Nutritional skin-care skin-moisturizing powder-containing polyvinyl chloride (PVC) glove and manufacturing method thereof

A production method and glove technology, applied in gloves, clothing, applications, etc., can solve skin damage and other problems, and achieve the effect of flexible use, strong thermal stability, good nutrition, skin care and moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

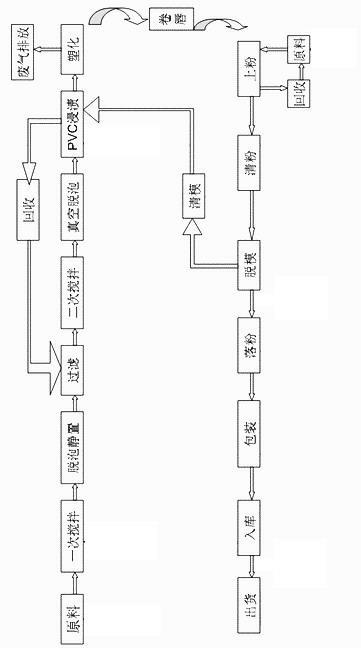

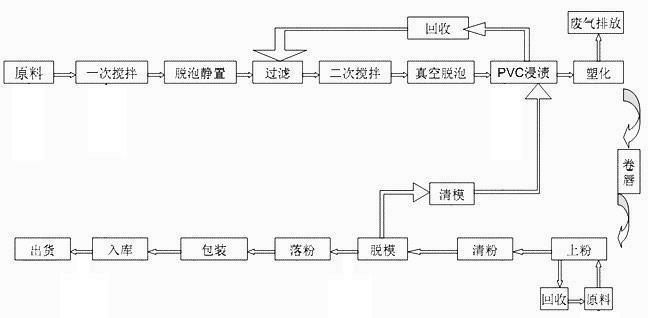

[0029] The preparation method of powdered PVC gloves for nutrition, skin care and moisturizing of the present invention comprises the following steps:

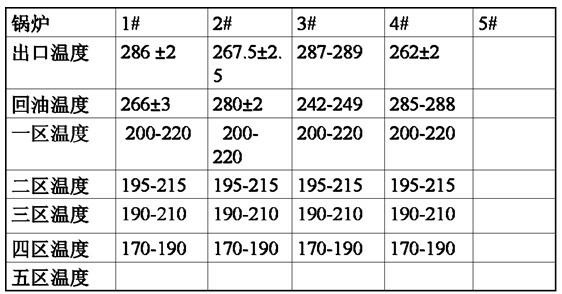

[0030] (1) Ingredients: PVC paste resin, plasticizer (DOP\DINP), viscosity reducer (solvent oil), heat stabilizer, collagen, weighed according to a certain proportion, fully mixed, poured into the mixing tank and stirred evenly Blend into a lotion. Calcium-zinc composite stabilizer is used as heat stabilizer, and viscosity reducer is dearomatized solvent oil or 70 # Fragrance spirit. The ratio of raw materials is: PVC paste resin powder 100㎏, DINP 32㎏, calcium-zinc composite stabilizer 1.2㎏, viscosity reducer 32㎏, namely 1:0.32:0.012:0.32, collagen 0.5㎏, collagen is prepared in the material Add after stirring. Vitamin E is 0.3 kg. Stirring time is 2.5 hours in winter and 90 minutes in summer, and the rotation speed is ≥1200 rpm (Use the shear force of high-speed rotation to disperse PVC powder so that it can be well mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com