Graphene modified steel structure water-based anti-corrosive paint and preparation method thereof

A graphene modification and anti-corrosion coating technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems affecting the anti-corrosion performance of the coating film, the solvent resistance, water resistance and stain resistance of the coating film, and the water absorption of the coating film. Large and other problems, to achieve excellent storage and anti-corrosion performance, improve poor water resistance and weather resistance, and improve the effect of easy flash rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

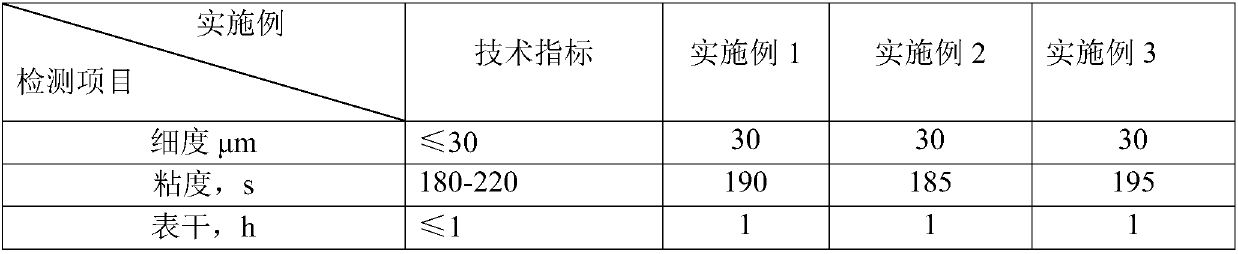

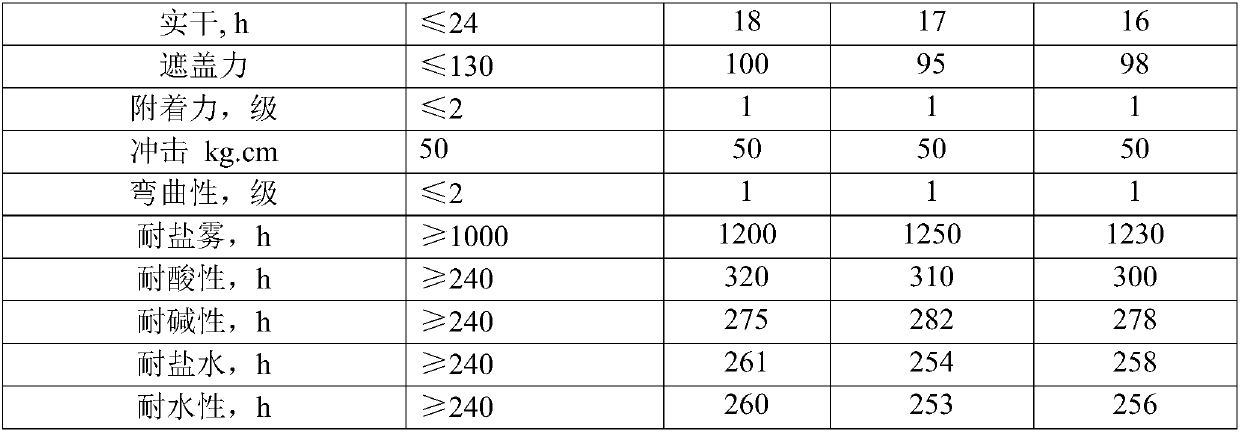

Embodiment 1

[0028] Embodiment 1 graphene modified steel structure water-based anticorrosion coating

[0029] Raw materials: graphene dispersion: XF020 monolayer graphene oxide dispersion; anionic acrylic emulsion; pigment: ferric oxychloride, self-made; filler: superfine calcium carbonate; wetting and dispersing agent: METOTAT388; defoaming agent: TCB-1 ; pH regulator: SILRES-BS168; thickener: cellulose thickener; SiO 2 Hollow microspheres; RS preservatives; film-forming aids: JS-PPh(302). The ferric oxychloride uses ferric chloride hexahydrate as raw material, grinds ferric chloride hexahydrate into a powder smaller than 30 microns, and then calcines at 260°C for 4 hours; the product obtained after calcining is cooled to room temperature and washed with acetone Remove unreacted ferric chloride; dry overnight at 80°C under the protection of nitrogen until drying to obtain ferric oxychloride.

[0030] The above raw materials can be obtained through market purchase unless otherwise specif...

Embodiment 2

[0036] Embodiment 2 graphene modified steel structure water-based anticorrosion coating

[0037] Raw material: with embodiment 1

[0038] In weight percent, the anti-corrosion coating contains 15% deionized water, 10% graphene dispersion, 38% anionic acrylic emulsion, 5% pigment, 28% filler, 0.2% wetting and dispersing agent , 0.2% defoamer, 0.3% pH regulator, 0.6% thickener, 0.3% SiO 2Hollow microspheres, 0.2% RS anticorrosion agent and 2.2% film-forming aid; the sum of the weight percentages of each component in the graphene-modified steel structure water-based anticorrosion coating is 100%.

[0039] The preparation method is the same as in Example 1.

Embodiment 3

[0040] Embodiment 3 graphene modified steel structure water-based anticorrosion coating

[0041] Raw material: with embodiment 1

[0042] In percent by weight, the anticorrosion coating comprises 10% deionized water, 7% graphene dispersion, 40% anionic acrylic emulsion, 10% pigment, 25% filler, 0.7% wetting and dispersing agent, 0.5% defoamer, 0.5% pH regulator, 0.5% thickener, 0.5% SiO 2 Hollow microspheres, 0.3% RS anticorrosion agent and 5% film-forming aid; the sum of the weight percentages of each component in the graphene modified steel structure water-based anticorrosion coating is 100%.

[0043] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com