Multifunctional integrated Fe-Al-Ta eutectic composite and preparation method thereof

A technology of fe-al-ta and composite materials, applied in the field of process technology, can solve problems such as poor stability and low utilization rate, and achieve the effects of prolonging service life, improving utilization rate, and expanding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

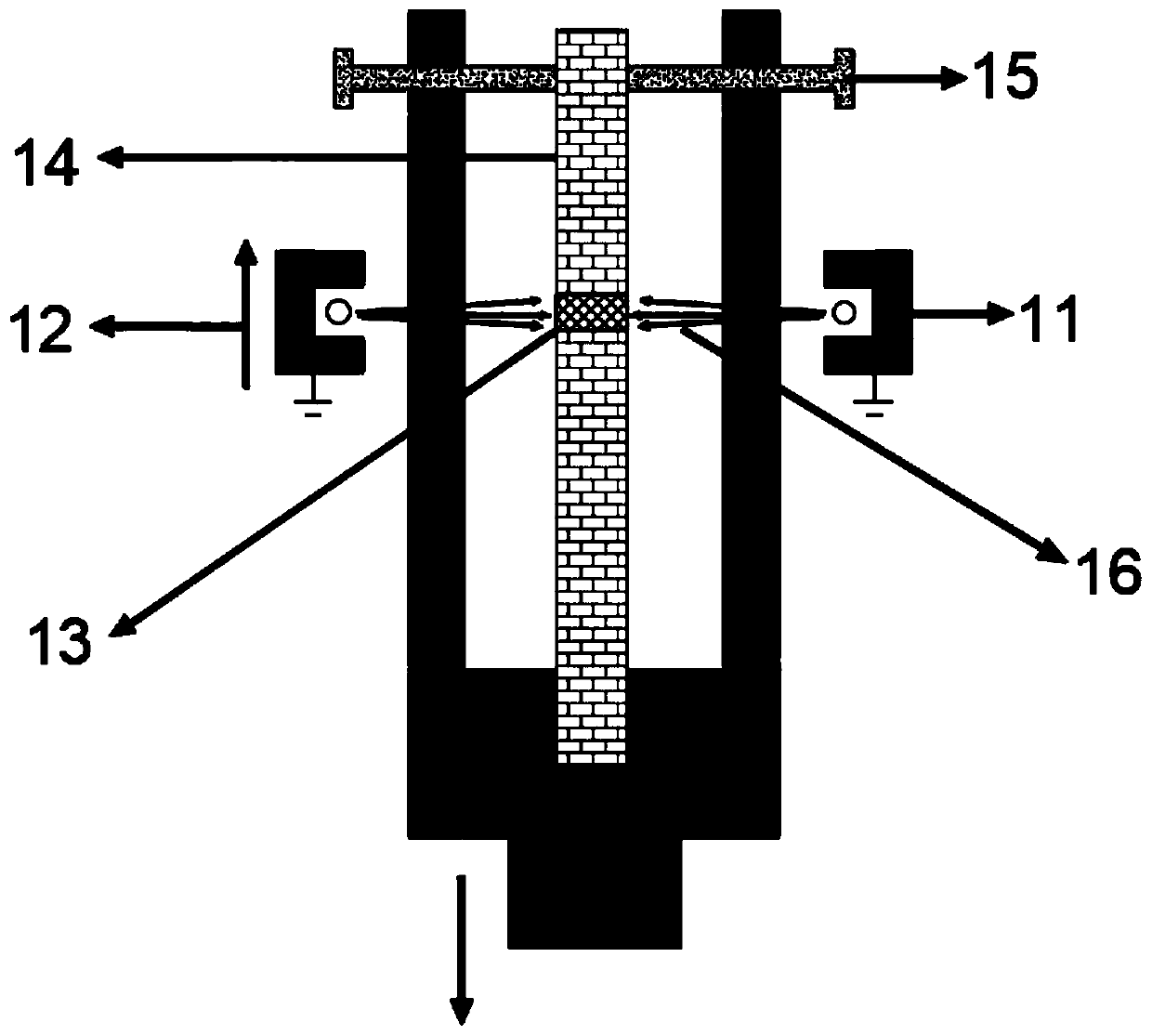

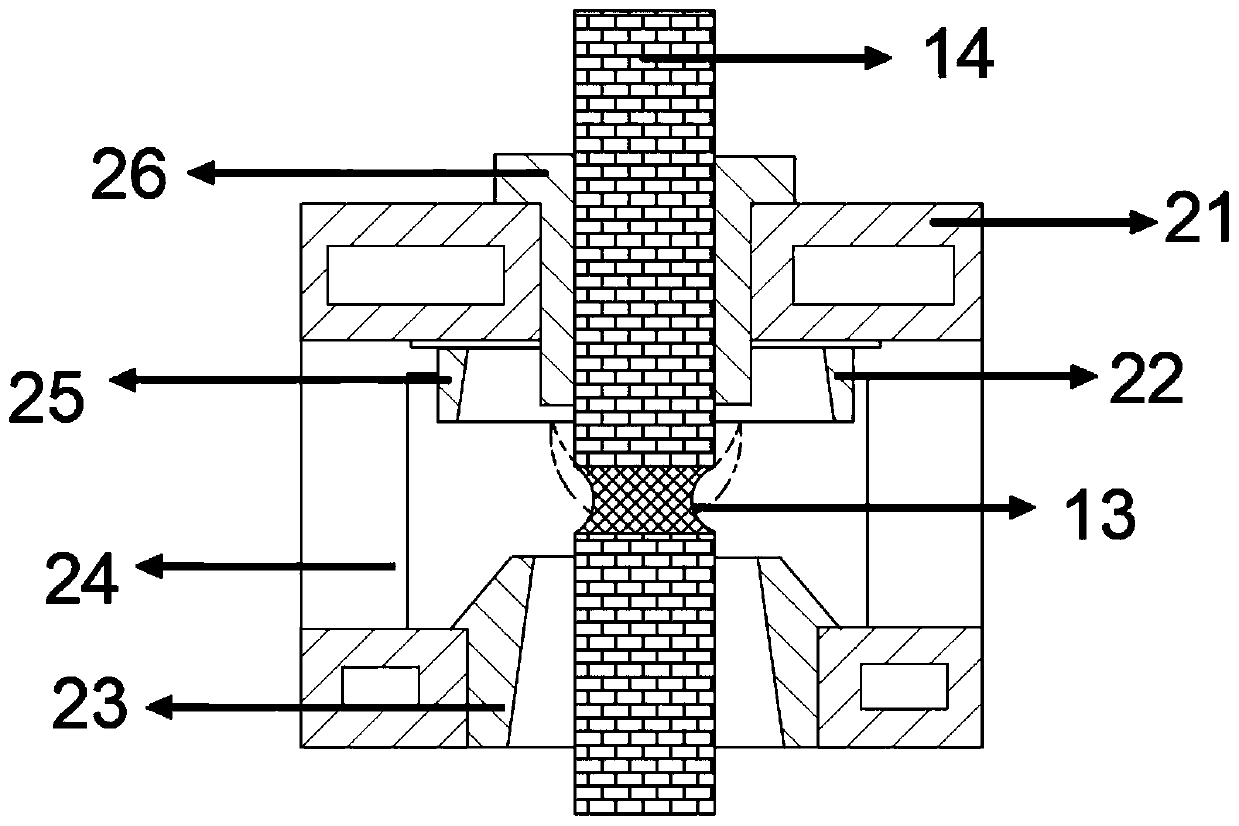

[0068] 1) Install the wire-cut material vertically in the clamping structure with clamps, in a vacuum of 1.4-1.6×10 -4 mbar, conduction ratio of 30%, accelerating voltage of 8.7KV, emission current of 11mA electron beam suspension area melting equipment (1600 ℃) to conduct directional solidification experiments to melt the material area.

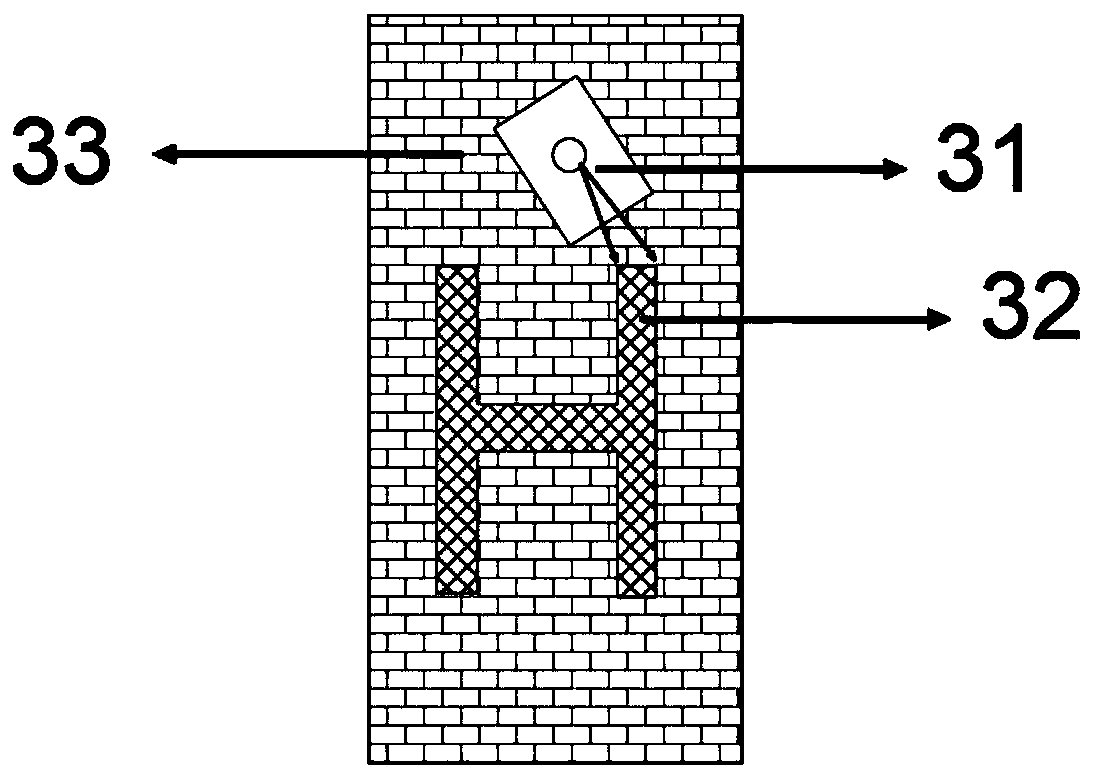

[0069] 2) When the material is in service, it is required that its high temperature creep resistance, fracture resistance and room temperature plasticity are good, then by controlling the drawing rate, it is directional solidified at a low solidification rate from bottom to top, that is, the solidification rate is 0~ 6μm / s. In this way, a bulk material with lamellar eutectic microstructure can be obtained, which has high high temperature creep resistance. like Figure 5 (a).

[0070] 3) When the surface of the material part does not need the properties of metal, such as Figure 5 (a) As shown in the square area on the front (the shape of...

Embodiment 2

[0072] 1) Install the wire-cut material vertically in the clamping structure with clamps, in a vacuum of 1.4-1.6×10 -4 mbar, conduction ratio of 30%, accelerating voltage of 8.7KV, emission current of 11mA electron beam suspension area melting equipment (1600 ℃) to conduct directional solidification experiments to melt the material area.

[0073] 2) When the material is in service, part of it is required to have good high temperature creep resistance, fracture resistance and room temperature plasticity, and the other part requires good plasticity, toughness and fatigue resistance, etc., by controlling the pulling rate, bottom-up Perform directional solidification. The parts that require high temperature creep resistance, fracture resistance and room temperature plasticity are solidified at a low rate, and the parts that require good plasticity, toughness and fatigue resistance are solidified at a higher rate. For example, the lower half of the material is solidified at a low ...

Embodiment 3

[0076] 1) Install the wire-cut material vertically in the clamping structure with clamps, in a vacuum of 1.4-1.6×10 -4 mbar, conduction ratio of 30%, accelerating voltage of 8.7KV, emission current of 11mA electron beam suspension area melting equipment (1600 ℃) to conduct directional solidification experiments to melt the material area.

[0077] 2) When the material is in service, if it is required to have three different properties and have more diversified properties, the sample area is melted by the movement of the electron gun, and directional solidification is carried out from bottom to top. Solidify at a higher rate (200-600μm / s) in parts that require plasticity, toughness and fatigue resistance; solidify at a low rate (≤6μm / s) in parts that require high temperature creep resistance, fracture resistance and room temperature plasticity ; High-speed (600-900μm / s) solidification is required for parts with high wear resistance and high strength. For example, the material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com