Preparation method of high wear-resistant compounded latex gloves

A latex glove, high wear-resistant technology, applied in gloves, clothing, applications, etc., can solve the problems of poor wear-resistant performance and short service life of gloves, and achieve the effect of increasing service life, solving non-abrasion resistance and good softness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

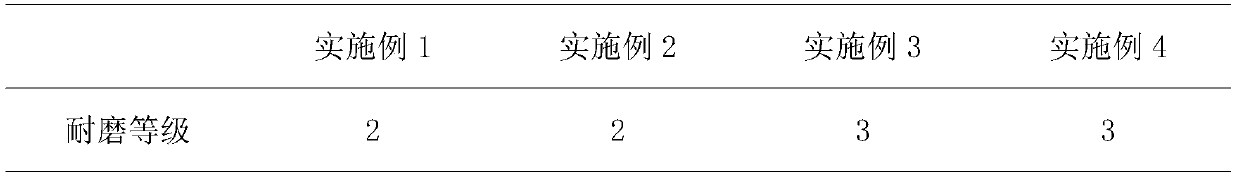

Examples

Embodiment 1

[0019] A preparation method for high wear-resistant latex gloves, comprising the following steps:

[0020] S1. Natural latex 72.8%, nitrile latex 0%, styrene-butadiene latex 0%, potassium hydroxide 1%, casein 2%, sulfur 0.8%, accelerator BZ 1.2%, zinc oxide 5%, anti- Stir 1.8% of oxygen agent, 4.8% of paraffin wax and 3.6% of black pigment evenly to prepare compound latex, and let it stand for 24 hours;

[0021] S2. Add 5% hydroxyethyl cellulose to the latex, and use a rotor viscometer to monitor the latex thickening to 500mPa s;

[0022] S3. Put the palm of the glove liner on the mold, preheat it at 40°C for 10 minutes, immerse it in the anti-seepage agent and air-dry it for 100 seconds, and immerse the glove liner in the compound latex treated in step S2 to form rubber coating;

[0023] S4. After the rubber coating is air-dried, apply anti-slip treatment on its surface, dry it in an oven at 40°C for 15 minutes, then soak it in clean water at 40°C for 80 minutes;

[0024] ...

Embodiment 2

[0026] A preparation method for high wear-resistant latex gloves, comprising the following steps:

[0027] S1. 62.8% of natural latex, 5% of nitrile latex, 5% of styrene-butadiene latex, 3% of potassium hydroxide, 0.8% of casein, 1.2% of sulfur, 5% of accelerator BZ, 1.8% of zinc oxide, anti- Stir 0.6% of oxygen agent, 8% of paraffin wax and 3.6% of black pigment evenly to prepare compound latex, and let it stand for 36 hours;

[0028] S2. Add 6% hydroxyethyl cellulose to the latex, and use a rotor viscometer to monitor the latex thickening to 1000mPa s;

[0029] S3. Put the palm of the glove liner on the mold, preheat it at 50°C for 15 minutes, immerse it in the anti-seepage agent and air-dry it for 100 seconds, and immerse the glove liner in the compound latex treated in step S2 to form rubber coating;

[0030] S4. After the rubber coating is air-dried, apply anti-slip treatment on its surface, dry it in an oven at 45°C for 18 minutes, then soak it in clean water at 45°C f...

Embodiment 3

[0033] A preparation method for high wear-resistant latex gloves, comprising the following steps:

[0034] S1. According to the percentage by weight, 52.8% of natural latex, 10% of nitrile latex, 10% of styrene-butadiene latex, 3% of potassium hydroxide, 0.8% of casein, 1.2% of sulfur, 5% of accelerator BZ, 1.8% of zinc oxide, anti- Stir 0.6% of oxygen agent, 8% of paraffin wax and 3.6% of black pigment evenly to prepare compound latex, and let it stand for 36 hours;

[0035] S2. Add 6% hydroxyethyl cellulose to the latex, and use a rotor viscometer to monitor the latex thickening to 1500mPa s;

[0036] S3. Put the palm of the glove liner on the mold, preheat it at 50°C for 15 minutes, immerse it in the anti-seepage agent and air-dry it for 100 seconds, and immerse the glove liner in the compound latex treated in step S2 to form rubber coating;

[0037] S4. After the rubber coating is air-dried, apply anti-slip treatment on its surface, dry it in an oven at 40-50°C for 15-20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com