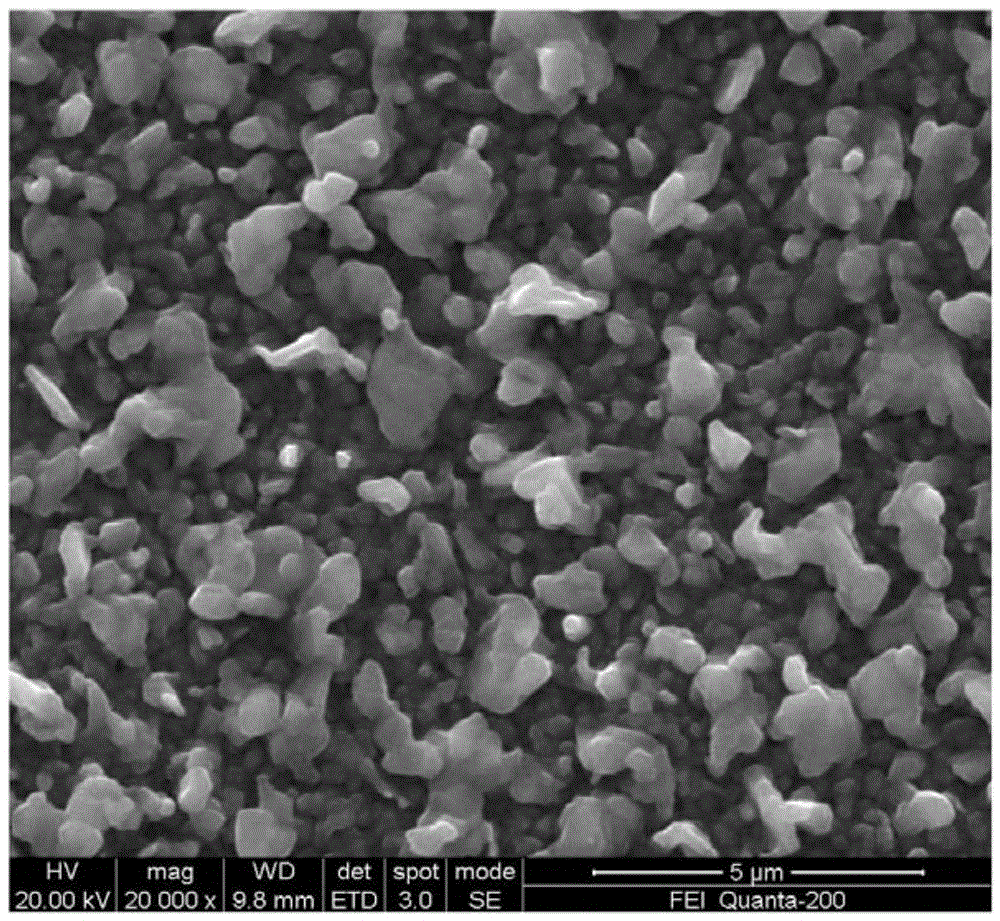

[0041] Se was plated on Mo glass substrate with a thickness of 800nm by magnetron sputtering process. First, the solute composition is 0.02mol / L CuCl 2 , 0.01mol / L InCl 3 , 0.01mol / L SeO 2 , 0.75mol / L Li 2 S 2 o 3 , adjust the pH to 6 with dilute hydrochloric acid or sodium hydroxide; adopt the following photochemical deposition parameters: the incident light is a monochromatic light source of 700nm (the light intensity is 300mW / cm 2 ), the solution temperature was 80°C, and the deposition time was 20 minutes. Deposit a 0.5 μm thick CuInGaSe thin film Cu on the substrate surface a In b Ga c Se d , and finally the film was placed in Se-containing nitrogen and heat-treated at a temperature of 500° C. for 0.6 hours. The surface of the prepared film is smooth and dense, without cracks and holes, and the grain size is also significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com