Graphene-based sponge as well as preparation method and application thereof

A technology of alkenyl sponge and graphene, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of troublesome recycling work, insufficient hydrophobic performance, poor oil-water selectivity, etc., achieve good treatment effect, simple operation, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] According to one aspect of the present invention, the present invention relates to a kind of preparation method of graphene-based sponge, comprises the following steps:

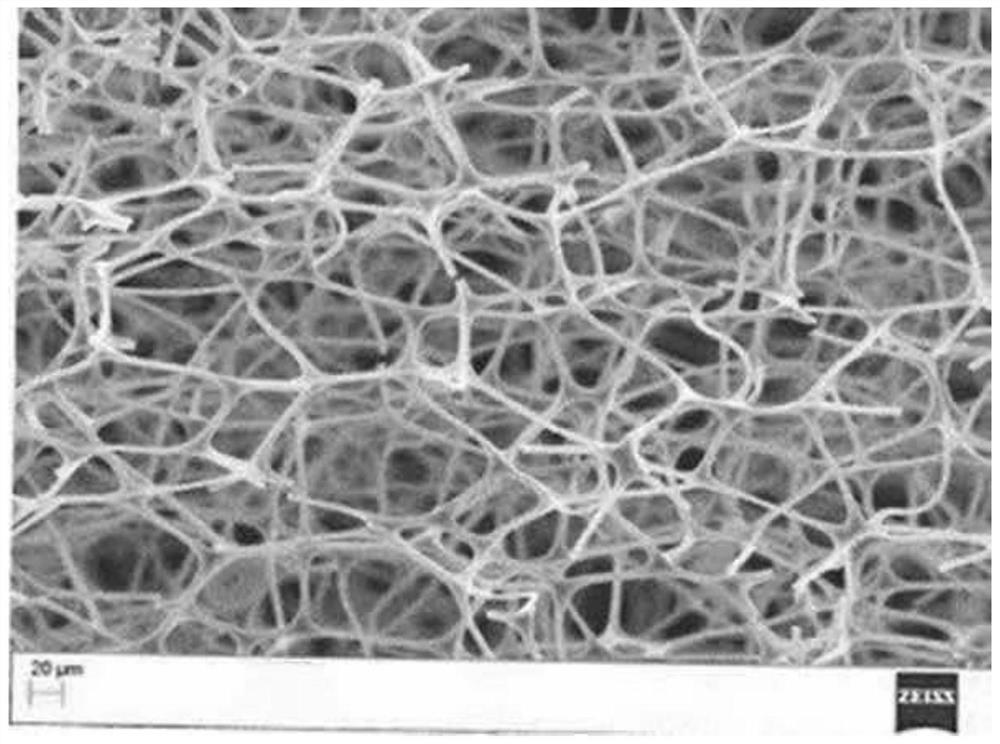

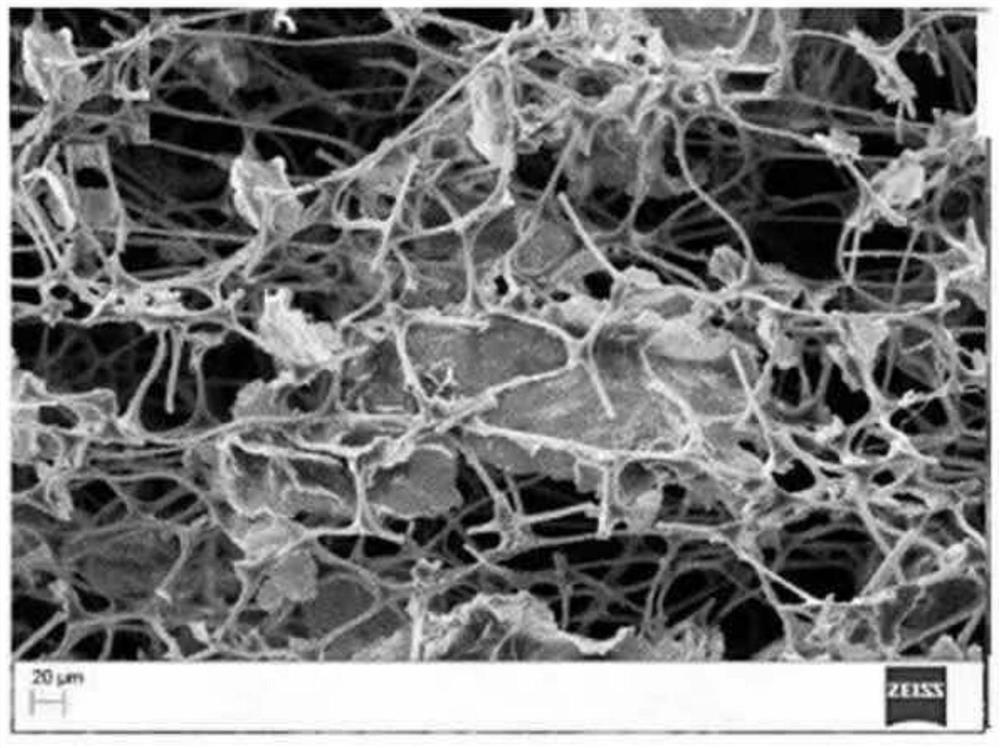

[0023] The mixture of the dispersion of graphene oxide and the polyurethane sponge is subjected to ultrasonic treatment to obtain a polyurethane sponge loaded with graphene oxide; then the polyurethane sponge loaded with graphene oxide is subjected to heat treatment;

[0024] The temperature of the heat treatment is 140-220° C., and the time of the heat treatment is 5-20 hours.

[0025] The present invention mixes the dispersion liquid of graphene oxide and polyurethane sponge and performs ultrasonic treatment, so that graphene oxide is evenly loaded on the polyurethane sponge, and then the graphene-based sponge material can be obtained through high-temperature reduction; the method does not add chemical reducing agent, Green, non-toxic, environmentally friendly, and easy to operate, the obtained graph...

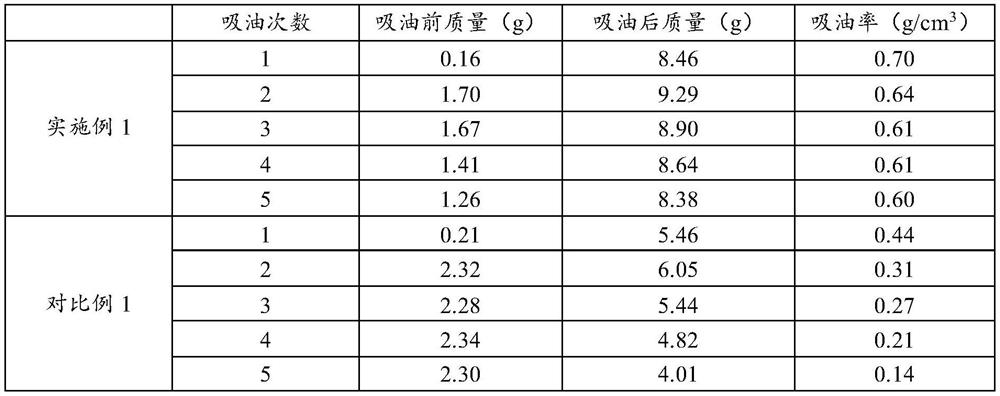

Embodiment 1

[0071] A preparation method of lipophilic and hydrophobic graphene-based sponge, comprising the following steps:

[0072] (a) ultrasonically wash the polyurethane sponge in ultrapure water and absolute ethanol for 15 minutes, then put the polyurethane sponge into a blast drying oven, and dry at 65°C for 45 minutes;

[0073] (b) take flake graphite powder, sodium nitrate, potassium permanganate respectively, at first flake graphite and sodium nitrate are added in the there-necked flask, then add the concentrated sulfuric acid that mass percentage is 98%, add magneton and stir, will The three-neck flask was placed in a crushed ice bath, and potassium permanganate was added to react for 35 minutes under the crushed ice bath condition. The flask was moved into a water bath at 45°C to continue the reaction. After 40 minutes, the temperature of the water bath was raised to 90°C. During the heating process, add Pure water, add an appropriate amount of hydrogen peroxide with a mass pe...

Embodiment 2

[0079] A preparation method of lipophilic and hydrophobic graphene-based sponge, comprising the following steps:

[0080] (a) ultrasonically wash the polyurethane sponge in ultrapure water and absolute ethanol for 10 minutes respectively, then put the polyurethane sponge into a blast drying oven, and dry at 60°C for 40 minutes;

[0081] (b) take flake graphite powder, sodium nitrate, potassium permanganate respectively, at first flake graphite and sodium nitrate are added in the there-necked flask, then add the concentrated sulfuric acid that mass percentage is 98%, add magneton and stir, will The three-necked flask was placed in a crushed ice bath, and potassium permanganate was added to react for 50 minutes under the crushed ice bath condition. The flask was moved into a 50°C water bath to continue the reaction. After 40 minutes, the temperature of the water bath was raised to 85°C. During the heating process, add Pure water, add an appropriate amount of hydrogen peroxide wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com