Weak solvent ink absorption flame retardant coating and preparation method thereof

A technology of absorbing coating and flame-retardant coating, which is applied in the field of materials, can solve problems such as unsafe, toxic smoke, and slow volatilization of weak solvents, and achieve the effects of good flame retardancy, enhanced ink absorption ability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

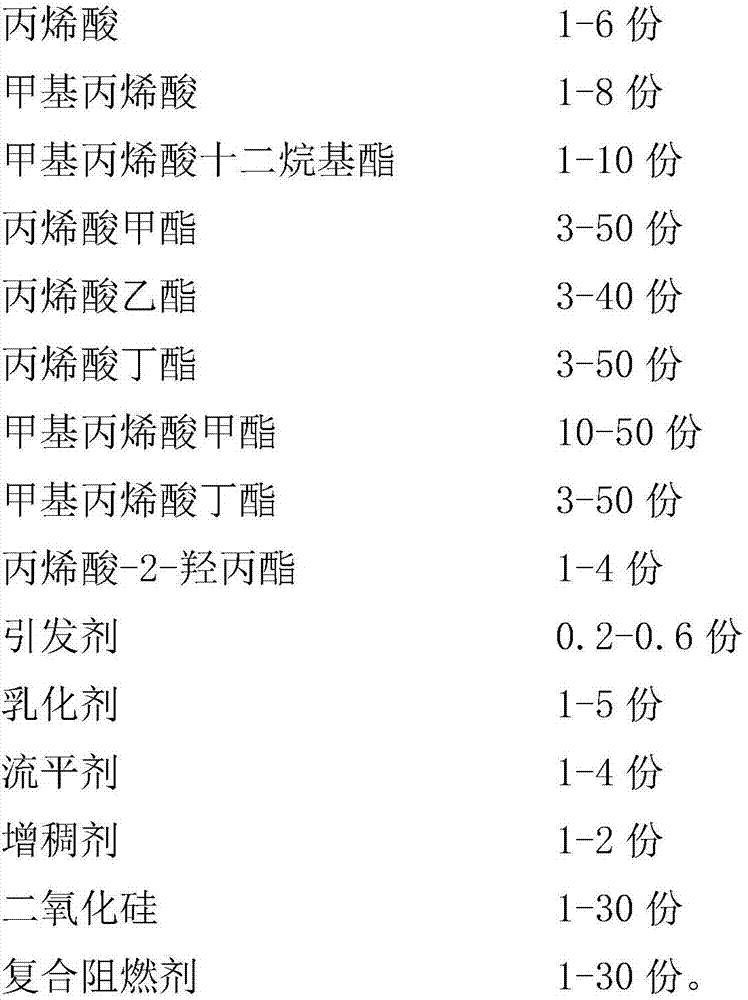

[0032] (1) According to the formula, weigh the following components:

[0033]

[0034] The addition ratio of the above-mentioned composite combustion-supporting agent is: melamine modified ammonium polyphosphate, decabromodiphenylethane, and antimony trioxide in a mass ratio of 2:3:1.

[0035] (2) Add 2 / 3 weight of emulsifier, acrylic acid, methacrylic acid, lauryl methacrylate, methyl acrylate, ethyl acrylate, butyl acrylate, methyl methacrylate, butyl methacrylate Ester, 2-hydroxypropyl acrylate and 1 / 3 of the initiator by weight are added to the water at a water-oil ratio of 2-0.6:1, and stirred at high speed for 30 minutes;

[0036] (3) Stir the remaining 1 / 3 weight of the emulsifier and the remaining 2 / 3 weight of the initiator to form a mixed emulsion;

[0037] (4). The reaction system of step (2) is heated to 82°C, the mixed emulsion in step (3) is added dropwise, and the dripping is completed in 3 hours; the temperature is raised to 86°C, and the temperature is kept for 1 hour...

Embodiment 2

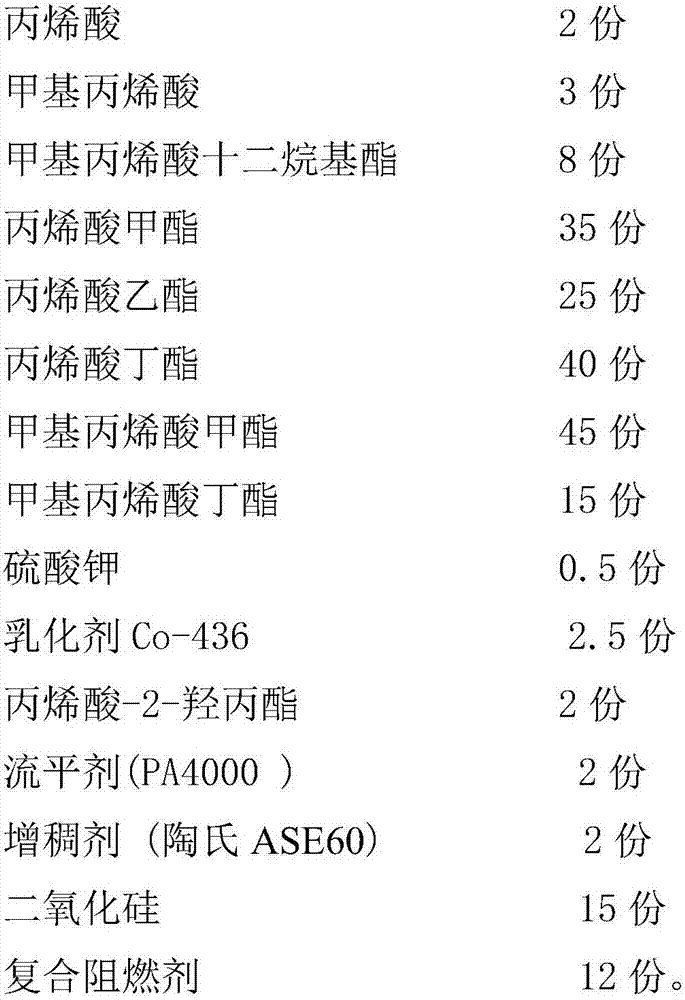

[0041] (1) According to the formula, weigh the following components:

[0042]

[0043] The addition ratio of the above-mentioned composite combustion-supporting agent is: melamine modified ammonium polyphosphate, decabromodiphenylethane, and antimony trioxide in a mass ratio of 2:3:1.

[0044] (2) Add 2 / 3 weight of emulsifier, acrylic acid, methacrylic acid, lauryl methacrylate, methyl acrylate, ethyl acrylate, butyl acrylate, methyl methacrylate, butyl methacrylate Ester, 2-hydroxypropyl acrylate and 1 / 3 weight of sodium sulfate are added to water at a water-oil ratio of 2-0.6:1, and stirred at high speed for 30 minutes;

[0045] (3) Stir the remaining 1 / 3 weight of emulsifier and the remaining 2 / 3 weight of sodium sulfate to form a mixed emulsion;

[0046] (4). The reaction system of step (2) is heated to 80°C, the mixed emulsion in step (3) is added dropwise, and the addition is completed in 4 hours; the temperature is raised to 86°C, and the temperature is kept for 1 hour.

[0047]...

Embodiment 3

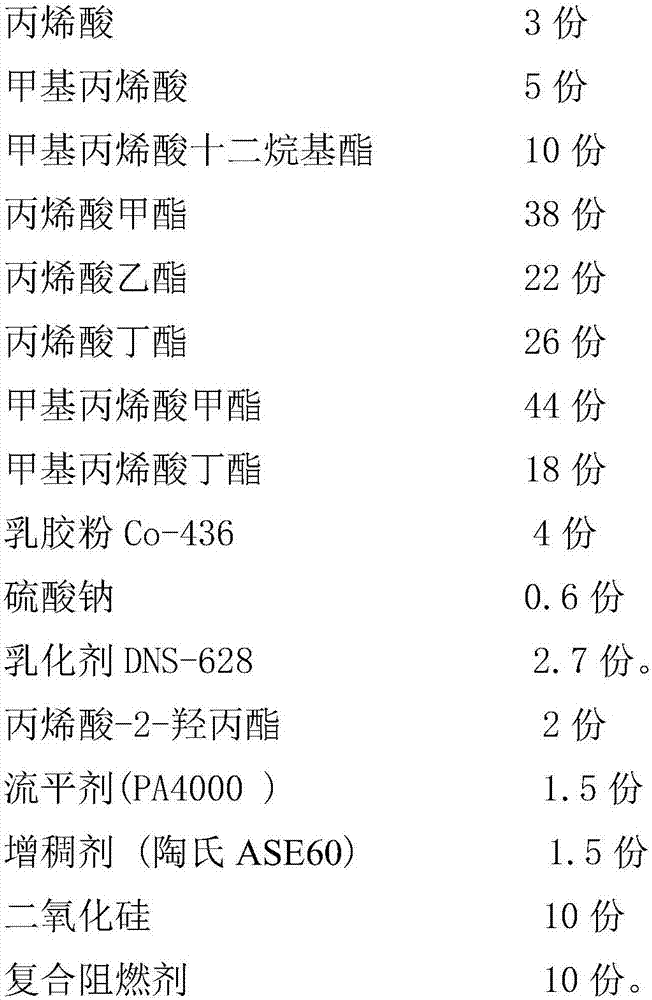

[0050] (1) According to the formula, weigh the following components:

[0051]

[0052]

[0053] The addition ratio of the above-mentioned composite combustion-supporting agent is: melamine modified ammonium polyphosphate, decabromodiphenylethane, and antimony trioxide in a mass ratio of 2:3:1.

[0054] (2) Add 2 / 3 weight of emulsifier, acrylic acid, methacrylic acid, lauryl methacrylate, methyl acrylate, ethyl acrylate, butyl acrylate, methyl methacrylate, butyl methacrylate Ester, 2-hydroxypropyl acrylate and 1 / 3 weight of sodium sulfate are added to water at a water-oil ratio of 2-0.6:1, and stirred at high speed for 30 minutes;

[0055] (3) Stir the remaining 1 / 3 weight of emulsifier and the remaining 2 / 3 weight of sodium sulfate to form a mixed emulsion;

[0056] (4) The reaction system of step (2) is heated to 80°C, the mixed emulsion in step (3) is added dropwise, and the dripping is completed in 3 hours; the temperature is raised to 86°C, and the temperature is kept for 1 hour....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com