Asphalt foaming agent and preparation method thereof

A technology of foaming agent and asphalt, which is applied in the field of asphalt foaming agent and its preparation, can solve the problems that the foaming agent cannot meet the construction requirements and the adjustment means are limited, and achieve the improvement of expansion rate, stability, and high and low temperature performance of asphalt Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Mix natural latex and industrial latex (styrene-butadiene latex) at a mass ratio of 100:0, with a solid content of 35%, at a temperature of 10-40°C, in a reaction kettle, and stir at a speed of 30-50 rpm to obtain asphalt foaming agent.

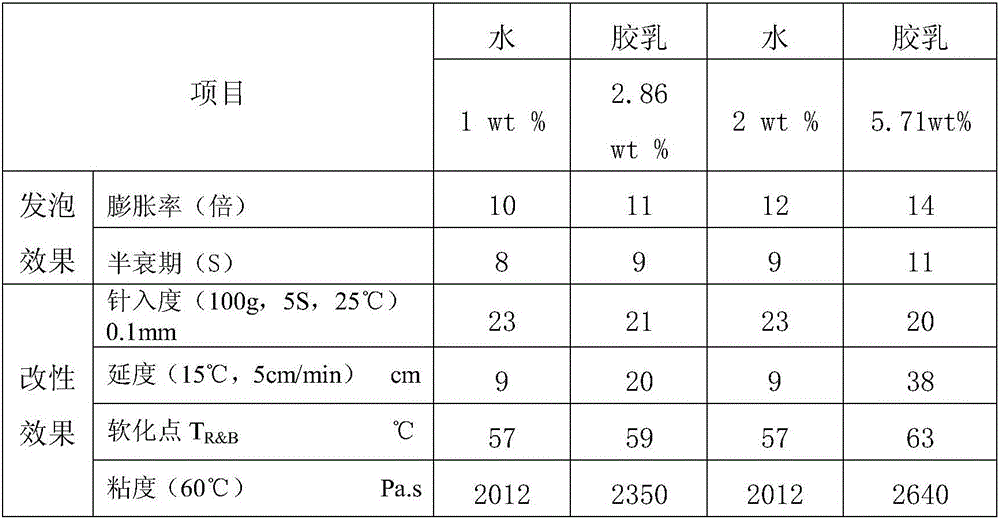

[0015] Add the foaming agent to the 0.1mm petroleum asphalt with a penetration of 20-40 (25°C, 100g, 5s), and when the addition amount is 2.86wt%, the expansion rate and half-life of the asphalt foam are compared with the reference results in Table 1 , the main indicators of asphalt and modified asphalt are shown in Table 1; when the addition amount is 5.71wt%, the expansion rate and half-life of asphalt foaming are compared with the reference results in Table 1, and the main indicators of asphalt and modified asphalt are shown in Table 1.

[0016] Table 1

[0017]

Embodiment 2

[0019] Mix natural latex and industrial latex (styrene-butadiene latex) at a mass ratio of 7:3, with a solid content of 50%, at a temperature of 10-40°C, in a reaction kettle, and stir at a speed of 30-50 rpm to obtain asphalt foam agent.

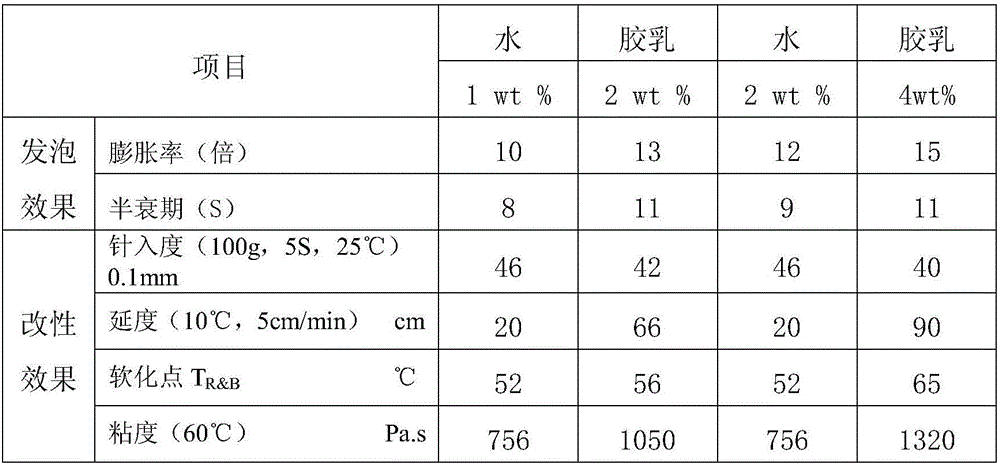

[0020] The foaming agent is added to the 0.1mm petroleum asphalt with a penetration of 40-60 (25°C, 100g, 5s), and when the addition amount is 2wt%, the expansion rate and half-life results of the asphalt foam are compared with the reference in Table 2, The main indicators of asphalt and modified asphalt are shown in Table 2; when the addition amount is 4wt%, the expansion rate and half-life of asphalt foam are compared with the reference in Table 2, and the main indicators of asphalt and modified asphalt are shown in Table 2.

[0021] Table 2

[0022]

Embodiment 3

[0024] Mix natural rubber latex and industrial latex (nitrile latex) at a mass ratio of 6:4, with a solid content of 55%, at a temperature of 10-40 ° C, in a reaction kettle, and stir at a speed of 30-50 rpm to obtain asphalt foaming agent.

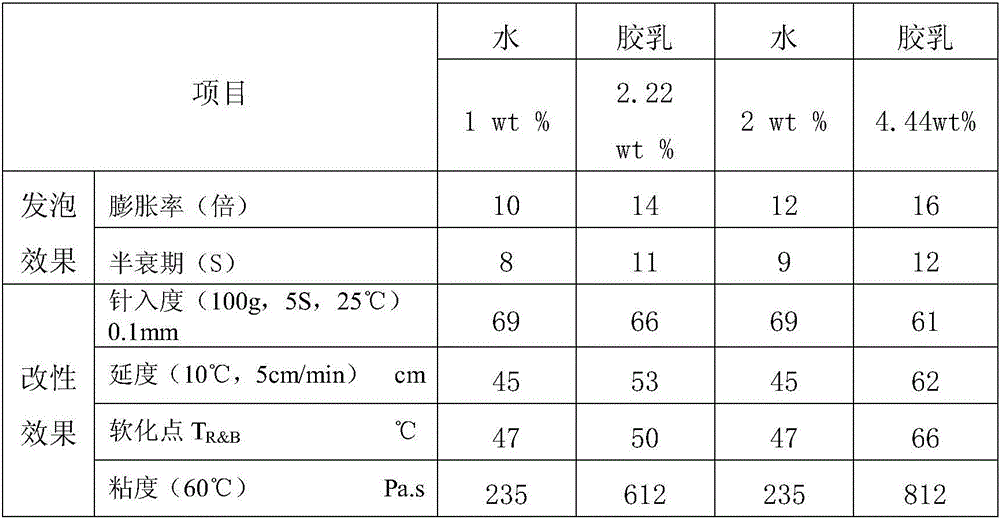

[0025] Add foaming agent to 0.1mm petroleum asphalt with a penetration of 60-80 (25°C, 100g, 5s), and when the amount added is 2.22wt%, the expansion rate and half-life of the asphalt foam are compared with the reference results in Table 3 , the main indicators of asphalt and modified asphalt are shown in Table 3; when the addition amount is 4.44wt%, the expansion rate and half-life of asphalt foaming are compared with the reference results in Table 3, and the main indicators of asphalt and modified asphalt are shown in Table 3.

[0026] table 3

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com