Preparation method for small grainsize polybutadiene latex

A technology of small particle size and latex, which is applied in the field of preparation of small particle size polybutadiene latex, can solve the problems that the particle size of large particle size latex cannot be accurately controlled, the difference in particle size is large, and the heat release of reaction is uneven. Achieve excellent agglomeration effect, short reaction time, uniform reaction heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Polymerization is carried out according to the following components and weight ratios and operating conditions:

[0048] 1), get each component by weight percentage as:

[0049] Butadiene: 38.10

[0050] Styrene: 2.00

[0051] Emulsifier: 1.27

[0052] Tertiary dodecyl mercaptan: 0.18

[0053] Electrolyte: 0.19

[0054] K 2 S 2 o 8 (3%): 0.12

[0055] water: balance

[0056] 2), operating conditions and steps:

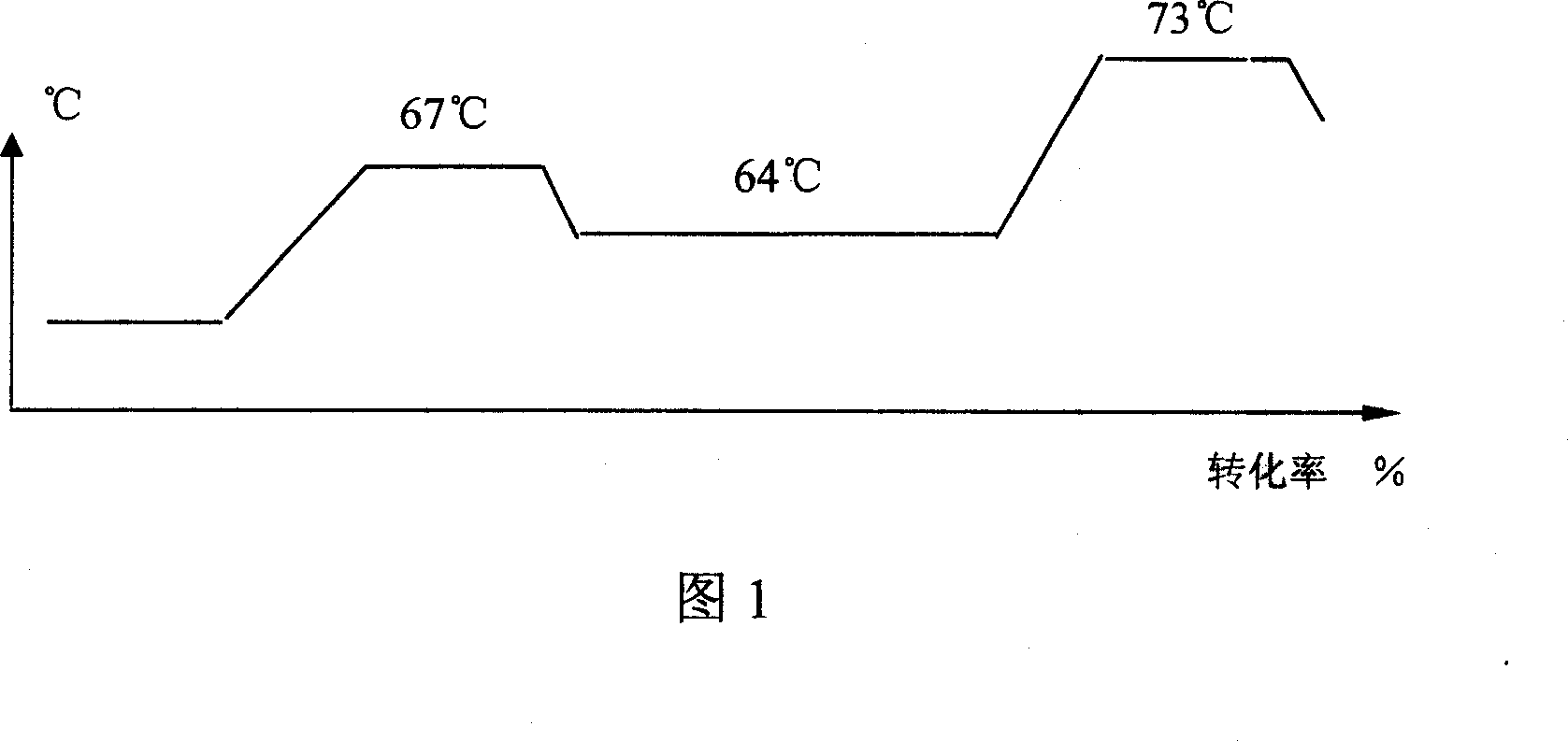

[0057] Mix potassium abietate and potassium oleate at a ratio of 2:1 to make an emulsifier, and the ratio of the composite electrolyte sodium pyrophosphate to potassium carbonate is 1:2. Except for the emulsifier, add all the above components into the reaction kettle , and add 88% emulsifier at the same time; control the reaction temperature according to the saddle-shaped temperature control curve, the early stage is 67°C, the middle stage is 63°C, and the late stage is 73°C. When the conversion rate reaches 30%, the remaining 12% emulsifier is added, ...

Embodiment 2

[0064] Polymerization is carried out according to the following components and weight ratios and operating conditions:

[0065] 1), get each component by weight percentage as:

[0066] Butadiene: 40.10

[0067] Acrylonitrile 0.01

[0068] Emulsifier: 1.27

[0069] tertiary dodecyl mercaptan: 0.18

[0070] Electrolyte: 0.19

[0071] K 2 S 2 o 8 (3%): 0.12

[0072] The balance is water

[0073] 2), operating conditions and steps:

[0074] Mix potassium abietate and potassium oleate in a weight ratio of 6:1 to make an emulsifier, and the ratio of the composite electrolyte sodium pyrophosphate to potassium carbonate is 1:4. Except for the emulsifier, add all the above components to the reaction kettle Add 88% emulsifier at the same time; control the reaction temperature according to the saddle-shaped temperature control curve, the early stage is 63°C, the middle stage is 60°C, and the late stage is 70°C. When the conversion rate reaches 30%, add the remaining 12% emulsif...

Embodiment 3

[0081] 1), select the following components by weight percentage:

[0082] Butadiene: 38.13

[0083] Methyl methacrylate: 6.00

[0084] Emulsifier: 1.18

[0085] tertiary dodecyl mercaptan: 0.18

[0086] Electrolyte: 0.18

[0087] K 2 8 2 o 8 (3%): 0.12

[0088] The balance is water:

[0089] 2) Potassium oleate and potassium abietate are mixed in a weight ratio of 1:0.2 to make an emulsifier. The composite electrolyte EDTA and potassium carbonate are in a weight ratio of 4:1. Except for the emulsifier, all the above components are added to the reaction In the kettle, add 88% emulsifier at the same time; control the reaction temperature according to the saddle-shaped temperature control curve, the early stage is 69°C, the middle stage is 66°C, and the later stage is 75°C. When the conversion rate reaches 30%, add the remaining 12% emulsifier for 7 hours Complete the polymerization reaction.

[0090] 3), the result:

[0091] Response time: 9 hours,

[0092] Latex par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com