Method for preparing polymerized ferrotitanium water purifying agent by adopting waste metatitanic acid

A technology of metatitanic acid waste and polymerized ferrotitanium, which is applied in the directions of titanium compounds, chemical instruments and methods, iron compounds, etc., can solve the problems of high-efficiency polymerization water treatment agents and other problems, and achieve the effect of easy realization and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

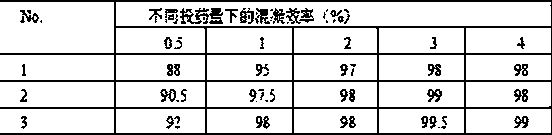

Embodiment 1

[0024] Mix 7.5Kg of metatitanic acid waste with 7.5L of water under low-speed stirring of 30 to 80 rpm and room temperature of 20°C to 30°C to obtain a paste. At a stirring speed of 100 rpm to 200 rpm, add 20L of industrial-grade sulfuric acid solution to the above paste, the mass fraction of sulfuric acid solution is 75%, and the temperature is controlled at 90°C to 100°C for sulfuric acid leaching Take the reaction, and the reaction time is 1 hour to obtain the leachate, which is set aside. At a stirring speed of 300 rpm to 800 rpm, add 20 L of water to the above leaching solution to obtain a diluted solution, and then filter at room temperature to obtain a filtrate for later use. At a stirring speed of 300 rpm to 800 rpm, add 17L of industrial-grade sodium hydroxide solution to the above filtrate to adjust the pH. The mass fraction of sodium hydroxide solution is 20%, and the pH value is controlled at 2. -2.5, to get the conditioning solution. At a stirring speed of 100 r...

Embodiment 2

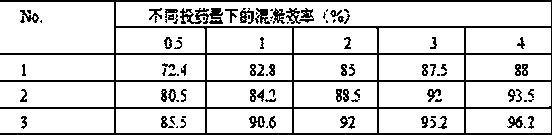

[0026] Mix 7.5Kg of metatitanic acid waste with 7.5L of water under low-speed stirring of 30 to 80 rpm and room temperature of 20°C to 30°C to obtain a paste. At a stirring speed of 100 rpm to 200 rpm, add 18L of industrial-grade sulfuric acid solution to the above paste, the mass fraction of sulfuric acid solution is 75%, and the temperature is controlled at 90°C to 100°C for sulfuric acid leaching Take the reaction, and the reaction time is 1 hour to obtain the leachate, which is set aside. At a stirring speed of 300 rpm to 800 rpm, add 20 L of water to the above leaching solution to obtain a diluted solution, and then filter at room temperature to obtain a filtrate for later use. At a stirring speed of 300 rpm to 800 rpm, add 14L of industrial grade sodium hydroxide solution to the above filtrate to adjust the pH, the mass fraction of sodium hydroxide solution is 20%, and the pH value is controlled at 2 -2.5, to get the conditioning solution. At a stirring speed of 100 re...

Embodiment 3

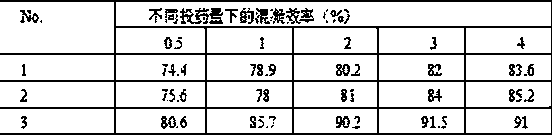

[0028] Mix 15Kg of metatitanic acid waste with 15L of water under low-speed stirring of 30 to 80 rpm and room temperature of 20°C to 30°C to obtain a paste. At a stirring speed of 100 rpm to 200 rpm, add 22L of industrial grade sulfuric acid solution to the above paste, the mass fraction of sulfuric acid solution is 90%, and the temperature is controlled at 90°C to 100°C for sulfuric acid leaching Take the reaction, the reaction time is 2 hours, obtain the leaching solution, and set aside. At a stirring speed of 300 rpm to 800 rpm, add 25 L of water to the above leaching solution to obtain a diluted solution, and then filter at room temperature to obtain a filtrate for later use. At a stirring speed of 300 rpm to 800 rpm, add 19L of industrial grade sodium hydroxide solution to the above filtrate to adjust the pH. The mass fraction of sodium hydroxide solution is 30%, and the pH value is controlled at 1.5 -2, get the conditioning solution. At a stirring speed of 100 rpm to 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com