Additive for alcohol base liquid fuel

A liquid fuel and additive technology, applied in the direction of fuel additives, liquid carbon-containing fuels, fuels, etc., can solve problems such as corrosion of metal parts, lack of regulations for supporting equipment, and failure to use normally, so as to increase lubricity and viscosity, change The effect of burning flame color and increasing calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 5kg of isooctyl methacrylate, 32kg of methyl palm oleate, 12kg of dodecyl methacrylate, 15kg of dioctyl phthalate, 1kg of isopropyl benzoate and dibutyl dithio Add 6kg of zinc carbamate into the mixing tank, heat up to 80°C, and react with 20KHz ultrasonic stirring for 2 hours. Cool to room temperature, then add 6kg of 2,4-dimethyl-6-tert-butylphenol, 3kg of N,N'-disalicylidene-1,2-propylenediamine, 5kg of diethylene glycol monomethyl ether, Diethylaminoethyl methacrylate 4kg, 2-n-octyl-4-isothiazolin-3-ketone 7kg, N-phenyl-N-sec-butylphenylenediamine 4kg, continue to stir for 20 minutes to reconcile evenly, prepare 100kg civil alcohol-based liquid fuel additive.

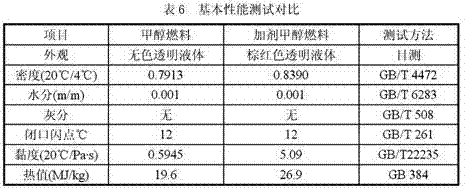

[0031] Take 8kg of the above-prepared additive and add it into 92kg of methanol to prepare 100kg of alcohol-based liquid fuel. The metal corrosion inhibition performance and other basic properties of the fuel are tested.

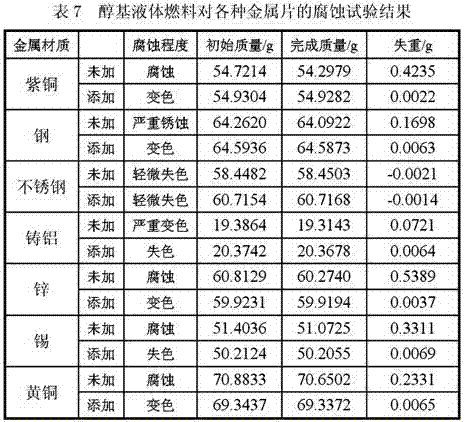

[0032] Metal corrosion inhibition performance test refers to SAEJ 1747 "Recomme...

Embodiment 2

[0038] Take by weighing isooctyl polymethacrylate 7kg, methyl palm oleate 28kg, lauryl methacrylate 14kg, dioctyl phthalate 11kg and zinc dibutyl dithiocarbamate 8kg, add to In the mixing tank, the temperature was raised to 80° C., and the mixture was stirred and reacted with 20 KHz ultrasonic waves for 2 hours. Cool to room temperature, then add 10kg of 2,4-dimethyl-6-tert-butylphenol, 2kg of N,N'-disalicylidene-1,2-propylenediamine, 3kg of diethylene glycol monomethyl ether, Diethylaminoethyl methacrylate 6kg, 2-n-octyl-4-isothiazolin-3-ketone 5kg, N-phenyl-N-sec-butylphenylenediamine 11kg, continue to stir for 20 minutes to reconcile evenly, prepare 100kg civil alcohol-based liquid fuel additive.

[0039] Test the performance of the additive according to the method of Example 1, and the results are shown in Table 3 and Table 4.

[0040]

[0041]

Embodiment 3

[0043]Weigh polyisooctyl methacrylate 7kg, methyl palm oleate 22kg, dodecyl methacrylate 8kg, dioctyl phthalate 15kg, isopropyl benzoate 3kg and dibutyl dithio Add 4kg of zinc carbamate into the mixing tank, heat up to 80°C, and react with 20KHz ultrasonic stirring for 2 hours. Cool to room temperature, then add 11kg of 2,4-dimethyl-6-tert-butylphenol, 1kg of N,N'-disalicylidene-1,2-propylenediamine, 6kg of diethylene glycol monomethyl ether, Diethylaminoethyl methacrylate 4kg, 2-n-octyl-4-isothiazolin-3-ketone 7kg, N-phenyl-N-sec-butylphenylenediamine 12kg, continue to stir for 20 minutes to reconcile evenly, prepare 100kg civil alcohol-based liquid fuel additive.

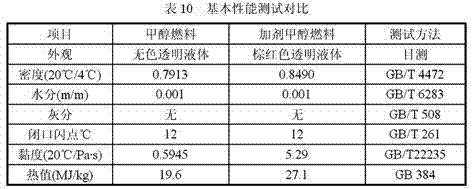

[0044] Test the performance of the additive according to the method of Example 1, and the results are shown in Table 5 and Table 6.

[0045]

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com