A naturally degradable polymer gel water-based fire extinguishing agent

A technology of polymer gel and fire extinguishing agent, applied in fire protection equipment and other directions, can solve problems such as poor degradation performance and secondary pollution of the environment, and achieve the effect of improving degradable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

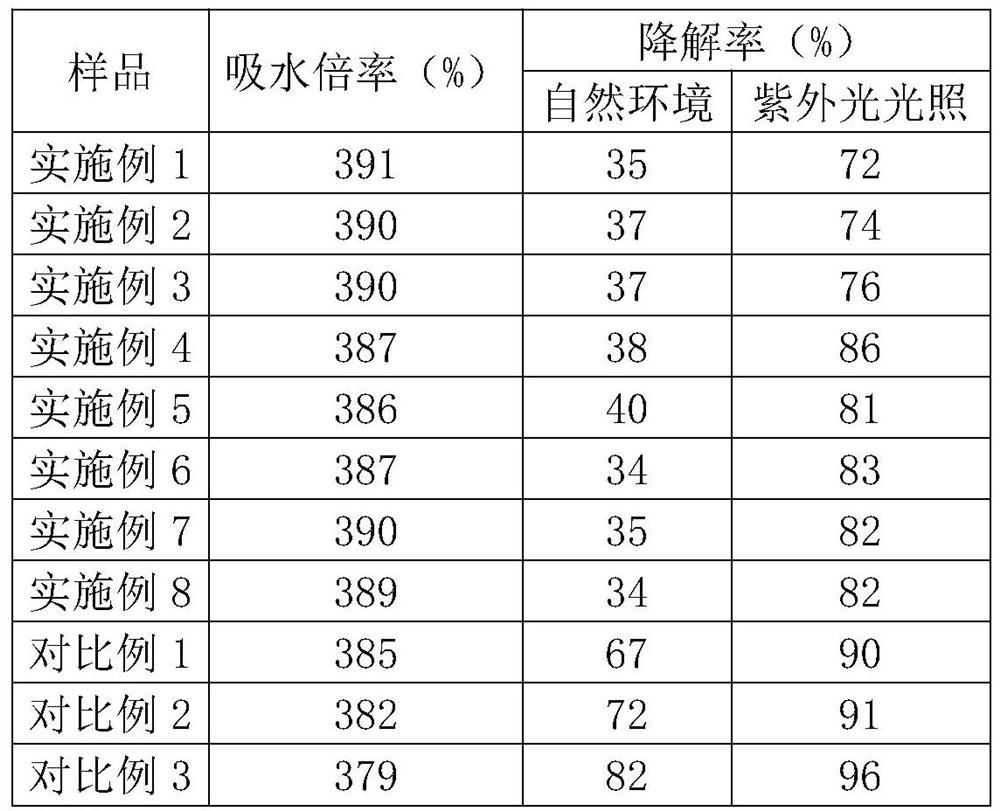

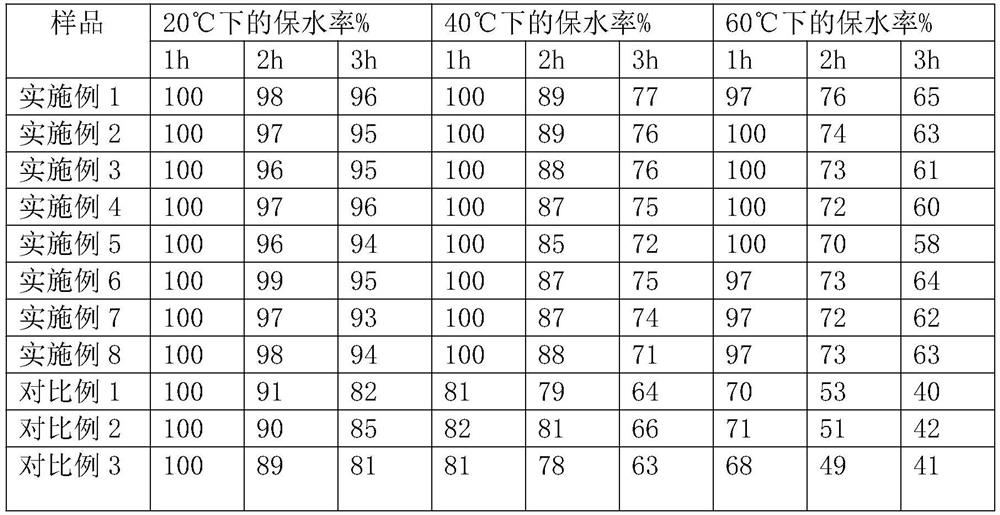

Examples

Embodiment 1

[0036] A naturally degradable polymer gel water-based fire extinguishing agent, comprising 50 parts of lignocellulose-modified SA resin and 56 parts of polyacrylamide;

[0037] The modified SA resin is a benzoin-SA compound, and its preparation method is:

[0038] 1) Put 45 parts of SA, 3 parts of diluent and 8 parts of propylene glycol solution into the mixer, and stir at 120°C until the acid value of the mixed solution is 18;

[0039] 2) Add 3 parts of benzoin to the above mixed solution, and continue stirring for 1 hour;

[0040] 3) Put the mixed solution in step 2) into a screw extruder for extrusion molding, and then cool to room temperature to obtain a benzoin-SA compound.

[0041] The preparation method of lignocellulose modified SA resin is:

[0042] 1) Dissolution of lignocellulose: according to the weight and number ratio of benzoin-SA compound and lignocellulose is 1:0.15, add weight parts of lignocellulose until the mass fraction is 5% sodium hydroxide solution a...

Embodiment 2

[0047] A kind of naturally degradable polymer gel water system fire extinguishing agent, including 40 parts of lignocellulose modified SA resin, 46 parts of polyacrylamide;

[0048] The modified SA resin is a benzoin-SA compound, and its preparation method is the same as in Example 1;

[0049] The difference between the preparation method of lignocellulose-modified SA resin and Example 1 is that the ratio of benzoin-SA compound to lignocellulose by weight is 1:0.15.

Embodiment 3

[0051] A kind of naturally degradable polymer gel water system fire extinguishing agent, including 60 parts of lignocellulose modified SA resin, 72 parts of polyacrylamide;

[0052] The modified SA resin is a benzoin-SA compound, and its preparation method is the same as in Example 1;

[0053] The difference between the preparation method of lignocellulose-modified SA resin and Example 1 is that the ratio of benzoin-SA compound to lignocellulose by weight is 1:0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com