Bamboo fungus and tropical fruit complex active ferment and preparation method thereof

A tropical fruit, active enzyme technology, applied in the direction of bacteria used in food preparation, the function of food ingredients, yeast-containing food ingredients, etc., can solve the problems of unfavorable storage and transportation, perishability, high water content of bamboo fungus, and achieve unique The effect of taste, reduction of production cost, and pure enzyme flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

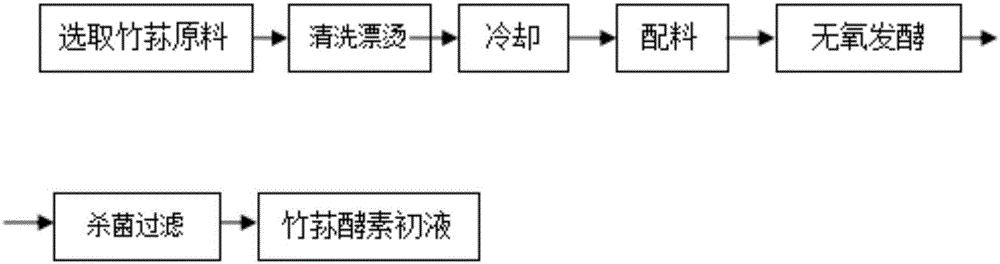

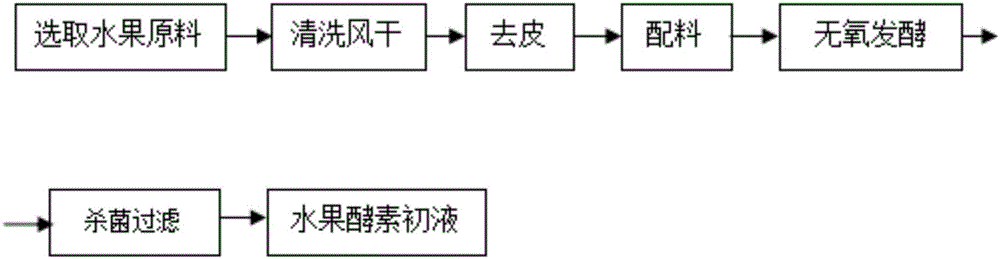

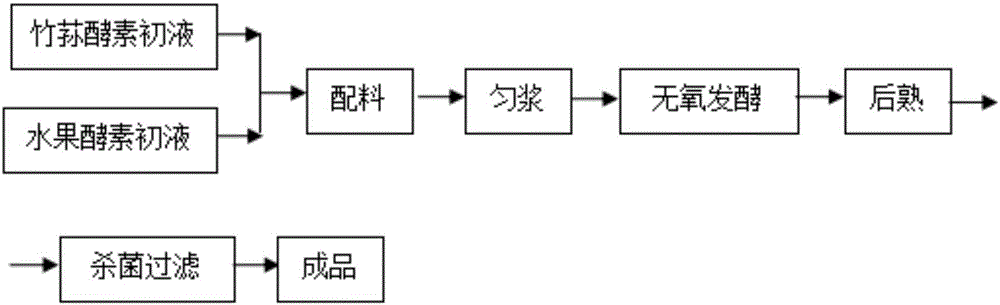

[0036] see Figure 1 to Figure 3 A method for preparing active enzymes compounded with Dictyophora and tropical fruits in the present invention comprises: (1) preparing an initial solution of Dictyophora ferment; (2) preparing an initial solution of tropical fruit enzymes; and (3) preparing a composite active enzyme. in,

[0037] (1) The technological process of preparing the first solution of Dictyophora ferment is:

[0038] Clean the bamboo fungus raw material, blanch it, put it in a sterile room to cool, add Lactobacillus plantarum, green kumquat, white sugar and salt for ingredients, carry out anaerobic fermentation, and use membrane filtration to sterilize or plate heat exchange for high temperature and short-term sterilization , to obtain a golden transparent Dictyophora ferment initial solution. Among them, the blanching treatment is mainly to inhibit the activity of peroxidase (POD) in bamboo fungus and prevent the occurrence of enzymatic browning reaction; after coo...

Embodiment 1

[0045] A method for preparing an active enzyme compounded with bamboo fungus and honey pomelo, comprising:

[0046] (1) Prepare the initial solution of bamboo fungus enzyme:

[0047] Wash the bamboo fungus raw material, and steam blanching, the steam strength is 2.5Pa / g, and the blanching time is 2min.

[0048] Taking steam blanching time and steam intensity A and B factors as a 5*5 two-factor cross experiment, the steam blanching time level is: 1.0min, 1.5min, 2.0min, 2.5min, 3.0min, and the steam intensity level is: 1.5 Pa / g, 2.0Pa / g, 2.5Pa / g, 3.0Pa / g, 3.5Pa / g. The experiment was repeated three times. The retention rate of total sugar in Dictyophora was used as an index to control the quality of Dictyophora, and the inactivation of peroxidase (POD) with high heat resistance was used as a technical parameter index for blanching treatment. Finally, the optimal blanching process parameters were determined as follows: the steam intensity was 2.5Pa / g, and the blanching time was...

Embodiment 2

[0095] A kind of technological process of preparing the compound active enzyme of bamboo fungus and honey pomelo is:

[0096] (1) Prepare the initial solution of bamboo fungus enzyme:

[0097] The raw materials of the bamboo fungus are cleaned and steam blanched. The technical parameters of blanching are: the steam intensity is 2.5Pa / g, and the blanching time is 2min.

[0098] Then put the blanched bamboo fungus into a sterile room to cool, then mix with the bamboo fungus extract, add plantarum lactobacillus, green kumquat, white sugar and salt, calculated by mass percentage, the amount of plantaractobacillus 0.01% of the raw material of Dictyophora, the amount of green kumquat added is 1% of the raw material of Dictyophora, the amount of white sugar added is 25% of the raw material of Dictyophora, the amount of salt added is 3.5% of the raw material of Dictyophora, the amount of Dictyophora dipped The amount of the extract is 70% of the raw material of Dictyophora. The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com