Super-hydrophobic monodisperse polymer microspheres and preparation method thereof

A microsphere and superphobic technology, which is applied in the field of superhydrophobic monodisperse polymer microspheres and their preparation, can solve the problems of inapplicability to large-scale industrial production, low monomer input, and low yield of microspheres. The effect of safe and reliable conditions, environmental friendliness and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

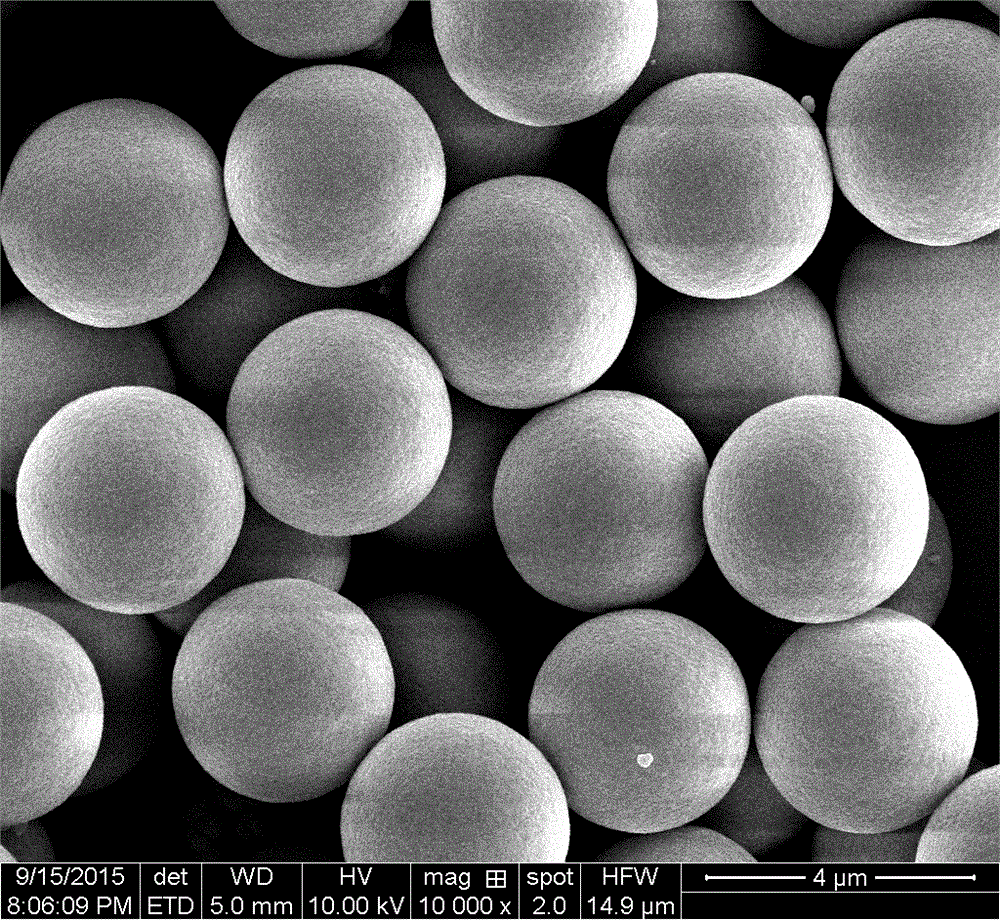

[0033] Add 2.42 ml of divinylbenzene monomer, 5.08 ml of dodecyl methacrylate monomer, 34.7 μl of N,N-dimethylaniline, and 66.6 mg of benzoyl peroxide into 30 ml of acetic acid. , added to the polytetrafluoroethylene lining of the stainless steel reaction kettle, passed through nitrogen for 15 min, and sealed after removing oxygen. Then place it in an oil bath, and the temperature of the oil bath is set to 25°C. The reaction time is 48 hours. After washing with ethanol, centrifugal precipitation, and drying, poly(dodecyl methacrylate-divinylbenzene) microspheres were obtained, with a particle size of 3.49 µm, a polydispersity coefficient of 1.012, and a yield of 29.6% ( figure 1 ). 60 mg of microspheres were dispersed into 1 ml of ethanol to form a microsphere dispersion, which was added dropwise to the glass surface and dried to obtain a substrate with a superhydrophobic surface.

Embodiment 2

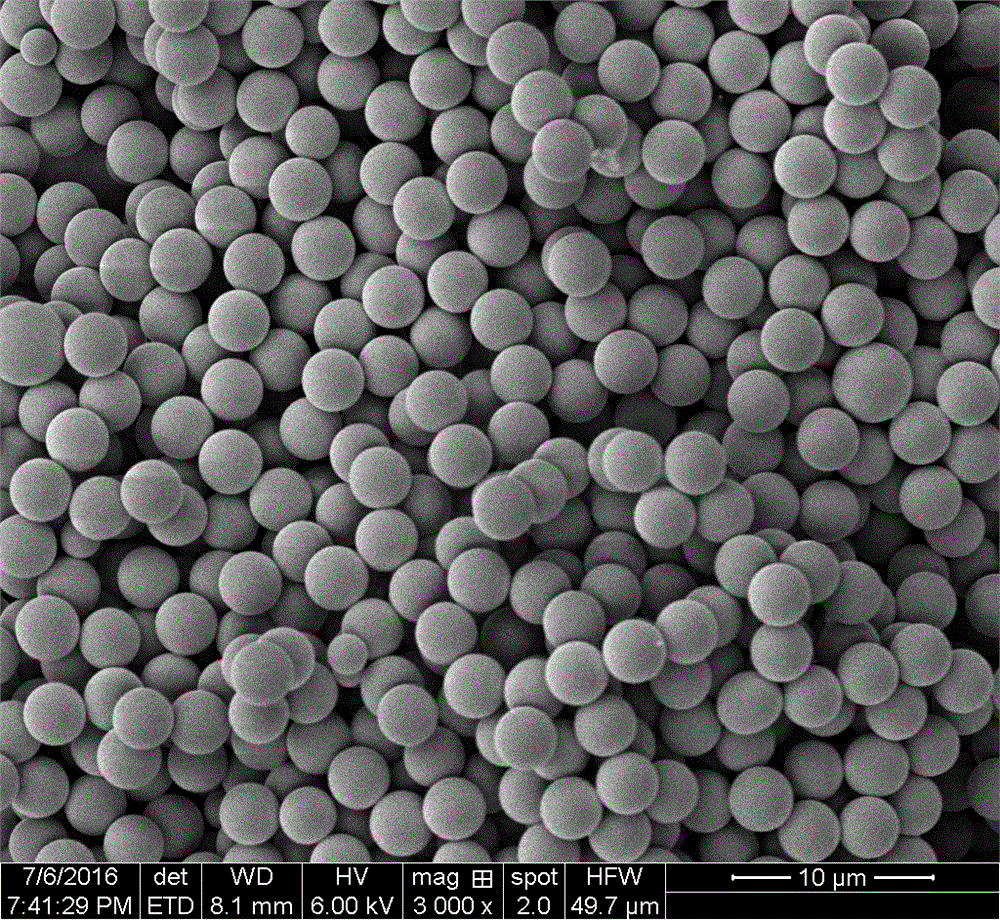

[0035] Add 1.73 ml of divinylbenzene monomer, 3.57 ml of dodecyl methacrylate monomer, and 375.4 mg of azobisisobutyronitrile into 30 ml of acetonitrile. In the inner lining, nitrogen gas was passed through for 15 minutes, and after oxygen was removed, it was sealed. Then place it in an oil bath, and the temperature of the oil bath is set to 85°C. Reaction time 4 hours. Stop heating, wash with ethanol, centrifuge, and dry to obtain poly(dodecyl methacrylate-divinylbenzene) microspheres with a particle size of 3.157 µm, a polydispersity coefficient of 1.018, and a yield of 93.6% ( figure 2 ). 60 mg of microspheres were dispersed into 1 ml of ethanol to form a microsphere dispersion, which was added dropwise to the glass surface and dried to obtain a substrate with a superhydrophobic surface.

Embodiment 3

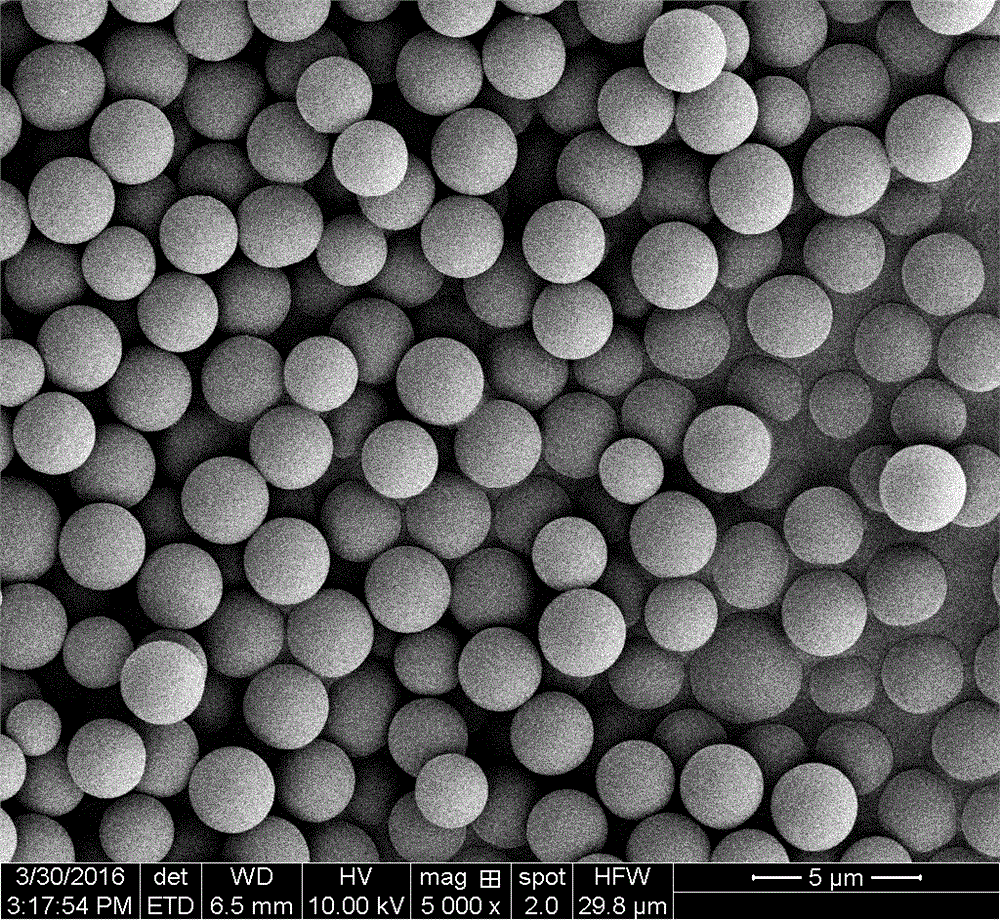

[0037] Add 3.44 ml of divinylbenzene monomer, 1.78 ml of dodecyl methacrylate monomer, and 376.4 mg of azobisisobutyronitrile into 30 ml of acetonitrile. In the inner lining, nitrogen gas was passed through for 15 minutes, and after oxygen was removed, it was sealed. Then place it in an oil bath, and the temperature of the oil bath is set to 85°C. Reaction time 4 hours. Stop heating, wash with ethanol, centrifuge, and dry to obtain poly(dodecyl methacrylate-divinylbenzene) microspheres, the particle size is 2.422 μm, the polydispersity coefficient is 1.025, and the yield is 94.2% ( image 3 ). 100 mg of microspheres were dispersed into 1 ml of ethanol to form a microsphere dispersion, which was added dropwise to the glass surface and dried to obtain a substrate with a superhydrophobic surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com