Aquaculture wastewater treatment process

A technology for aquaculture and wastewater treatment, which is applied in animal husbandry wastewater treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

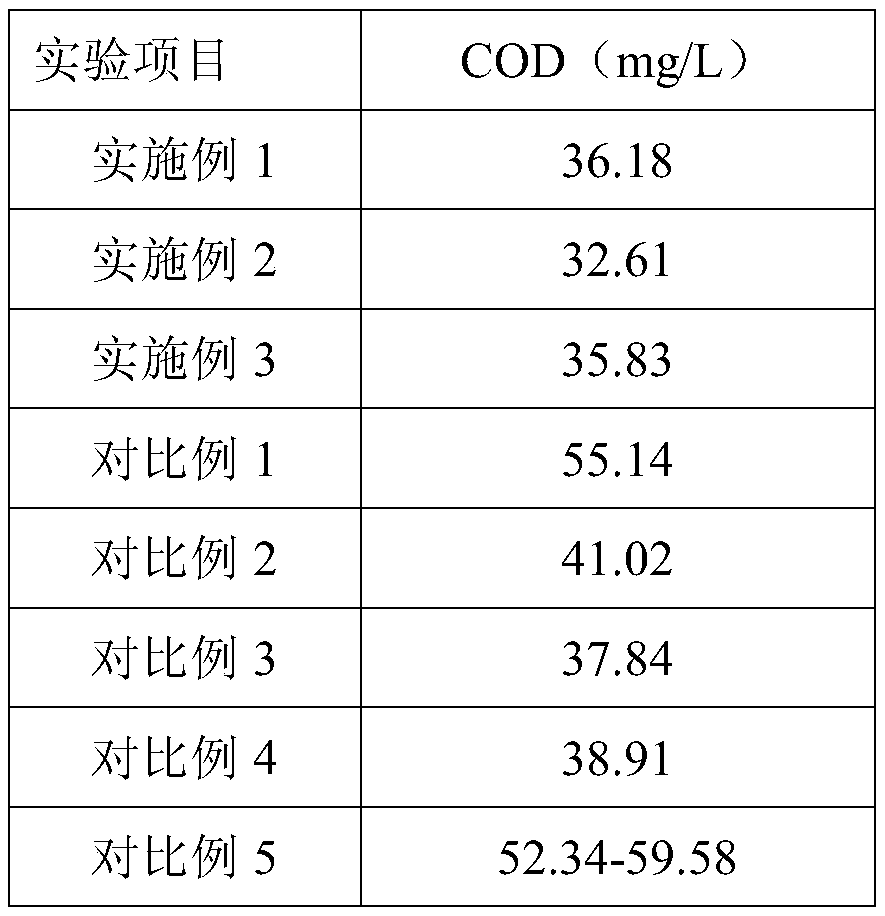

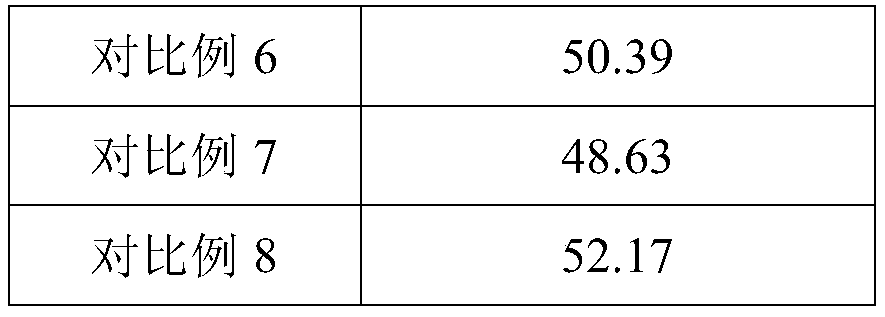

Examples

preparation example Construction

[0036] The preparation method of described aquaculture wastewater treatment agent, comprises the following steps:

[0037] S1: Weigh raw materials by weight;

[0038] S2: Take ammonium persulfate, bentonite, potassium humate, fatty alcohol polyoxyethylene ether ammonium sulfate, add 10-12 times the water and let it stand for 13-15 hours, take it out and put it in a cool place and spread it out to dry until the moisture content is 4%-6 %, then pulverized to obtain material A;

[0039] S3: Add potassium silicate, diisopropylcarbodiimide, and bacterial extracellular enzyme to the material A prepared in step S2, mix and stir at 48-52°C for 26-30min, and then pulverize to obtain aquaculture wastewater treatment agent;

[0040] (4) filtering to remove the solid content in the aquaculture wastewater after step (3) treatment;

[0041] (5) Add deodorizing and decolorizing agent to the aquaculture wastewater after step (4) removes solid content, and stir for 4-6h, wherein the addition ...

Embodiment 1

[0045] A kind of aquaculture wastewater treatment process, comprises the following steps:

[0046] (1) Removing solid waste in aquaculture wastewater by sedimentation;

[0047] (2) aerating the aquaculture wastewater treated in step (1) for 3.2 hours;

[0048] (3) Add the aquaculture wastewater treatment agent to the aquaculture wastewater treated in step (2), the temperature of the aquaculture wastewater before adding the aquaculture wastewater treatment agent is 32°C, and the addition amount of the aquaculture wastewater treatment agent is 13.1kg / m 3 , while aerating the aquaculture wastewater for 25 hours;

[0049] The aquaculture wastewater treatment agent, in parts by weight, comprises the following components: 24 parts of potassium silicate, 8 parts of diisopropylcarbodiimide, 4 parts of ammonium persulfate, 0.6 part of bacterial extracellular enzyme, bentonite 6 parts, potassium humate 2 parts, fatty alcohol polyoxyethylene ether ammonium sulfate 0.7 part.

[0050] ...

Embodiment 2

[0059] A kind of aquaculture wastewater treatment process, comprises the following steps:

[0060] (1) Removing solid waste in aquaculture wastewater by sedimentation;

[0061] (2) aerating the aquaculture wastewater treated in step (1) for 4.6 hours;

[0062] (3) Add the aquaculture wastewater treatment agent to the aquaculture wastewater treated in step (2), the temperature of the aquaculture wastewater before adding the aquaculture wastewater treatment agent is 35°C, and the addition amount of the aquaculture wastewater treatment agent is 17.5kg / m 3 , while aerating the aquaculture wastewater for 23 hours;

[0063] The aquaculture wastewater treatment agent comprises the following components: 32 parts of potassium silicate, 10 parts of diisopropylcarbodiimide, 5 parts of ammonium persulfate, 0.6 part of bacterial extracellular enzyme, 9 parts of bentonite, humic acid Potassium 2.4 parts, fatty alcohol polyoxyethylene ether ammonium sulfate 0.5 parts.

[0064] The prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com