Recovery and shredding processing equipment for waste lithium battery and processing technology thereof

A technology for used lithium batteries and processing equipment, which is applied in battery recycling, waste collector recycling, grain processing, etc., can solve the problems of large-scale production recycling, failure to meet environmental protection requirements, and can not achieve the effect of preventing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with specific embodiments. The purpose of the following words is to illustrate the present invention, rather than limit the protection scope of the present invention.

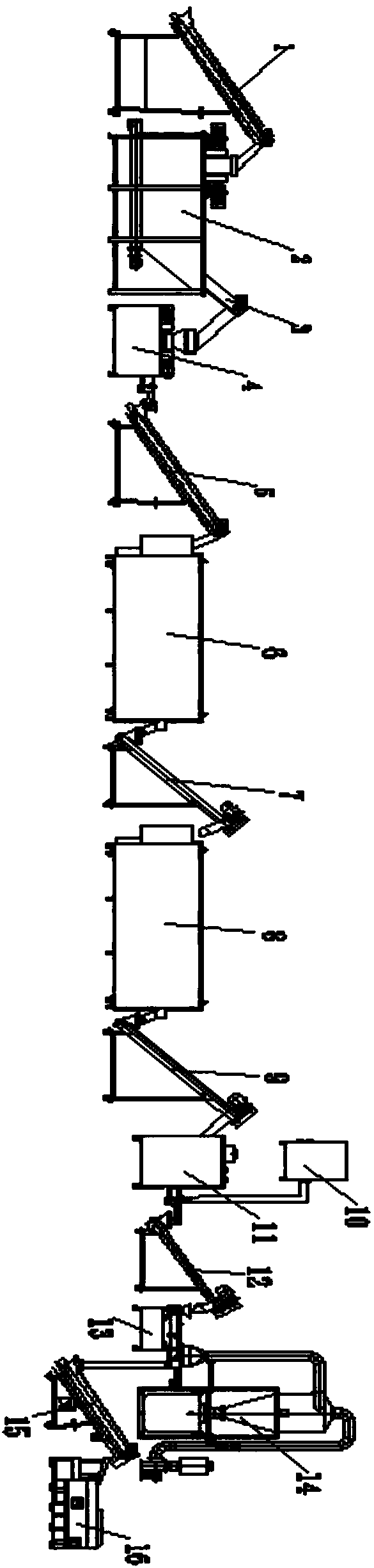

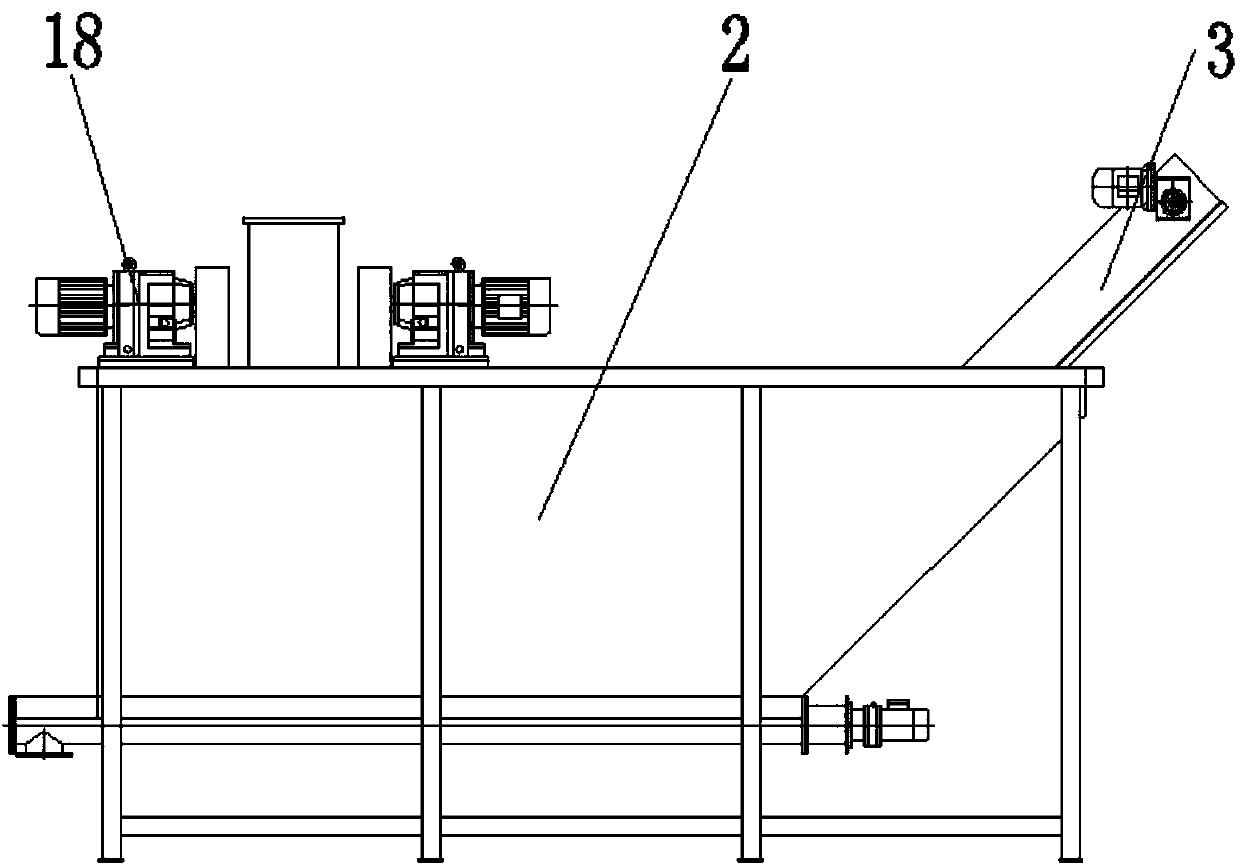

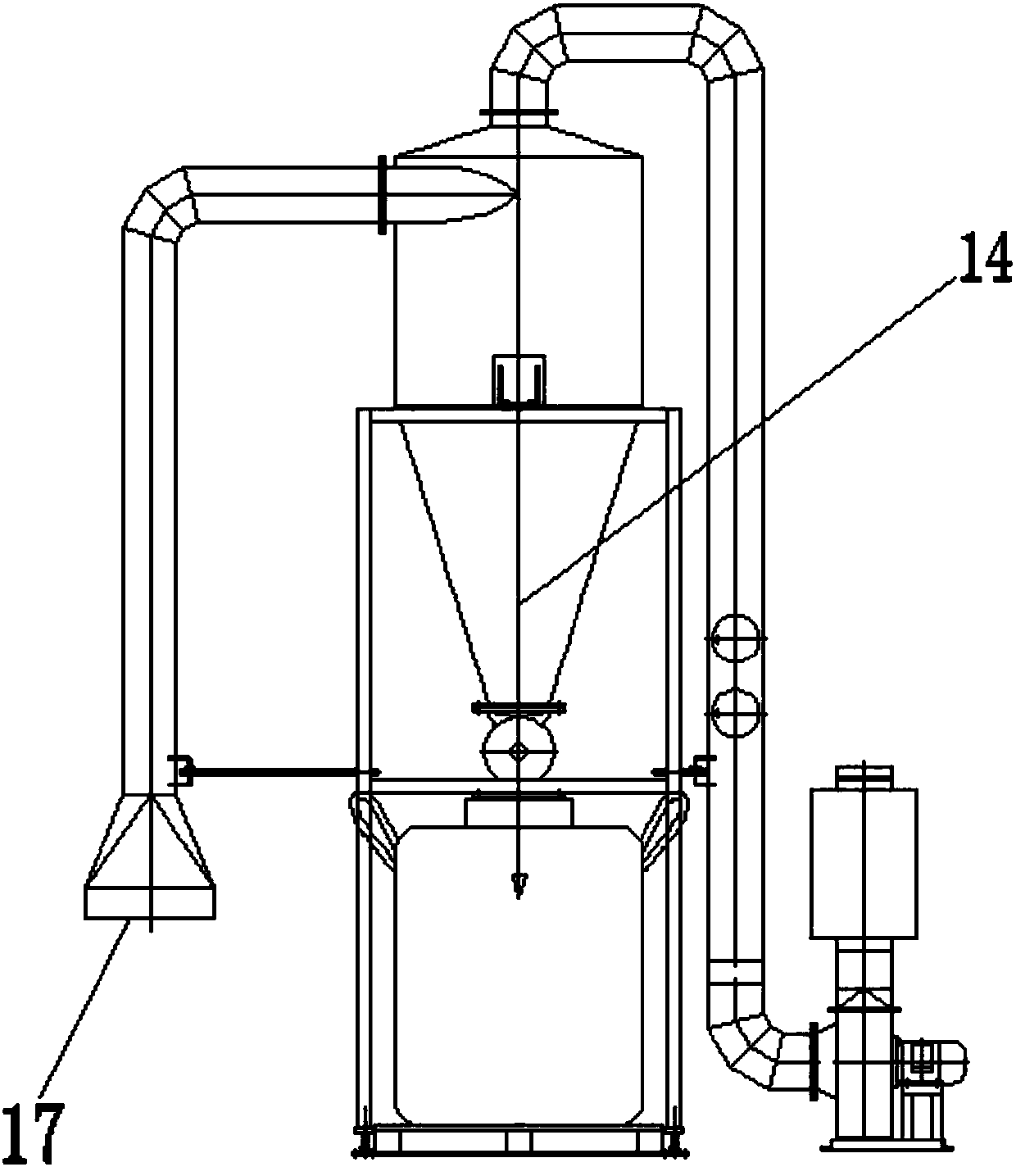

[0036] Such as Figure 1-Figure 5As shown, the present invention can be implemented in the following manner, a recycling and shredding processing equipment for waste lithium batteries, including a physical decomposition equipment 2, a second biaxial shredder 4, a tunnel-type hot air circulation oven, a shredder 11, and a vibrating screening machine 13. The cyclone separator 14 corresponding to the vibration screening machine 13, and the closed conveyor 15. The physical decomposition equipment 2 includes a water tank, a first biaxial shredder and a screw conveyor, and the first biaxial shredder The machine includes a shredding chamber and a drive motor 18, which are respectively placed in the water of the water tank and above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com