Efficient laundry detergent and preparation method thereof

A high-efficiency laundry detergent and solution technology is applied in the field of daily chemicals to achieve the effects of high efficiency and stability of products, simple process operation and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, a kind of high-efficiency laundry detergent

[0037] Described high-efficiency laundry detergent is made up of following components and mass percentage thereof:

[0038] 5% sodium sulfate of fatty alcohol polyoxyethylene ether with a mass concentration of 70%, 3% of linear alkylbenzene sulfonic acid, 3% of fatty alcohol polyoxyethylene ether, and 35% of cocamidopropyl betaine 3%, 3% potassium laurate aqueous solution with a mass concentration of 17%, 3% potassium oleate aqueous solution with a mass concentration of 5%, sodium hydroxide 1%, compound enzyme 0.1%, preservative 0.05%, ethylenediaminetetraacetic acid 0.1% disodium, 0.05% citric acid, 0.5% sodium chloride, 0.15% essence and 78.05% deionized water; the preservative consists of 5-chloro-2-methyl-4-isothiazolin-3-one and 2-Methyl-4-isothiazolin-3-one is composed in a mass ratio of 3:10.

[0039] The compound enzyme is composed of protease, lipase, amylase and cellulase in a mass ratio of 4:4:6:3....

Embodiment 2

[0049] Embodiment 2, a kind of high-efficiency laundry detergent

[0050] Described high-efficiency laundry detergent is made up of following components and mass percentage thereof:

[0051] Mass concentration is 70% fatty alcohol polyoxyethylene ether sodium sulfate 20%, linear alkylbenzene sulfonic acid 15%, fatty alcohol polyoxyethylene ether 6%, mass concentration is 35% cocamidopropyl betaine 8%, 10% potassium laurate aqueous solution with a mass concentration of 17%, 10% potassium oleate aqueous solution with a mass concentration of 5%, sodium hydroxide 10%, compound enzyme 2%, preservative 0.2%, ethylenediaminetetraacetic acid 0.5% disodium, 0.5% citric acid, 3% sodium chloride, 0.5% essence and 14.3% deionized water; the preservative consists of 5-chloro-2-methyl-4-isothiazolin-3-one and 2-Methyl-4-isothiazolin-3-one is composed of mass ratio 3-5:8-10.

[0052] The compound enzyme is composed of protease, lipase, amylase and cellulase in a mass ratio of 7:2:4:1.

[...

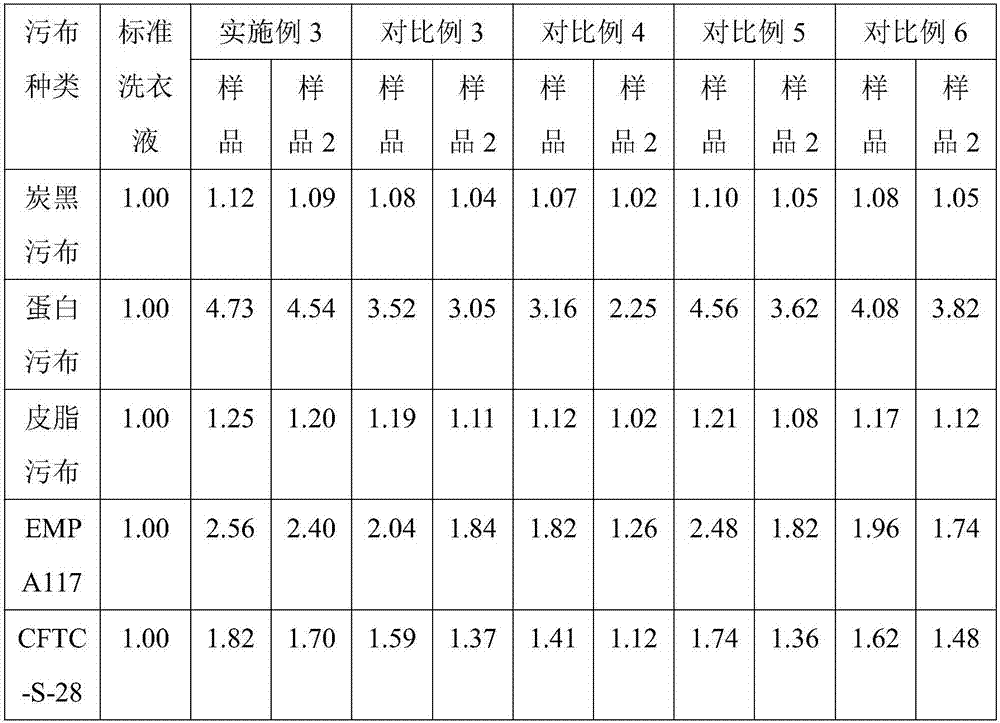

Embodiment 3

[0062] Embodiment 3, a kind of high-efficiency laundry detergent

[0063] Described high-efficiency laundry detergent is made up of following components and mass percentage thereof:

[0064] Mass concentration is 70% fatty alcohol polyoxyethylene ether sodium sulfate 10%, linear alkylbenzene sulfonic acid 5%, fatty alcohol polyoxyethylene ether 4%, mass concentration is 35% cocamidopropyl betaine 5%, 6% potassium laurate aqueous solution with a mass concentration of 17%, 6% potassium oleate aqueous solution with a mass concentration of 5%, sodium hydroxide 2%, compound enzyme 0.5%, preservative 0.1%, ethylenediaminetetraacetic acid Disodium 0.1%, citric acid 0.1%, sodium chloride 1.5%, essence 0.35% and deionized water 59.35%; The preservative consists of 5-chloro-2-methyl-4-isothiazolin-3-one and 2-Methyl-4-isothiazolin-3-one is composed in a mass ratio of 4:9.

[0065] The compound enzyme is composed of protease, lipase, amylase and cellulase in a mass ratio of 5:3:5:2.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com