Anion natural latex sheet and processing method thereof

A technology of natural latex and processing methods, applied in other home appliances, applications, home appliances, etc., to achieve the effect of promoting human body synthesis and storage of vitamins, simple process operation, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

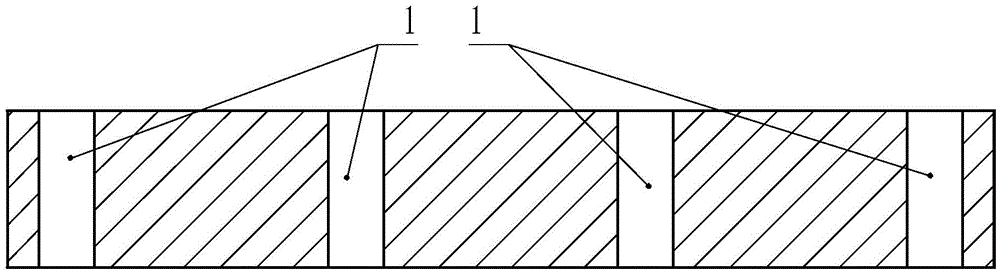

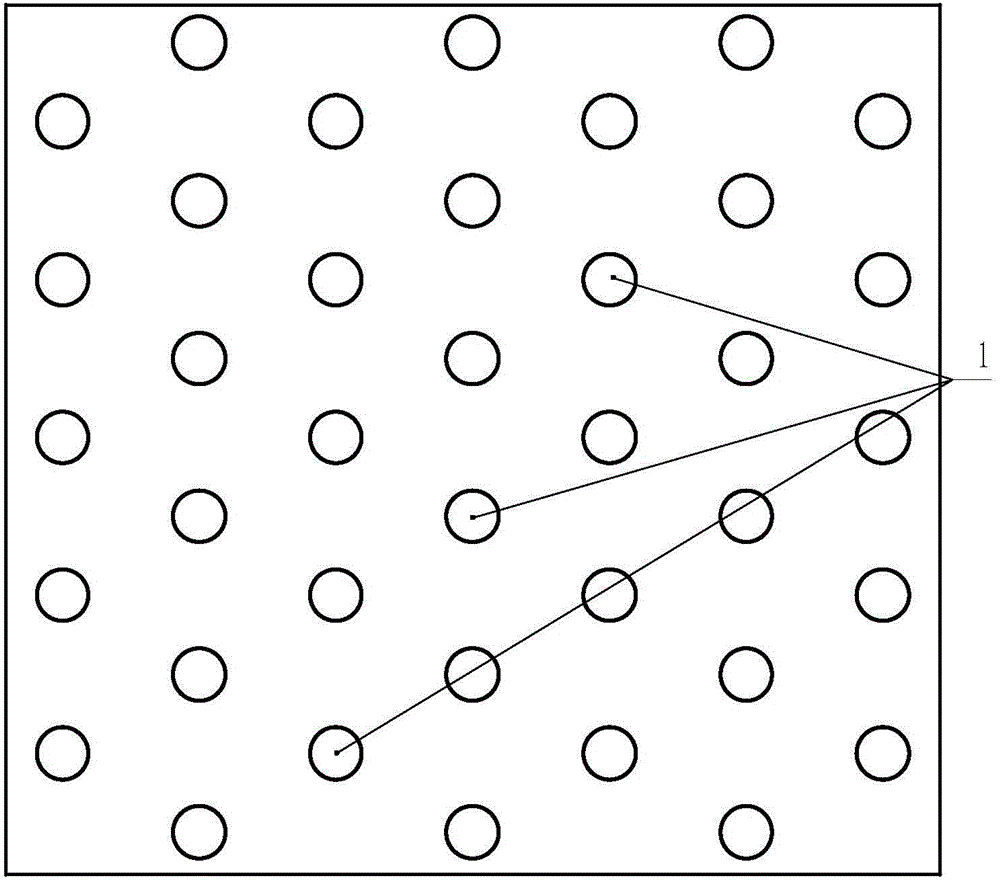

[0024] First take by weight 90 parts of natural latex, 3 parts of negative ion powder, 1 part of sulfur, 1 part of accelerator, 1 part of zinc oxide, and 0.1 part of potassium oleate. Then mix the natural latex, negative ions and potassium oleate for mechanical stirring to make it evenly mixed; after stirring evenly, add sulfur for vulcanization, after 1-3 hours, add zinc oxide, continue stirring for 5-8 hours, Ripening; After the sample is mechanically foamed, air at a certain temperature (60-90°C) is introduced, and under the high-speed stirring and shearing of the machine head, the air and latex are mixed evenly, and the foam is formed in a short time to complete the shape; After steam treatment at 100°C for 1 to 2 hours, it is processed into a shape, cleaned with water, dried, and cooled; several through holes are processed, and the finished product is cut.

Embodiment 2

[0026] First take by weight 100 parts of natural latex, 8 parts of anion, 9 parts of sulfur, 5 parts of accelerator, 6 parts of zinc oxide, and 2 parts of potassium oleate. Then mix the natural latex, negative ions and potassium oleate for mechanical stirring to make it evenly mixed; after stirring evenly, add sulfur for vulcanization, after 1-3 hours, add zinc oxide, continue stirring for 5-8 hours, Ripening; After the sample is mechanically foamed, air at a certain temperature (60-90°C) is introduced, and under the high-speed stirring and shearing of the machine head, the air and latex are mixed evenly, and the foam is formed in a short time to complete the shape; After steam treatment at 100°C for 1 to 2 hours, it is processed into a shape, cleaned with water, dried, and cooled; several through holes are processed, and the finished product is cut.

[0027] Negative ion powder: also known as "air vitamin", not only can promote the synthesis and storage of vitamins in the hum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com