Low content nitrile cross-linked powdery acrylonitrile butadiene preparation method

A technology of powder nitrile-butadiene rubber and a production method, which is applied in the production field of cross-linked powder nitrile-butadiene rubber with low nitrile content, can solve problems such as immature polymerization method, and achieve stable performance indicators, good isolation effect and high drying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

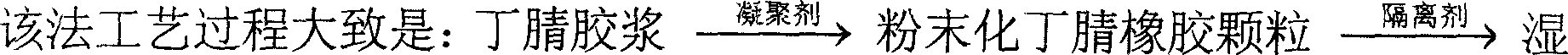

Method used

Image

Examples

Embodiment 1

[0039] A: Preparation of nitrile mortar: firstly, vacuumize the polymerization kettle, put in 180 parts of soft water, 5 parts of fatty acid potassium-potassium oleate compound emulsifier in a ratio of 1:0.5, 0.6 parts of diffusing agent NF, tert-dodecylsulfur 0.5 parts of alcohol, 28 parts of acrylonitrile, 0.4 parts of initiator (potassium persulfate), stop vacuuming, add 72 parts of butadiene; heat up to 29±1°C, when the conversion rate reaches 60%, heat up to 47±1 ℃, when the conversion rate reaches above 95%, add 0.2 parts of sodium formam to terminate the reaction, and send the glue into the degasser for flashing to remove unreacted butadiene and acrylonitrile. The flashing degassing conditions are: temperature 60~ 70℃, vacuum degree -0.04~-0.06MPa, degassing time 2~3hr.

[0040] The indicators of the obtained glue are as follows:

[0041] Solid content: 35.6%; PH value: 10.7 Structural gel content: 78%;

[0042] Mooney viscosity : 125; bound acrylonitrile: 26.2%

...

Embodiment 2

[0049] When adjusting the composite consumption of potassium fatty acid-potassium oleate in the nitrile mortar preparation process in embodiment 1 to 6 parts, without diffusing agent NF, acrylonitrile is adjusted to 35 parts by 28 parts, initiator (potassium persulfate) Adjust 0.3 part by 0.4 part, add butadiene and adjust to 65 parts by 72 parts, other process formula is the same as embodiment 1, and gained product index is still in the control range shown in table 2. Its indicators are as follows:

[0050] Solid content: 35.4%; PH value: 10.6 Structural gel content: 82%;

[0051] Mooney viscosity : 130; bound acrylonitrile: 32.7%

Embodiment 3

[0053] The consumption of the butadiene in the butadiene mortar preparation process in the embodiment 1 is transferred to 70 parts by 72 parts, and acrylonitrile is transferred to 30 parts by 28 parts, and initiator potassium persulfate is changed into hydrogen peroxide Dicumyl-ferrous sulfate was used as an initiator to react at a temperature of 5-8° C., and the other technological formulas were the same as in Example 1, and the index of the obtained product was still within the control range shown in Table 2. Its indicators are as follows:

[0054] Solid content: 35.9%; PH value: 10.6 Structural gel content: 76%; Mooney viscosity : 110; bound acrylonitrile: 26.2%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com