Preparation method of nitrogen-doped hollow porous carbon

A porous carbon material and nitrogen-doped technology, which is applied in the preparation/purification of carbon, can solve problems such as unreasonable pore size distribution, damage to reaction vessels, and complicated and lengthy environments, and achieve obvious environmental protection benefits, avoiding environmental hazards, The effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

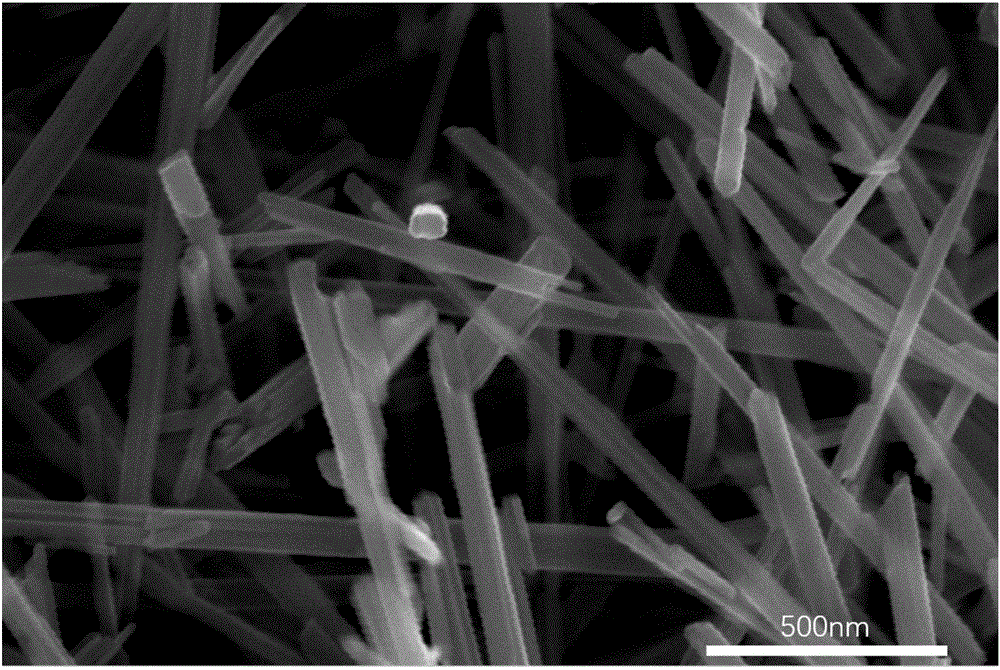

[0029] Take 0.7g KMnO 4 , 1.4 g MnSO 4 , dissolved in 70ml of water. The solution was poured into a hydrothermal kettle and kept at 150° C. for 12 hours. After it was cooled to room temperature, the obtained product was washed with suction and dried at 60° C. The brown powder obtained at this time is the attached figure 1 Manganese dioxide nanotubes are shown.

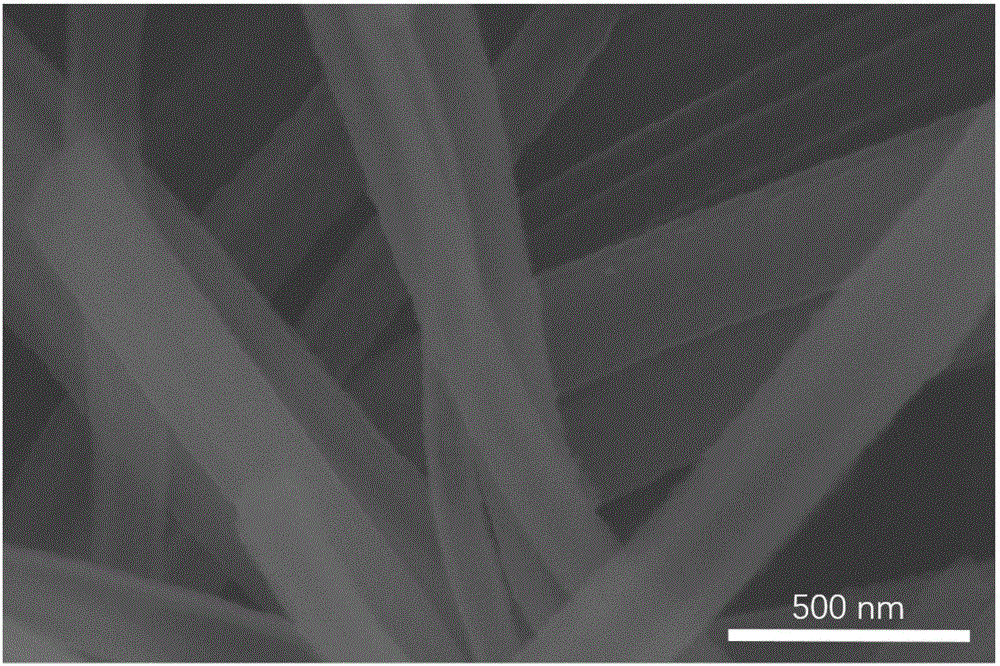

[0030] Take 400 mg of the prepared manganese dioxide nanotubes, 0.152 ml of aniline, and 0.116 ml of pyrrole, add them into 180 ml of water, stir for 20 min, put the solution in a refrigerator (3-5°C) and freeze for 30 min, take it out and add 1 ml of H 2 SO 4 , stirred for 0.5min, put it in a refrigerator (3-5°C) for 8h reaction, suction filtered the product until the filtrate was neutral, and dried at 60°C. The black product obtained at this time is the attached figure 2 Intermediates shown.

[0031] Take 400 mg of the intermediate product, place it in a tube furnace, and raise the temperature to 900 °C at a ...

Embodiment 2

[0034] Take 0.7g KMnO 4 , 1.5g MnSO 4 , dissolved in 70ml of water. The solution was poured into a hydrothermal kettle and kept at 120° C. for 5 hours. After it was cooled to room temperature, the obtained product was washed with suction and dried at 60° C. get attached at this time Figure 5 The three-dimensional manganese dioxide shown.

[0035] Take 200mg of manganese dioxide, 0.38ml of aniline, and 0.29ml of pyrrole, add them into 60ml of water, stir for 20min, put the solution in the refrigerator (3-5℃) and freeze for 30min, take it out and add 15ml of pre-frozen containing 1ml Concentrated H 2 SO 4 The aqueous solution was stirred for 0.5 min, put into the refrigerator (3-5°C) and reacted for 8h, the product was suction filtered until the filtrate was neutral, and dried at 60°C to obtain an intermediate product.

[0036] Take 200 mg of the intermediate product, place it in a tube furnace, and raise the temperature to 900°C at a rate of 5°C / min under a nitrogen atmo...

Embodiment 3

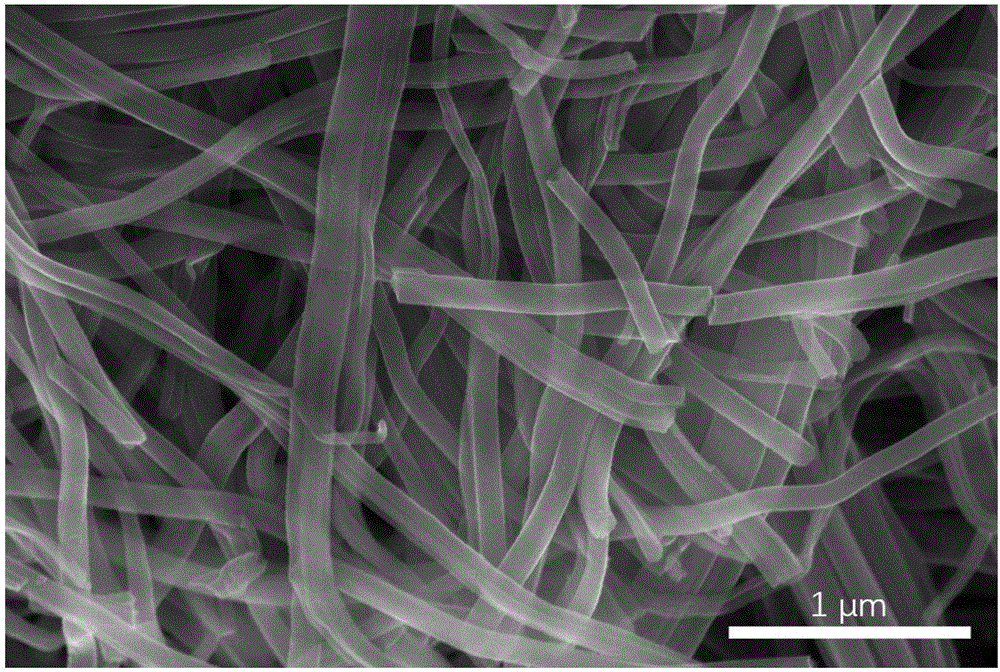

[0038] Take 0.7g KMnO 4 , 1.5g MnSO 4 , dissolved in 70ml of water. The solution was poured into a hydrothermal kettle and kept at 160° C. for 12 hours. After it was cooled to room temperature, the obtained product was washed by suction filtration and dried at 60° C. At this time, one-dimensional nanowire manganese dioxide is obtained.

[0039] Take 400mg of manganese dioxide, 0.38ml of aniline, and 0.29ml of pyrrole, add them into 60ml of water, stir for 20min, put the solution in the refrigerator (3-5°C) and freeze for 30min, take it out and add 15ml of pre-frozen containing 2ml h 2 SO 4The aqueous solution was stirred for 0.5 min, put into the refrigerator (3-5°C) and reacted for 8h, the product was suction filtered until the filtrate was neutral, and dried at 60°C to obtain an intermediate product.

[0040] Take 200 mg of the intermediate product, put it in a tube furnace, and raise the temperature to 900°C at a rate of 5°C / min under a nitrogen atmosphere, keep it war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mesopore | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com