Natural emulsion composite slurry and preparation method thereof, protection gloves and preparation method thereof

A technology of natural latex and composite slurry, which is applied in gloves, other household utensils, clothing, etc., can solve the comprehensive performance damage of tear resistance, wear resistance, cut resistance and puncture resistance, weakening of rubber hydrocarbon binding ability, aging performance Relatively large impact and other issues, to achieve the effect of high industrial application value, soft texture, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

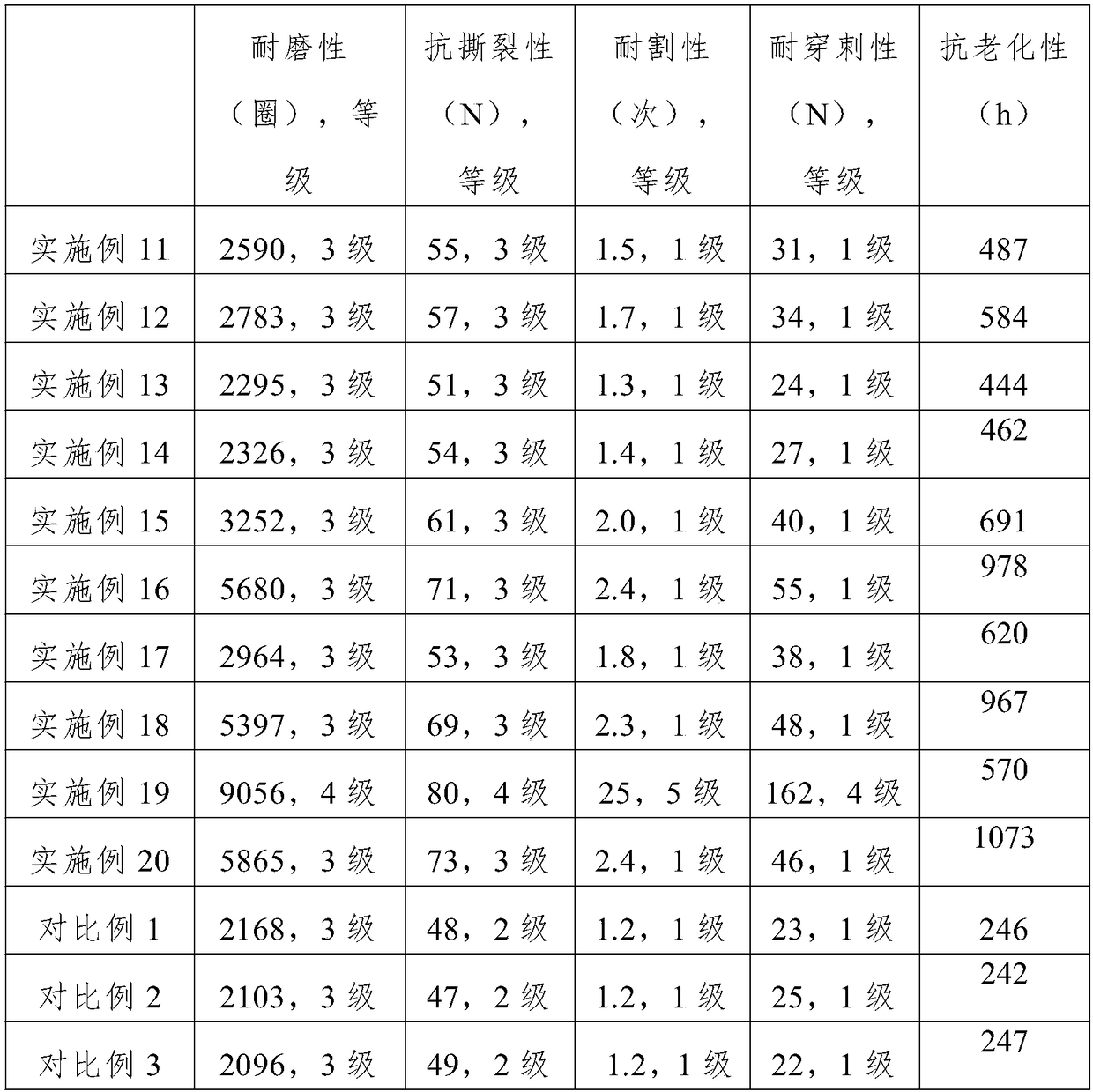

Examples

preparation example Construction

[0029] The specific embodiment part of the present invention provides a kind of preparation method of natural latex composite slurry, and this method comprises the following steps:

[0030] (1) Adopt cold water dilution to prepare the thermosensitizer of required mass concentration (hereinafter referred to as the thermosensitizer diluted by cold water), and adopt vulcanization system to carry out pre-vulcanization treatment to natural latex to obtain pre-vulcanized natural latex.

[0031] In the present invention, the heat-sensitive agent (hereinafter referred to as heat-sensitive agent) before cold water dilution is selected from one or more combinations of polyvinyl methyl ether, polyether polyoxymethylene acetal, and polypropylene glycol. The sensitizer acts as a stabilizer when the temperature of the latex is low, and when the temperature is high, it will solidify rapidly when it reaches the cloud point of the thermal sensitizer, causing the latex to solidify, so that the l...

Embodiment 1

[0050] A preparation method for natural latex composite slurry, comprising the following steps:

[0051] (1) Dilute with cold water to prepare polyvinyl methyl ether with a mass concentration of 20%, and use a sulfur vulcanization system to pre-vulcanize the natural latex to obtain pre-vulcanized natural latex.

[0052] Among them, the pre-vulcanized natural rubber latex is a concentrated natural rubber latex with a dry rubber content of 60% and an ammonia content of 0.7% as a raw material. It is composed of sulfur, zinc diethyldithiocarbamate and zinc oxide. The sulfur vulcanization system of 0.8%, 0.4% and 0.4% of the dry milk content of natural rubber latex is made by vulcanizing at 60°C for 2 hours.

[0053] (2) The pre-vulcanized natural rubber latex in the step (1) is subjected to constant temperature treatment, and after the temperature is constant at 20° C., in the stirring process, slowly add polyvinyl methyl ether diluted with cold water in the step (1), The added w...

Embodiment 2

[0055] A preparation method for natural latex composite slurry, comprising the following steps:

[0056] (1) Dilute with cold water to prepare polyvinyl methyl ether with a mass concentration of 20%, and use a sulfur vulcanization system to pre-vulcanize the natural latex to obtain pre-vulcanized natural latex.

[0057] Among them, the pre-vulcanized natural rubber latex is a concentrated natural rubber latex with a dry rubber content of 60% and an ammonia content of 0.7% as a raw material. It is composed of sulfur, zinc diethyldithiocarbamate and zinc oxide. The sulfur vulcanization system of 0.8%, 0.4% and 0.4% of the dry milk content of natural rubber latex is made by vulcanizing at 60°C for 2 hours.

[0058] (2) The pre-vulcanized natural rubber latex in the step (1) is subjected to constant temperature treatment, and after the temperature is constant at 20° C., in the stirring process, slowly add polyvinyl methyl ether diluted with cold water in the step (1), The added w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com