Micro-extraction monolithic column of ionic liquid polymer capillary tube and preparation method thereof

An ionic liquid and capillary technology, which is applied in the fields of polymer materials and analytical chemistry, can solve the problems such as the monolithic ionic liquid column, which affects the stability and extraction performance of the column, and achieves easy regulation of reaction conditions, uniform internal structure and pore size distribution. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix 0.05 g lauryl methacrylate and 0.05 g 1-allyl-3-octylimidazolium hexafluorophosphate binary monomer, 0.15 g ethylene glycol dimethacrylate crosslinker, 0.003 g Azobisisobutyronitrile initiator and mixed porogen (n-propanol 0.3 g, butanediol 0.3 g) were mixed at room temperature and ultrasonically oscillated for 20 min to obtain a reactant solution, which was injected into a vinyl-treated capillary. Both ends were sealed, immersed in a water bath at 60°C to initiate the polymerization reaction for 15 h; after the reaction was completed, the column was washed with methanol to remove unreacted monomers, cross-linking agents and porogens in the capillary, and 1-ene was obtained after drying Propyl-3-octylimidazole ionic liquid-dodecyl methacrylate-ethylene glycol dimethacrylate polymer monolithic column for capillary microextraction.

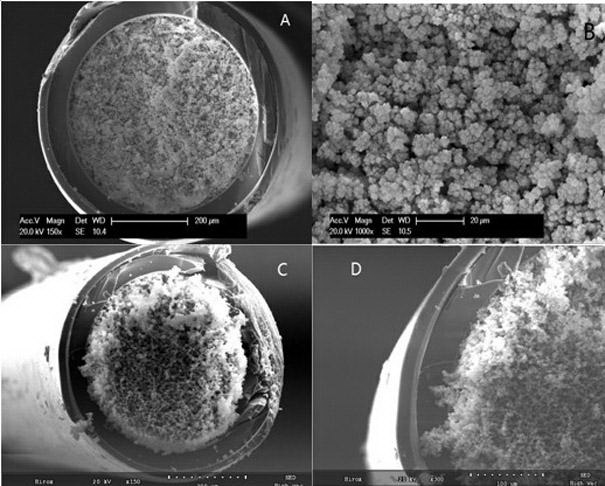

[0019] figure 1 A and B show the global and local images of the SEM images of the monolithic column. The figure shows that after dopi...

Embodiment 2

[0024] 0.05 g dodecyl methacrylate monomer, 0.15 g ethylene glycol dimethacrylate crosslinking agent, 0.003 g azobisisobutyronitrile initiator and mixed porogen (n-propanol 0.3 g, Butanediol 0.3 g), mixed at room temperature and ultrasonically oscillated for 20 min to obtain a reactant solution, injected into a vinyl-treated capillary, sealed at both ends, immersed in a 60°C water bath to initiate polymerization for 15 h; after the reaction was completed, Rinse the column with methanol to remove unreacted monomers, cross-linking agents and porogens in the capillary, and dry to obtain dodecyl methacrylate-ethylene glycol dimethacrylate polymer capillary solid-phase microextraction monolithic column.

[0025] figure 1 C and D show the global and local images of the SEM images of the monolithic microextraction column. It can be seen from the figure that, compared with the ionic liquid polymer microextraction monolithic column in Example 1, the ionic liquid-free polymer microex...

Embodiment 3

[0027]0.05 g lauryl methacrylate and 0.05 g 1-allyl-3-hexylimidazolium hexafluorophosphate binary monomer, 0.2 g ethylene glycol dimethacrylate crosslinker, 0.003 g AZBN initiator and mixed porogen (n-propanol 0.3 g, butanediol 0.3 g) were mixed at room temperature and ultrasonically oscillated for 20 min to obtain a reactant solution, which was injected into a vinyl-treated capillary tube. The end was sealed, and immersed in a 70°C water bath to initiate a polymerization reaction for 16 h; after the reaction was completed, the column was washed with methanol to remove unreacted monomers, cross-linking agents and porogens in the capillary, and dried to obtain 1-allyl - 3-hexylimidazole ionic liquid - dodecyl methacrylate - ethylene glycol dimethacrylate polymer monolithic column for capillary microextraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com