Alkylated glass mold for producing waterborne polyurethane condoms and waterborne polyurethane condom production method

A technology of water-based polyurethane and glass moulds, which can be applied to household appliances, other household appliances, applications, etc., can solve the problems of large-scale industrial production without practical significance, and achieve the effect of mature production technology, easy curling, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

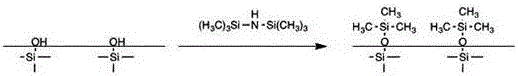

[0032] Alkylation of glass molds: commercially available natural latex condom glass molds were soaked in cleaning solution for 2 hours, rinsed with distilled water, dried at 110°C, and then immersed in hexamethyldisilamine with a concentration of 10wt%. Alkanes in chloroform solution, soaked at room temperature for 12 hours, taken out, rinsed with chloroform, and then dried at 110°C to obtain an alkylated glass mold, which was used to determine the detection liquid with known surface energy parameters by contact angle measurement (two Sub-distilled water, glycerin, formamide, diiodomethane, ethylene glycol) on the mold surface contact angle, using Young's equation to calculate its surface energy as 34 mJ / m 2 , for specific operations, please refer to "Measurement of Surface Energy of Polymer Materials by Contact Angle Method", Wang Hui et al., Journal of Central South University (Natural Science Edition), 2006, Volume 37, Issue 5.

Embodiment 2

[0034] Alkylation of glass molds: commercially available natural latex condom glass molds, soaked in cleaning solution for 2 hours, rinsed with distilled water, dried at 110°C, and then immersed in dimethyldichlorosilane with a concentration of 10wt%. chloroform solution, soaked at room temperature for 12 hours, taken out, rinsed with chloroform, and then dried at 110 ° C to obtain an alkylated glass mold, which was used to measure the detection liquid with known surface energy parameters by contact angle measurement (secondary The contact angle of distilled water, glycerin, formamide, diiodomethane, ethylene glycol) on the surface of the mold, the surface energy calculated by Young's equation is 35 mJ / m 2 .

Embodiment 3

[0036] Surface tension adjustment of water-based polyurethane: first add thickener, defoamer, film-forming aid, etc. to commercially available 35% water-based polyurethane according to conventional dosage to make water-based polyurethane emulsion, and then add 0.2wt% polyether to the emulsion Modified siloxane (BYK-310) (U.S. FDA 21 CFR (Food and Drugs) Section 175.300 allows use in indirect food additives, coatings and adhesives in contact with food) to adjust the surface tension of the emulsion. The surface tension of the liquid water-based polyurethane emulsion was determined by the pull-off method to be 32 mN / m.

[0037] Water-based polyurethane condom molding process: directly immerse the alkylated glass mold prepared in Example 1 into the above-mentioned water-based polyurethane emulsion, lift it out at a slow speed, rotate the mold to keep the coating even, transfer it to the drying tunnel for drying, and if necessary, carry out two One or more times of direct immersion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface energy | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com