Top electrode of reaction tank device for etching equipment

A technology of etching equipment and reaction tank, applied in the field of electrodes, can solve the problems of ceramic spray film peeling, high thermal expansion coefficient, low thermal expansion coefficient, etc., and achieves the effect of reducing equipment cost, not easy to peel off, and tightly combined

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

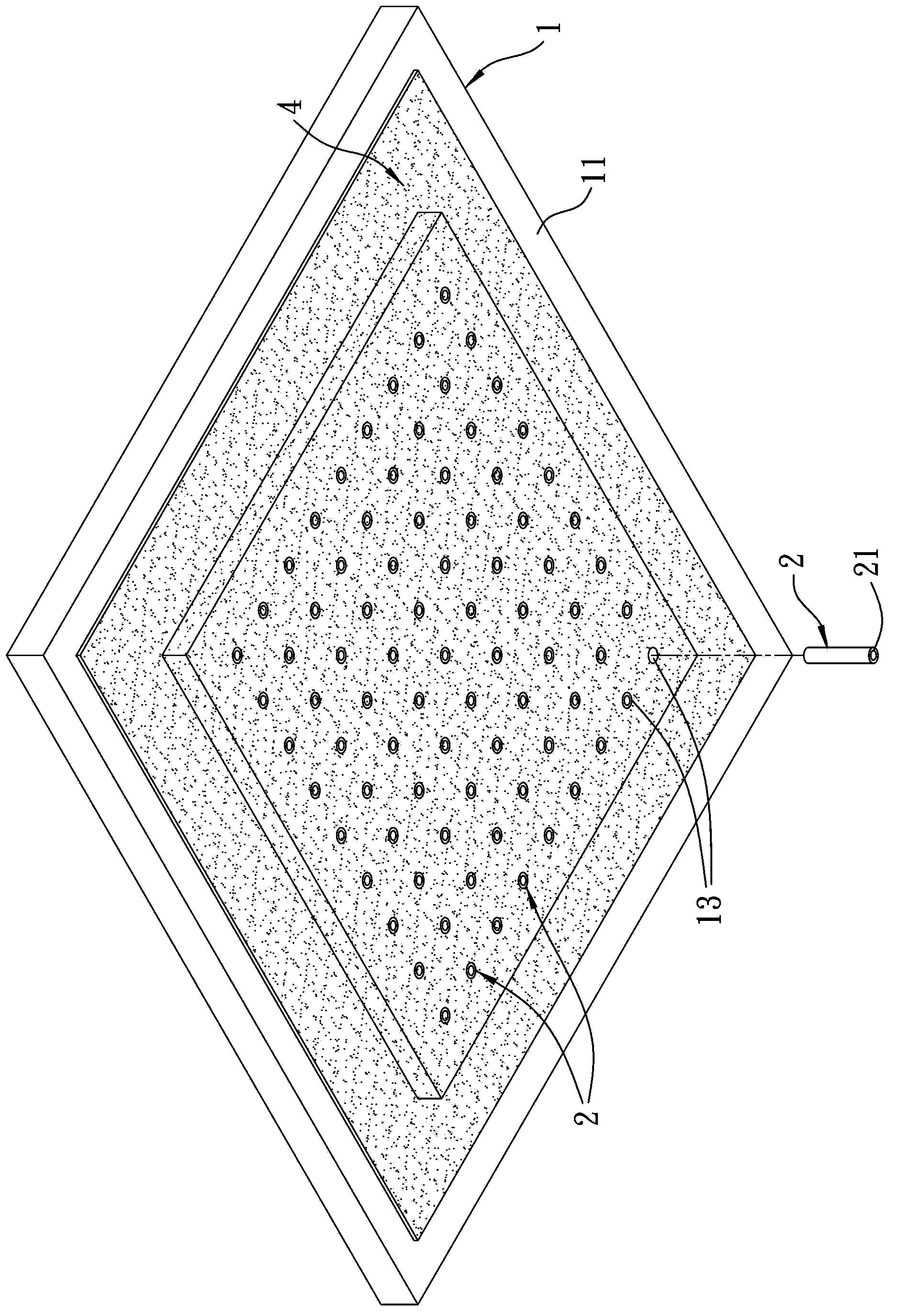

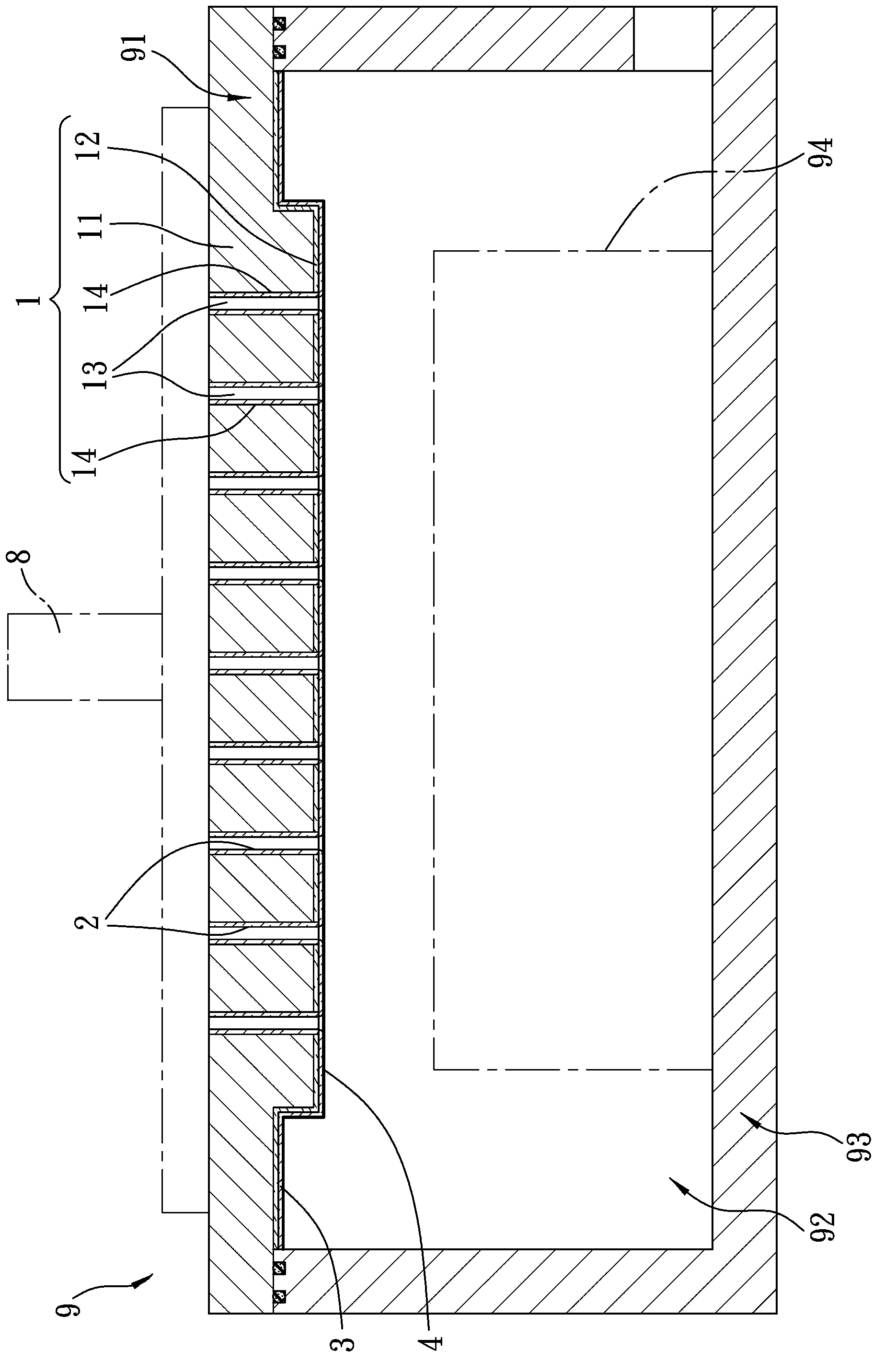

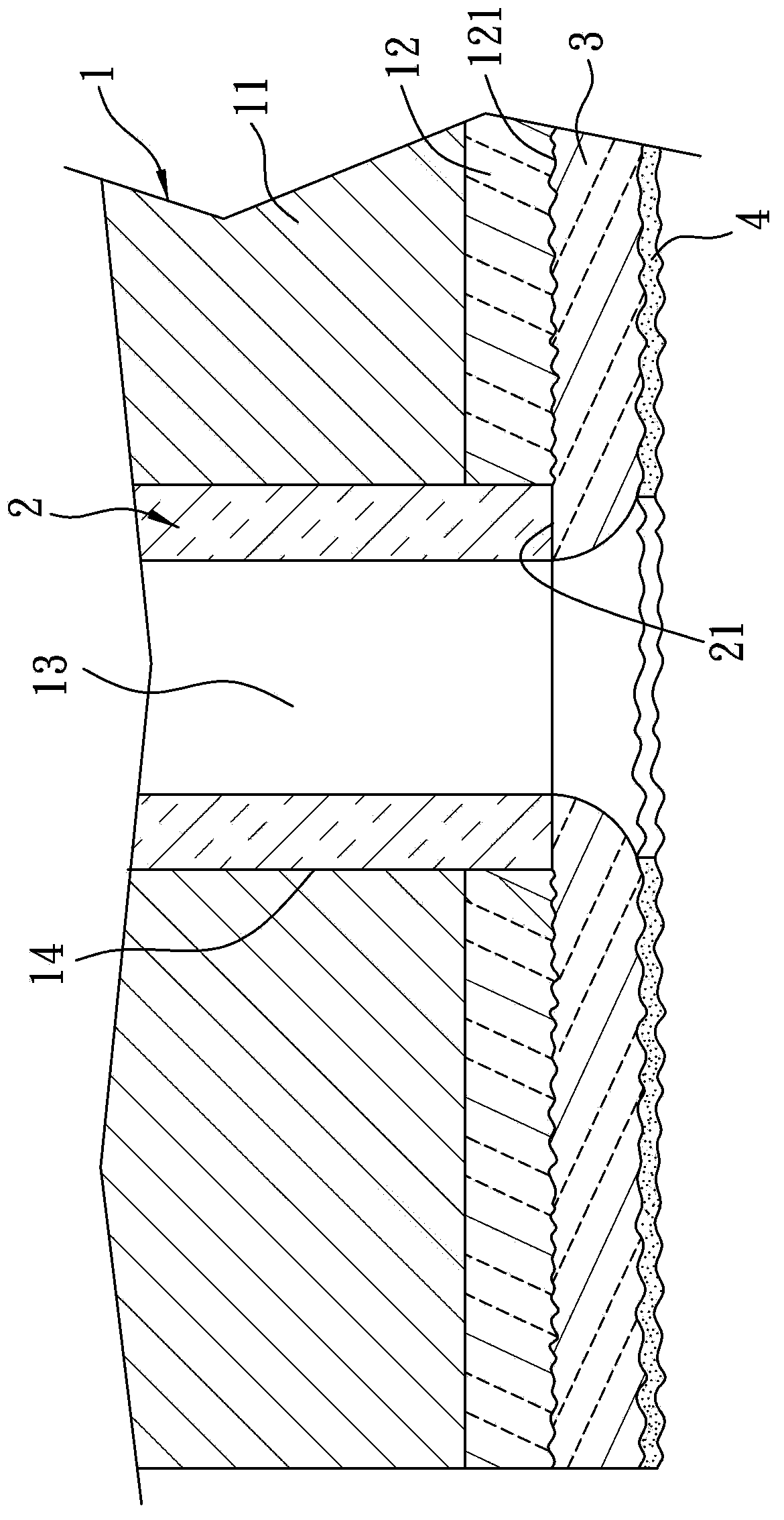

[0024] refer to figure 1 , 2 , 3, a preferred embodiment of the upper electrode 91 of the present invention is one of the components of a reaction tank device 9 of an etching device, and the reaction tank device 9 also includes a reaction chamber that defines a reaction space 92 with an opening facing upwards Seat 93, and a lower electrode 94 installed in the reaction space 92. The upper electrode 91 communicates with a gas input device 8, so that the gas input device 8 can introduce a corrosive gas for etching glass into the reaction space 92, and the corrosive gas can be fluorine or chlorine. Since the operation of the reaction tank device 9 is not the focus of the improvement of the present invention, it will not be described in detail.

[0025] The upper electrode 91 of the present invention is covered on the reaction chamber seat 93 and can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com